▶

50years

of R & D and production experience in laser industry

▶

F

ast delivery

,Smart factory standardized production

▶

Global after-sales

, door-to-door within 1 day

▶ 3

-year warranty

and professional local after-sales service

▶

Cost-effective

HGSTAR focus on high quality and inexpensive

- Product Details

- {{item.text}}

Quick Details

-

Throat Depth (mm):

-

400 mm

-

Width of Working Table (mm):

-

1860 mm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

HGSTAR

-

Year:

-

2023

-

Weight (KG):

-

2000

-

Motor Power (kw):

-

18 kw

-

Marketing Type:

-

New Product 2024

-

Product name:

-

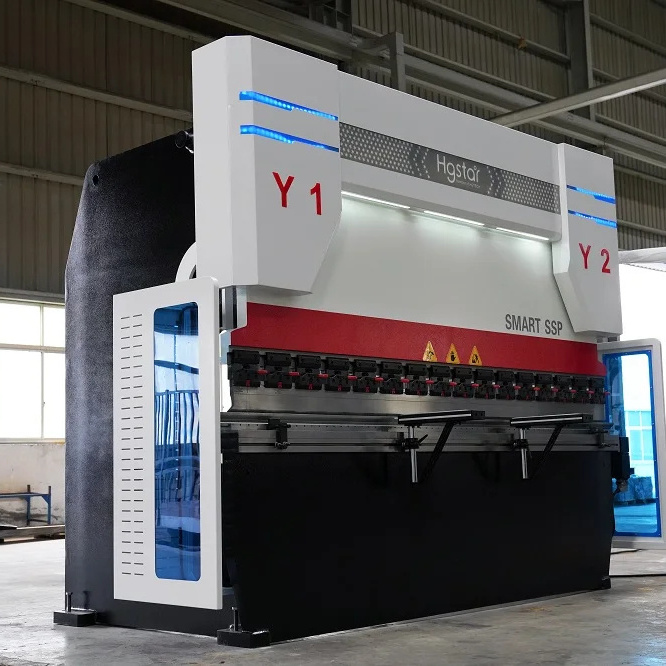

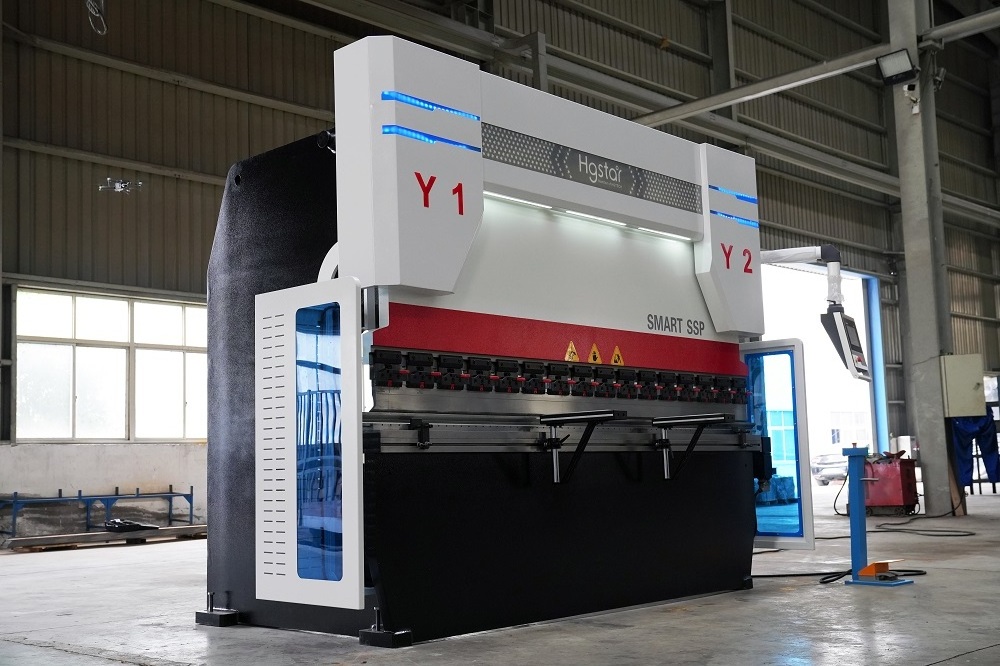

HGSTAR Cnc Bending Machine

-

Keyword:

-

Cnc Bending Machine

-

Application:

-

Metal Sheet Bending

-

After-sales Service Provided:

-

Service Machinery Overseas

-

Type:

-

Metal Bender Tools

-

CNC or not:

-

CNC Bender Machine

-

Brand:

-

HGSTAR

-

Color:

-

Red + White

-

Item:

-

CNC Bending Machine

-

Cylinder Stroke:

-

200mm

Quick Details

-

Machine Type:

-

Synchronized

-

Length of Working Table (mm):

-

4250

-

Slider Stroke (mm):

-

200 mm

-

Throat Depth (mm):

-

400 mm

-

Width of Working Table (mm):

-

1860 mm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

HGSTAR

-

Year:

-

2023

-

Weight (KG):

-

2000

-

Motor Power (kw):

-

18 kw

-

Marketing Type:

-

New Product 2024

-

Product name:

-

HGSTAR Cnc Bending Machine

-

Keyword:

-

Cnc Bending Machine

-

Application:

-

Metal Sheet Bending

-

After-sales Service Provided:

-

Service Machinery Overseas

-

Type:

-

Metal Bender Tools

-

CNC or not:

-

CNC Bender Machine

-

Brand:

-

HGSTAR

-

Color:

-

Red + White

-

Item:

-

CNC Bending Machine

-

Cylinder Stroke:

-

200mm

Product Paramenters

|

Machine Model

|

SSP Series CNC Bending Machine

|

|

Slide Stroke (mm)

|

200

|

|

Throat Depth (mm)

|

400

|

|

Length of Working Table (mm)

|

4250

|

|

Width of Working Table (mm)

|

1960

|

|

Automatic Level

|

Fully Automatic

|

|

Machine Type

|

Synchronized

|

|

Material/Metal Processed

|

Brass/Copper, Stainless steel, ALLOY, Carbon steel, Aluminum

|

|

Weight (KG)

|

2000

|

|

Motor Power (kw)

|

18

|

|

Warranty of Core Components

|

5 Years

|

|

After-sales Service

|

Provided

|

Products Description

Product description:

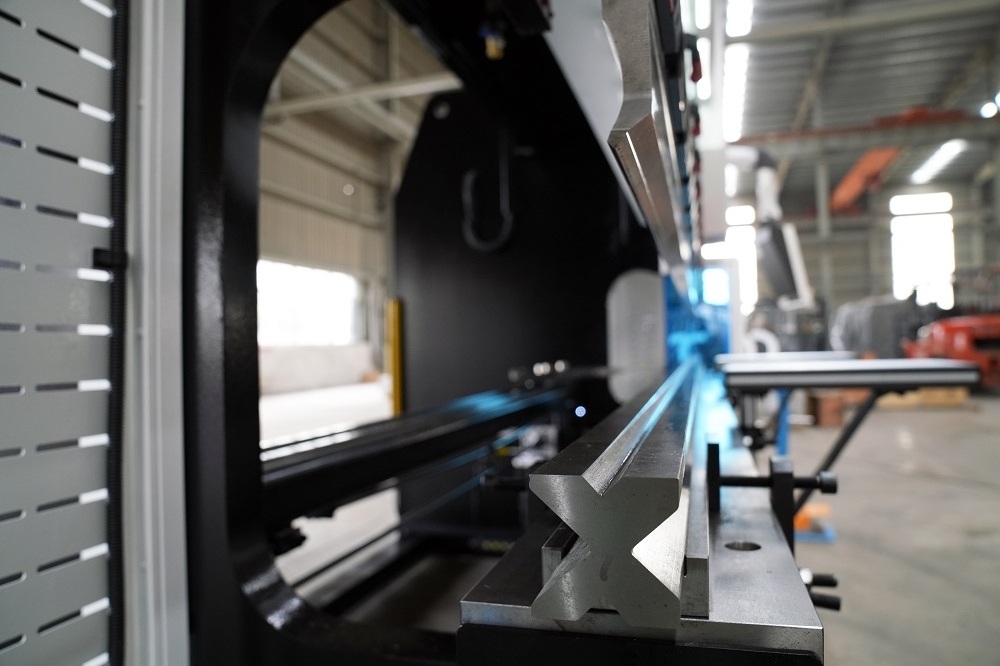

1. The frame adopts whole welding structure, and by the fireplace tempering treatment, machine tool accuracy is good.

2. Hydraulic pressure type, step less pressure adjustment, using high quality imported sealing ring, to ensure the reliability of the machine tool.

3. Mechanical synchronization, using the upper and lower composite compensation structure, improve the machining accuracy of parts. (more than 160 tons for the working table compensation structure)

4. Adjust the slider stroke and adjust the position of the rear gear, use the electric quick adjustment and manual adjustment.

5. The machine tool is a little move, a single, continuous operation standard.

6. The machine tool is equipped with a safety protection bar and open door with power down device, which improves the safety ofoperation. (40 tons or more than 200 tons of no guard rails)

|

No.

|

Configuration

|

Configuration

|

Numerical value

|

Unit

|

Remark

|

|||

|

1

|

Nominal pressure

|

Nominal pressure

|

1350

|

KN

|

|

|||

|

2

|

Foldable plate width

|

|

3200

|

mm

|

|

|||

|

3

|

Slide stroke

|

|

200

|

mm

|

|

|||

|

4

|

Maximum opening height

|

|

420

|

mm

|

|

|||

|

5

|

Column spacing

|

|

2700

|

mm

|

|

|||

|

6

|

Throat depth

|

|

400

|

mm

|

|

|||

|

7

|

Fast down speed

|

|

160

|

mm/ s

|

|

|||

|

8

|

Return speed

|

|

130

|

mm/ s

|

|

|||

|

9

|

Working speed

|

|

10

|

mm/ s

|

|

|||

|

10

|

Main motor power

|

|

11

|

Kw

|

servo motor

|

|||

|

11

|

CNC system

|

|

DA53T

|

|

Netherlands

|

|||

|

12

|

X-axis travel of rear stopper

|

|

500

|

mm

|

|

|||

|

13

|

Number of control axes

|

|

4+ 1 Axis (Y1 ,Y2 ,X ,R+V)

|

|

|

|||

|

14

|

Machine

tool accuracy

|

Slider repeat accuracy

|

≤±0.01

|

mm

|

|

|||

|

15

|

|

Slide positioning accuracy

|

≤±0.02

|

mm

|

|

|||

|

16

|

|

Workpiece straightness

|

0.3/m

|

mm

|

|

|||

|

17

|

|

Bending angle error

|

<±30

|

|

|

|||

|

18

|

|

Raster scale resolution

|

0.005

|

mm

|

|

|||

|

19

|

Rear retaining material

|

X-axis travel

|

500

|

mm

|

|

|||

|

20

|

|

X-axis speed

|

200

|

mm/ s

|

|

|||

|

21

|

|

Positioning accuracy

|

±0.05

|

mm

|

|

|||

|

22

|

|

Repetitive positioning accuracy

|

±0.015

|

mm

|

|

|||

|

23

|

Machine wight

|

|

10

|

t

|

|

|||

|

24

|

Machine diamentions

|

|

L*W*H

3500*1580 *2500

|

mm

|

|

|||

Hot Searches