- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

140

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Online support, Field installation, commissioning and training, Field maintenance and repair service

-

Keyword:

-

jewelry polishing machine used

-

Application:

-

metal deburring and polishing

-

Voltage:

-

220V/380V/415V/440V

-

Material:

-

Gold and silver

-

Certification:

-

ISO9001:2015

-

Usage:

-

Metal Surface Polishing

-

Model:

-

VA

-

Type:

-

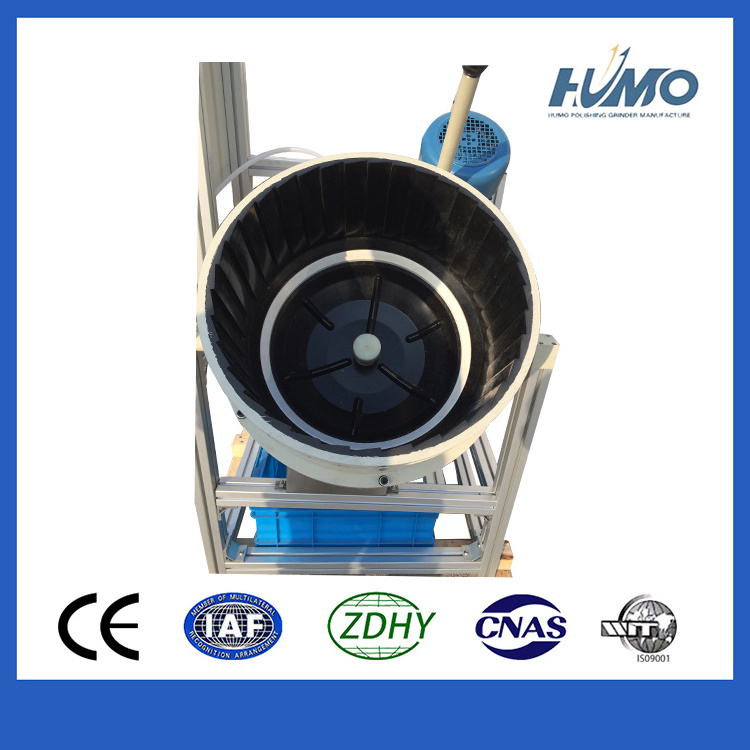

Centrifugal disc finishing machine

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

HUMO

-

Power (kW):

-

0.75

-

Weight (KG):

-

140

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Online support, Field installation, commissioning and training, Field maintenance and repair service

-

Keyword:

-

jewelry polishing machine used

-

Application:

-

metal deburring and polishing

-

Voltage:

-

220V/380V/415V/440V

-

Material:

-

Gold and silver

-

Certification:

-

ISO9001:2015

-

Usage:

-

Metal Surface Polishing

-

Model:

-

VA

-

Type:

-

Centrifugal disc finishing machine

Feature:

1.Compact design suit both wet and dry process

2.Process containers with hot molded PU lining

3.The bearing selected the wear resistant ceramic/tungsten alloy ring

4.High quality gap adjusting system

5.Speed control with frequency inverter

6.Automatic water recycling device

1.Compact design suit both wet and dry process

2.Process containers with hot molded PU lining

3.The bearing selected the wear resistant ceramic/tungsten alloy ring

4.High quality gap adjusting system

5.Speed control with frequency inverter

6.Automatic water recycling device

|

Model

|

Capacity(L)

|

Size

L×W×H(mm) |

Motor(kw)

|

Weight(kg)

|

Speed(rpm)

|

|

VA20

|

20L

|

720×800×1450

|

0.75kw

|

140

|

450

|

|

VA20/2

|

20×2L

|

1180×800×1450

|

2×0.75kw

|

235

|

450

|

|

VA20/3

|

20×3L

|

1700×800×1450

|

3×0.75kw

|

330

|

450

|

|

VA38

|

38L

|

900×820×1450

|

2.20 kw

|

220

|

400

|

|

VA38/2

|

38×2L

|

1500×820×1450

|

2×2.20 kw

|

370

|

400

|

|

VA38/3

|

38×3L

|

2150×820×1450

|

3×2.20 kw

|

530

|

400

|

|

VA50

|

50L

|

1450×2000×2350

|

2.2 kw

|

650

|

380

|

FAQ

Our laboratory services are available to you at no cost. Mass Finishing and determination of Process Capability allows you to use the right media to ensure consistent production capability and built-in reproducibility of your manufacturing processes. We will work with you to determine the best media and the best processes for your parts. This step can result in:

* Reduced Cycle Times

* Improved RMS Finishes

* Reduced Finishing Costs

* Access to Latest Technology

* R & D for Special Process Media

Mass Finishing describes a mechanical process where large amounts of parts are economically processed to achieve one or several surface improvement functions. These surface improvement functions include:

* Cleaning

* Deburring

* Surface refinement

* Inhibiting

* Drying

These functions are not independent of each other. It is common to have several or all of these functions take place in a single mass finishing process.

Process Capability is the measured, built-in reproducibility of the product turned out by the process. Such a determination is made using statistical data, not wishful thinking. Statistically determined limits are compared to specification limits to decide if a process can consistently produce acceptable product. Process capability is best established through closely monitored testing and recording of data over a set period of actually production.

* Reduced Cycle Times

* Improved RMS Finishes

* Reduced Finishing Costs

* Access to Latest Technology

* R & D for Special Process Media

Mass Finishing describes a mechanical process where large amounts of parts are economically processed to achieve one or several surface improvement functions. These surface improvement functions include:

* Cleaning

* Deburring

* Surface refinement

* Inhibiting

* Drying

These functions are not independent of each other. It is common to have several or all of these functions take place in a single mass finishing process.

Process Capability is the measured, built-in reproducibility of the product turned out by the process. Such a determination is made using statistical data, not wishful thinking. Statistically determined limits are compared to specification limits to decide if a process can consistently produce acceptable product. Process capability is best established through closely monitored testing and recording of data over a set period of actually production.

Hot Searches