- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

CJL

-

Effective Volume:

-

10-15CBM

-

Dimension(L*W*H):

-

11.5*1.5*2.2m

-

Voltage:

-

220v/380v, customized

-

Power:

-

20KW

-

Weight (KG):

-

6000

-

Raw material:

-

Coconut Shell Wood Sawdust Briquette

-

Product name:

-

Continuous Carbonization Furnace

-

Usage:

-

Charcoal Maker

-

Advantage:

-

Continuous Working Environment Friendly

-

Keywords:

-

Carbonization Furnace Wood Charcoal

-

Capacity:

-

300-1200KG/H

-

Color:

-

Customer's Request

-

Final product usage:

-

Make Shisha Bbq Charcoal Briquettes

-

Feature:

-

High Carbonizing Efficiency

-

Instalation:

-

Engineer Guide

Quick Details

-

Place of Origin:

-

HENAN

-

Marketing Type:

-

Hot Product 2023

-

Core Components:

-

PLC, Engine, Bearing, Motor, Gear

-

Brand Name:

-

CJL

-

Effective Volume:

-

10-15CBM

-

Dimension(L*W*H):

-

11.5*1.5*2.2m

-

Voltage:

-

220v/380v, customized

-

Power:

-

20KW

-

Weight (KG):

-

6000

-

Raw material:

-

Coconut Shell Wood Sawdust Briquette

-

Product name:

-

Continuous Carbonization Furnace

-

Usage:

-

Charcoal Maker

-

Advantage:

-

Continuous Working Environment Friendly

-

Keywords:

-

Carbonization Furnace Wood Charcoal

-

Capacity:

-

300-1200KG/H

-

Color:

-

Customer's Request

-

Final product usage:

-

Make Shisha Bbq Charcoal Briquettes

-

Feature:

-

High Carbonizing Efficiency

-

Instalation:

-

Engineer Guide

|

Biochar pyrolysis kiln/Rice husk activated carbon furnaces/large carbonation furnace biochar pyrolysis for sale

|

|

|

|

|

||||

Product Description

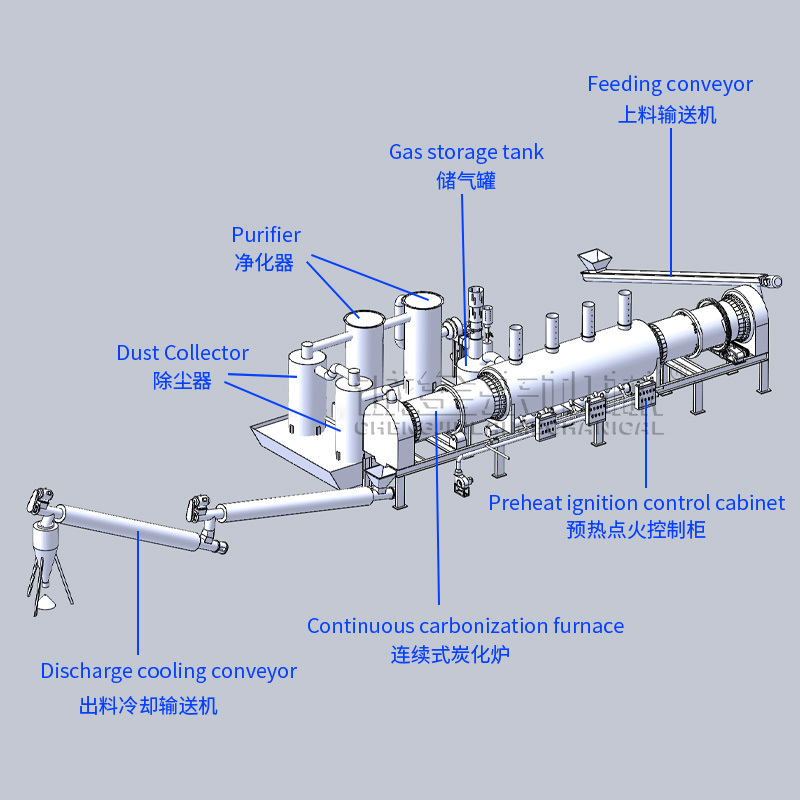

Continous carbonization furnace

Continuous carbonization furnace is an energy-saving, environmental-protection and high efficient equipment.

It can carbonize different materials into charcoal, such as sawdust, wood chips, rice husk, sugarcane bagasse,etc.

Available raw materials for charcoal making machine:

▶ All organic waste in nature.

▶ Biomass waste (wood chips, branches, sawdust, bamboo, etc); agricultural waste (rice husk/hull, coconut shell, palm kernel shell, olive shell, coffee shell, straws, bagasse); human waste; kitchen garbage (mostly fruit peels); animal waste; etc.

▶ All organic waste in nature.

▶ Biomass waste (wood chips, branches, sawdust, bamboo, etc); agricultural waste (rice husk/hull, coconut shell, palm kernel shell, olive shell, coffee shell, straws, bagasse); human waste; kitchen garbage (mostly fruit peels); animal waste; etc.

|

Raw materials

|

Any Carbon-containing organic materials can be as raw materials , such as sawdust, rice hulls, sawdust, bamboo, palm shells,peanut shells, coconut shells, stalks, stalks, etc.(

raw materials size < 15mm

)

|

|

Main Feature

|

1 during the carbonize process, it will have Combustion gases such as carbon monoxide, methane, hydrogen, etc,which can be rec

ycled , purified and circulated burning as heating source of the whole line machine 2 so that the whole set of equipment will not pollute the environment when working, but also provide its own heating use energy . which is a high efficiency equipment |

|

Heating Source

|

biomass fuel as heating

or

natural gas heating

|

Work Principle:

1 this whole line includes

biomass gas furnace, flue gas purifier, flue gas condenser, fan, self-adapter burner, horizontal carbonization furnace,

etc.

2 This machine is used - dry carbonization method. The combustion gases such as carbon monoxide, methane, hydrogen, etc. produced by the carbonization process are fully utilized, and the pure combustible gas is obtained by separating the wood tar and wood vinegar from the flue gas purification system. After burning fully by self-equipped burner, to supply the main parts’ heating need(temperature control in 600 degrees)

3 outlet with a separate combustible gas recovery pipeline, carbonization of the material at high temperature carbonization,decomposition of carbon monoxide, methane, hydrogen and other combustible gases, through the recovery of the pipeline, flue gas purification system, burner heating cylinder, to cycle heating.

2 This machine is used - dry carbonization method. The combustion gases such as carbon monoxide, methane, hydrogen, etc. produced by the carbonization process are fully utilized, and the pure combustible gas is obtained by separating the wood tar and wood vinegar from the flue gas purification system. After burning fully by self-equipped burner, to supply the main parts’ heating need(temperature control in 600 degrees)

3 outlet with a separate combustible gas recovery pipeline, carbonization of the material at high temperature carbonization,decomposition of carbon monoxide, methane, hydrogen and other combustible gases, through the recovery of the pipeline, flue gas purification system, burner heating cylinder, to cycle heating.

4 The initial carbonization ignition is provided by the biomass gas furnace.

Raw material & Final products

Final Products Applications:

Widely used as the fuel of BBQ,

the fuel in other industries,

attach heavy metal to improve the quality of the soil.

Widely used as fuel in industries such as steel and iron factories, ceramics, etc.

2.

Biogas

Widely used as fuel,g

reenhouse agriculture heating,c

an be used for the generator to get electricity.

3.Wood vinegar, Tar

The great materials in shipbuilding and paint industry,r

aw materials in chemical and medicine field,u

sed as plant nutrition regulates auxin or insecticide.

Specification

|

Equipment model of carbonization furnace

|

BDTHL- I

|

BDTHL-Ⅱ

|

BDTHL-Ⅲ

|

|

Pipe diameter/mm

|

800×1200

|

1000×1500

|

1200×1800

|

|

Equipment output/kg/h

|

500-600

|

800-1000

|

1200-1500

|

|

Liquefied gas burner/unit

|

6

|

6

|

6

|

|

Main burner/unit

|

1

|

1

|

1

|

|

Auxiliary burner/unit

|

1

|

1

|

1

|

|

Fan/kW

|

7.5

|

11

|

15

|

|

Air distribution fan/kW

|

3

|

3

|

3

|

|

Carbonization machine host/kw

|

4

|

5.5

|

7.5

|

|

Spiral feeding machine/kw

|

4

|

4

|

4

|

|

Cooling carbon extractor/kw

|

3

|

3

|

3

|

|

Furnace temperature/℃

|

350-850

|

350-850

|

350-850

|

|

Carbonization pipeline temperature/℃

|

500-800

|

500-800

|

500-800

|

Packing & Delivery

Hot Searches