- Product Details

- {{item.text}}

Quick Details

-

Screw Speed (rpm):

-

600 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

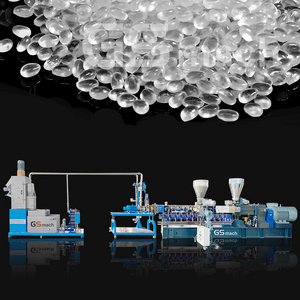

GS Mach

-

Voltage:

-

220V/380V/415V or customized

-

Dimension(L*W*H):

-

10M*2.2M*1.5M

-

Power (kW):

-

90

-

Weight:

-

6000 KG

-

Name:

-

tpu extruder machine

-

After-sales Service Provided:

-

Video Technical Support

-

Usage:

-

Plastic Extrusion

-

Final product:

-

Clean Plastic Granules

-

Motor:

-

SIEMENS Brand

-

Inverter:

-

ABB Brand

-

Machine type:

-

Twin Screw Extrusion Line

-

Automatic Grade:

-

High Automation

-

Certification:

-

CE ISO

-

Feature:

-

High Production Efficiency

Quick Details

-

Screw Design:

-

Double-screw

-

Screw L/D Ratio:

-

48:1

-

Screw diameter (mm):

-

62.4

-

Screw Speed (rpm):

-

600 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

GS Mach

-

Voltage:

-

220V/380V/415V or customized

-

Dimension(L*W*H):

-

10M*2.2M*1.5M

-

Power (kW):

-

90

-

Weight:

-

6000 KG

-

Name:

-

tpu extruder machine

-

After-sales Service Provided:

-

Video Technical Support

-

Usage:

-

Plastic Extrusion

-

Final product:

-

Clean Plastic Granules

-

Motor:

-

SIEMENS Brand

-

Inverter:

-

ABB Brand

-

Machine type:

-

Twin Screw Extrusion Line

-

Automatic Grade:

-

High Automation

-

Certification:

-

CE ISO

-

Feature:

-

High Production Efficiency

Products Description

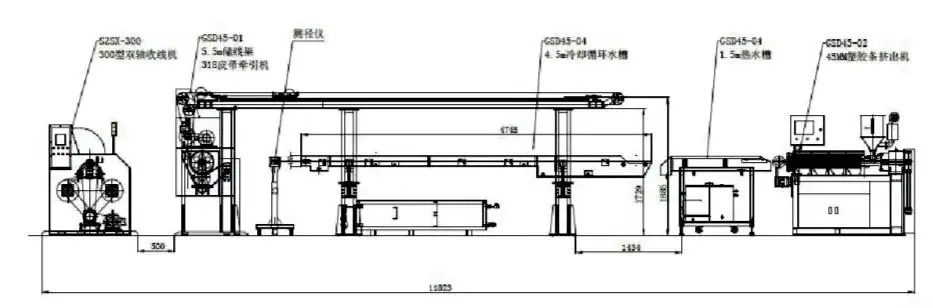

Underwater granulation line

The underwater pelleting system is generally composed of a driving valve, a die head, a pelleting head, a water bypass system and pipe fittings, a particle dryer and a control system. When the uniform high-temperature molten material enters the die flow channel from the end of the upstream equipment (reactor, screw extruder, mixing equipment, etc.), the material is cut into droplets by the high-speed rotating pellet cutter blade when it leaves the die hole and enters the processing water. Due to the physical characteristics of maximizing the specific surface area of the particles and the temperature difference between the molten droplet polymer and the processing water, The droplets solidify and form particles close to spheres. This "first hot and then water-cooled" granulation method determines that it can be well qualified for the granulation operation of materials with poor molten strength, large viscosity and high thermal sensitivity.

Product Paramenters

|

Type

|

Screw Diamter(mm)

|

Power

(kw) |

Rotate speed

(r/m) |

Output

(kg/h) |

|

GS 35

|

35.6

|

11-30

|

600

|

10-120

|

|

GS 50

|

50.5

|

45-90

|

600

|

120-400

|

|

GS 65

|

62.4

|

75-160

|

600

|

200-850

|

|

GS 75

|

71

|

110-250

|

600

|

300-1250

|

|

GS 95

|

93

|

250-550

|

600

|

750-2750

|

Equipment characteristics

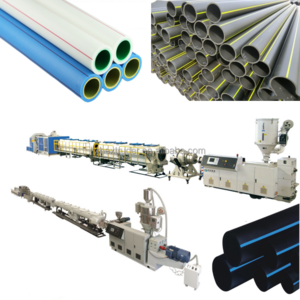

Application

Applicable raw materials:

PE, PP, PS, TR, TPE, TPR, TPV, PET, PVC, EVA, ABS, TPU, EVOH, HMA, HOT MELT GLUE, AS, PMMA, POE, POM, calcium masterbatch, calcium masterbatch, wire material, carbon black masterbatch, black and white masterbatch, etc

Why Choose Us

Contact us

Hot Searches