- Product Details

- {{item.text}}

Quick Details

-

No. of Slitting Lines:

-

5 - 25

-

Coil Weight (T):

-

20 T

-

Place of Origin:

-

China

-

Voltage:

-

380V/50HZ

-

Rated Power:

-

300KW

-

Dimension(L*W*H):

-

30x2x2m

-

Weight:

-

5000

-

Product name:

-

heavy gauge slitting line machine

-

Material:

-

SS,CR,HR,GI,AL,Copper,Special steel etc

Quick Details

-

Cutting Width (mm):

-

50 - 5000 mm

-

Material Thickness(mm):

-

0.2 - 3 mm

-

Cutting Speed(m/min):

-

10 - 100 mm

-

No. of Slitting Lines:

-

5 - 25

-

Coil Weight (T):

-

20 T

-

Place of Origin:

-

China

-

Voltage:

-

380V/50HZ

-

Rated Power:

-

300KW

-

Dimension(L*W*H):

-

30x2x2m

-

Weight:

-

5000

-

Product name:

-

heavy gauge slitting line machine

-

Material:

-

SS,CR,HR,GI,AL,Copper,Special steel etc

Slitting Line Carbon Steel Stainless Strip Splitting Line Steel Coil Slitting Machine

A Steel Strip Slitting Machine, often referred to simply as a slitter, is a specialized industrial equipment used in the metal

processing and manufacturing industry. Its primary purpose is to cut large coils of steel, or other metal materials, into narrower

strips or coils of smaller width. This process is essential for various industries that require steel or metal strips of precise

dimensions for their production processes, such as the automotive, construction, appliance, and metal fabrication industries.

Here are some key features and functions of a Steel Strip Slitting Machine:

1. Coil Feeding: T he machine is equipped with a mechanism to feed large coils of steel into the slitting area. This can be done manually or automatically, depending on the specific machine's design.

2. Slitting Process: The heart of the machine is the slitting process, which involves multiple circular blades or rotary knives. These blades cut the wide coil into narrower strips as per the desired width specifications. The machine allows for accurate and consistent strip width.

3. Tension Control: T o prevent material deformation and ensure a smooth, straight cut, the machine employs tension control systems. These systems maintain constant tension on the material as it passes through the slitting process.

4. Recoiling: After slitting, the individual strips are wound onto separate recoiler shafts. These recoiler shafts can be

adjusted to maintain the correct tension, preventing coiling defects.

5. Edge Trimming: In some cases, a slitting machine can also be equipped with edge-trimming mechanisms to ensure the edges of the strips are clean and free from burrs or irregularities.

6. Unloading: Once the strips are cut and rewound, they can be unloaded for further processing or transportation.

7. Automation: Many modern slitting machines are highly automated, with computer control systems that allow for precise adjustment of the slitting width, tension, and other parameters. This automation improves efficiency and reduces the risk of errors.

The precise specifications and capabilities of a Steel Strip Slitting Machine can vary depending on its design and intended use.Some machines are capable of handling a wide range of materials, including different types of metals, while others are specialized for specific applications.

In summary, Steel Strip Slitting Machines play a crucial role in the metal processing industry by providing a cost-effective and efficient way to convert large coils of steel into smaller, manageable strips of precise dimensions, meeting the needs of various downstream industries.

processing and manufacturing industry. Its primary purpose is to cut large coils of steel, or other metal materials, into narrower

strips or coils of smaller width. This process is essential for various industries that require steel or metal strips of precise

dimensions for their production processes, such as the automotive, construction, appliance, and metal fabrication industries.

Here are some key features and functions of a Steel Strip Slitting Machine:

1. Coil Feeding: T he machine is equipped with a mechanism to feed large coils of steel into the slitting area. This can be done manually or automatically, depending on the specific machine's design.

2. Slitting Process: The heart of the machine is the slitting process, which involves multiple circular blades or rotary knives. These blades cut the wide coil into narrower strips as per the desired width specifications. The machine allows for accurate and consistent strip width.

3. Tension Control: T o prevent material deformation and ensure a smooth, straight cut, the machine employs tension control systems. These systems maintain constant tension on the material as it passes through the slitting process.

4. Recoiling: After slitting, the individual strips are wound onto separate recoiler shafts. These recoiler shafts can be

adjusted to maintain the correct tension, preventing coiling defects.

5. Edge Trimming: In some cases, a slitting machine can also be equipped with edge-trimming mechanisms to ensure the edges of the strips are clean and free from burrs or irregularities.

6. Unloading: Once the strips are cut and rewound, they can be unloaded for further processing or transportation.

7. Automation: Many modern slitting machines are highly automated, with computer control systems that allow for precise adjustment of the slitting width, tension, and other parameters. This automation improves efficiency and reduces the risk of errors.

The precise specifications and capabilities of a Steel Strip Slitting Machine can vary depending on its design and intended use.Some machines are capable of handling a wide range of materials, including different types of metals, while others are specialized for specific applications.

In summary, Steel Strip Slitting Machines play a crucial role in the metal processing industry by providing a cost-effective and efficient way to convert large coils of steel into smaller, manageable strips of precise dimensions, meeting the needs of various downstream industries.

Product Overview

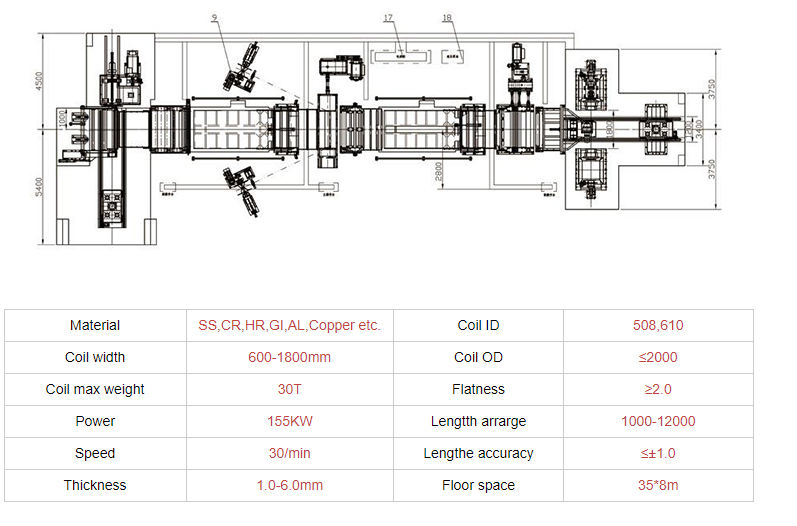

PRODUCT SPECIFICATIONS

Hot Searches