- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

HOWANN

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

5m*1.3m*1.3m-15m*1.3m*1.4m

-

Weight:

-

2000 kg

-

Product Name:

-

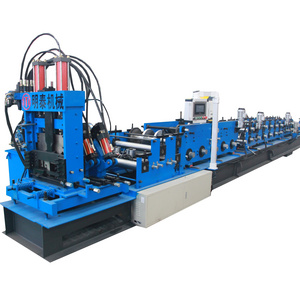

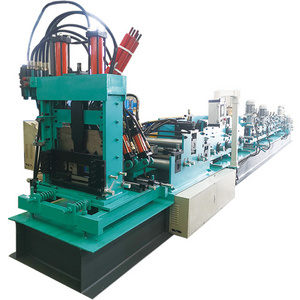

Highway Guardrail Roll FormingMachine

-

Certificate:

-

CE, ISO

-

Shearing punching method:

-

Front punching, rear cutting

-

Reduction mechanism:

-

2 pieces 15kw with No. 9 planetary cycloid reducer

-

Transfer method:

-

Double row 1.5 inch chain drive

-

Shaft diameter material:

-

Material 45#steel HB220-250

-

Number of roller tracks:

-

16 rows

-

Motor power:

-

15kw

-

Pump power:

-

15kw

-

PLC controlling accurancy:

-

±3mm

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Steel

-

Production Capacity:

-

15 m/min

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

HOWANN

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

5m*1.3m*1.3m-15m*1.3m*1.4m

-

Weight:

-

2000 kg

-

Product Name:

-

Highway Guardrail Roll FormingMachine

-

Certificate:

-

CE, ISO

-

Shearing punching method:

-

Front punching, rear cutting

-

Reduction mechanism:

-

2 pieces 15kw with No. 9 planetary cycloid reducer

-

Transfer method:

-

Double row 1.5 inch chain drive

-

Shaft diameter material:

-

Material 45#steel HB220-250

-

Number of roller tracks:

-

16 rows

-

Motor power:

-

15kw

-

Pump power:

-

15kw

-

PLC controlling accurancy:

-

±3mm

Video Description:

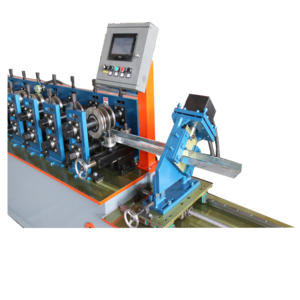

Gauge Stud & Track Ceiling Roll Forming Machine C Channel Purling Roll Forming Machine

Products Description

What is the keel steel roll forming machine?

Keel steel roll forming machine is widely used around the world. This galvanized keel forming machine have two forming lines, but they have seperated control systems, this kind of double line light gauge keel stud track steel roll forming machine will save the space for the factory. And the products this machine produced is mainly used for the drywall and theceiling structure. As a basic material, keel steel is widely used for many aspects as assistant supporters.

Keel steel roll forming machine is widely used around the world. This galvanized keel forming machine have two forming lines, but they have seperated control systems, this kind of double line light gauge keel stud track steel roll forming machine will save the space for the factory. And the products this machine produced is mainly used for the drywall and theceiling structure. As a basic material, keel steel is widely used for many aspects as assistant supporters.

Decoiler -- Feeder -- Roller forming -- Cutting -- Receiving rack -- Packing

Specifications

|

Part details

|

Item Name

|

Specification

|

|

|

|

|

Material

|

Raw material

|

Galvanized steel

|

|

|

|

|

|

Thickness

|

0.3-0.8 mm

|

|

|

|

|

Machine

|

Roller station

|

12

|

|

|

|

|

|

Shaft diameter

|

55 mm

|

|

|

|

|

|

Shaft material

|

45# steel with 0.05mm chrome

|

|

|

|

|

|

Roller material hardness 30-40 HRC

|

Cr 12

|

|

|

|

|

|

Machine size

|

About 4.8×0.8×1 m

|

|

|

|

|

|

Machine weight

|

About 1.8 ton

|

|

|

|

|

|

Machine color

|

As customer' request

|

|

|

|

|

|

Working speed

|

30-50 m/min

|

|

|

|

|

Cutter

|

Hardness

|

50-65 HRC

|

|

|

|

|

|

Cutting tolerance

|

± 1 mm

|

|

|

|

|

|

Material

|

Cr 12

|

|

|

|

|

|

Operate

|

Hydraulic cutting

|

|

|

|

|

Power

|

Driving way

|

Chain 1 inch

|

|

|

|

|

|

Main power

|

4 kw

|

|

|

|

|

|

Pump power

|

3 kw

|

|

|

|

|

|

Voltage

|

380v/50HZ,3P or customize

as customer' request |

|

|

|

|

Control system

|

PLC brand

|

Delta made in Twaiwan

|

|

|

|

|

|

Screen

|

Touchable screen

|

|

|

|

|

|

Language

|

Chinese and English or add language as customer need

|

|

|

|

|

Decoiler

|

Operation

|

Manual

|

|

|

|

|

|

Weight capicatity

|

3 ton

|

|

|

|

|

|

Price

|

Free !

|

|

|

|

|

Receiving table

|

Operation

|

Manual

|

|

|

|

|

|

Length

|

3 m

|

|

|

|

|

|

Price

|

Free !

|

|

|

|

What is the Advantages of our keel steel roll forming machine?

1.PLC Control

You can add in-Line Printing, and PC-Controller Software allowing you to lable components and control your double line light gauge keel stud track c channel steel roll forming machine from your computer. Each option may be included with your machine or added later as your needs evolve

2.Holes (embossing, logo punching)

All double line light gauge keel stud track c channel steel roll forming machines can be set-up with a Service Hole, Dimple Punch, Index/Bolt Hole and Web-notch tools.

3.High speed

Servo driven punch provides close tolerance accuracy and none stop punching for increased production, with interchangeable tooling for different hole sizes and shapes.

1.PLC Control

You can add in-Line Printing, and PC-Controller Software allowing you to lable components and control your double line light gauge keel stud track c channel steel roll forming machine from your computer. Each option may be included with your machine or added later as your needs evolve

2.Holes (embossing, logo punching)

All double line light gauge keel stud track c channel steel roll forming machines can be set-up with a Service Hole, Dimple Punch, Index/Bolt Hole and Web-notch tools.

3.High speed

Servo driven punch provides close tolerance accuracy and none stop punching for increased production, with interchangeable tooling for different hole sizes and shapes.

Product Details

Why Choose Us

Zhengzhou Howann Machinery Co., Ltd.focuses on one-stop service solutions for Metal cold forming machinery. The factory covers an area of 9700 square meters and has 273 employees, including 29 senior engineers and 56 technical personnel. There are total 2 big workshops of Metal processing machinery .Main products: Purlin Forming Machines、gusset plate machine series、Roof/Wall Sheet Forming Machine、Highway Guardrail Roll Forming Machine、Shelf Rack Series Roll Forming Machine、Door and Window Series Roll Forming Machine、Container House Series Cold Roll Forming Machines、Uncoiler/Leveler/Slitter、Shearing/Bending/Rolling Machine、Metal Embossing Machine、Customized Roll Forming Roofing roll formers etc.

What we offer:

1) Good quality control

2) Highly competitive prices

3) state-of-art technology products

4) Best professional team of lifestyle consumer electronics.

5) Smooth communication

6) Effective OEM&ODM service

2) Highly competitive prices

3) state-of-art technology products

4) Best professional team of lifestyle consumer electronics.

5) Smooth communication

6) Effective OEM&ODM service

FQA

1. Who are we?

We are based in Henan, China, start from 2021, sell to North America(30.00%),Central America(20.00%),Eastern

Europe(12.00%),Western Europe(12.00%),Northern Europe(12.00%),Southern Europe (12.00%), South America (2.00%). There are total about 5-10 people in our office.

2. How can we guarantee quality?

Always a pre-production sample before mass production; Always final Inspection before shipment;

3.what can you buy from us?

Tile making machine,Purlin machine,Tapping Machine

4. What is your terms of payment?

For regular order, T/T 30% as deposit, and 70% before Shipment. We'll show you the photos of the products and packages before you pay the balance.

5. How about your delivery time?

Generally, It will take about 7~15 days to send goods out. The specific delivery time depends on the items and the quantity of your order.

We are based in Henan, China, start from 2021, sell to North America(30.00%),Central America(20.00%),Eastern

Europe(12.00%),Western Europe(12.00%),Northern Europe(12.00%),Southern Europe (12.00%), South America (2.00%). There are total about 5-10 people in our office.

2. How can we guarantee quality?

Always a pre-production sample before mass production; Always final Inspection before shipment;

3.what can you buy from us?

Tile making machine,Purlin machine,Tapping Machine

4. What is your terms of payment?

For regular order, T/T 30% as deposit, and 70% before Shipment. We'll show you the photos of the products and packages before you pay the balance.

5. How about your delivery time?

Generally, It will take about 7~15 days to send goods out. The specific delivery time depends on the items and the quantity of your order.

Hot Searches