- Product Details

- {{item.text}}

Quick Details

-

EINECS No.:

-

TQ2700000

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Kafuter

-

Model Number:

-

NS-084-2

-

appearance:

-

Grey elastomer

-

Shore hardness:

-

63Shore A

-

Dielectric loss (1MHz):

-

2.1x10-3

-

Relative permittivity (1MHz):

-

3.25

-

Breakdown strength:

-

20kV/mm

-

thermal conductivity:

-

0.8W/(m.K)

Quick Details

-

CAS No.:

-

63394-02-05

-

Other Names:

-

potting glue

-

MF:

-

SiO2

-

EINECS No.:

-

TQ2700000

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Kafuter

-

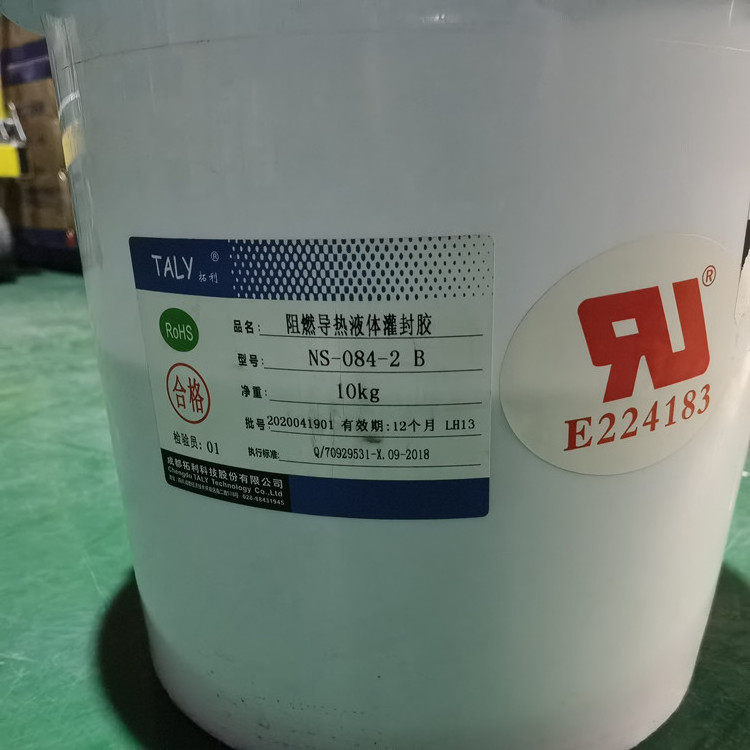

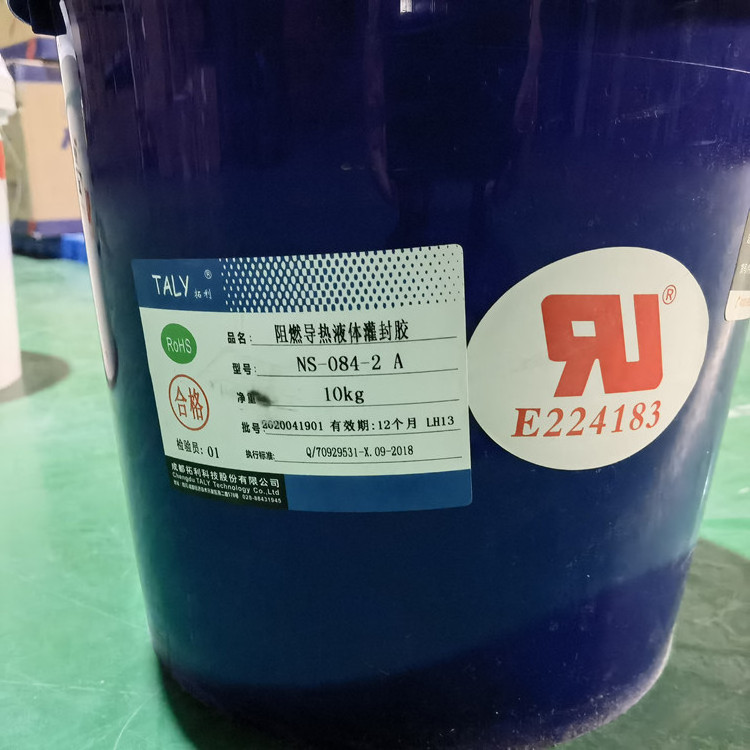

Model Number:

-

NS-084-2

-

appearance:

-

Grey elastomer

-

Shore hardness:

-

63Shore A

-

Dielectric loss (1MHz):

-

2.1x10-3

-

Relative permittivity (1MHz):

-

3.25

-

Breakdown strength:

-

20kV/mm

-

thermal conductivity:

-

0.8W/(m.K)

Product Description

Product introduction

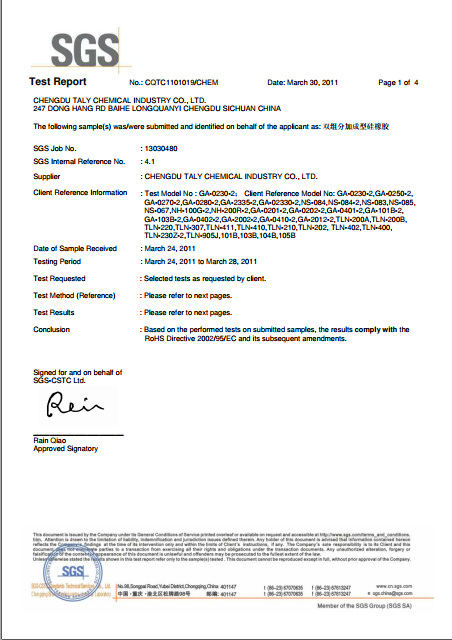

Ns-084-2 is a kind of two-component addition liquid silicone rubber specially designed for encapsulation of electronic and

electrical components.Ns-084-2 product has good fluidity before curing; when it is used, the two components are mixed in equal proportion, and the operation time is moderate; there is no small molecule by-products released during curing, and the shrinkage rate is small; after curing, it has good high and low temperature resistance (- 60 ~ 200 ℃), high thermal conductivity, excellent flame retardancy and excellent electrical performance.

When used, the two components can be mixed evenly according to a: B = 100:100 (weight ratio or volume ratio). The product can be cured at room temperature and high temperature. It is non corrosive to metal and non-metal materials, and can be cured at the same time in the inner and outer deep layers. , ceramics, glass, gem bonding.

Ns-084-2 is a kind of two-component addition liquid silicone rubber specially designed for encapsulation of electronic and

electrical components.Ns-084-2 product has good fluidity before curing; when it is used, the two components are mixed in equal proportion, and the operation time is moderate; there is no small molecule by-products released during curing, and the shrinkage rate is small; after curing, it has good high and low temperature resistance (- 60 ~ 200 ℃), high thermal conductivity, excellent flame retardancy and excellent electrical performance.

When used, the two components can be mixed evenly according to a: B = 100:100 (weight ratio or volume ratio). The product can be cured at room temperature and high temperature. It is non corrosive to metal and non-metal materials, and can be cured at the same time in the inner and outer deep layers. , ceramics, glass, gem bonding.

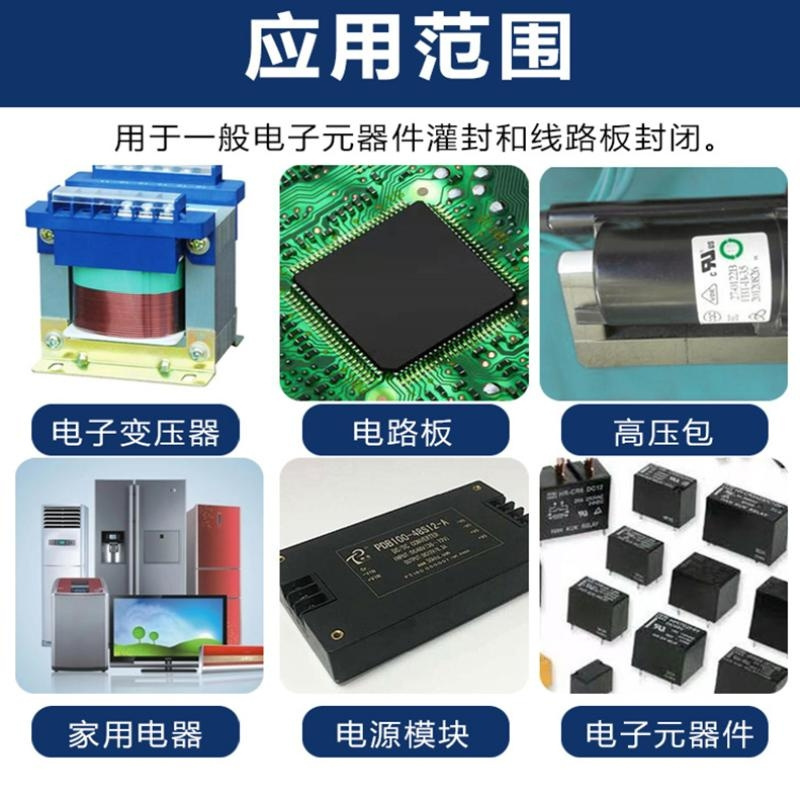

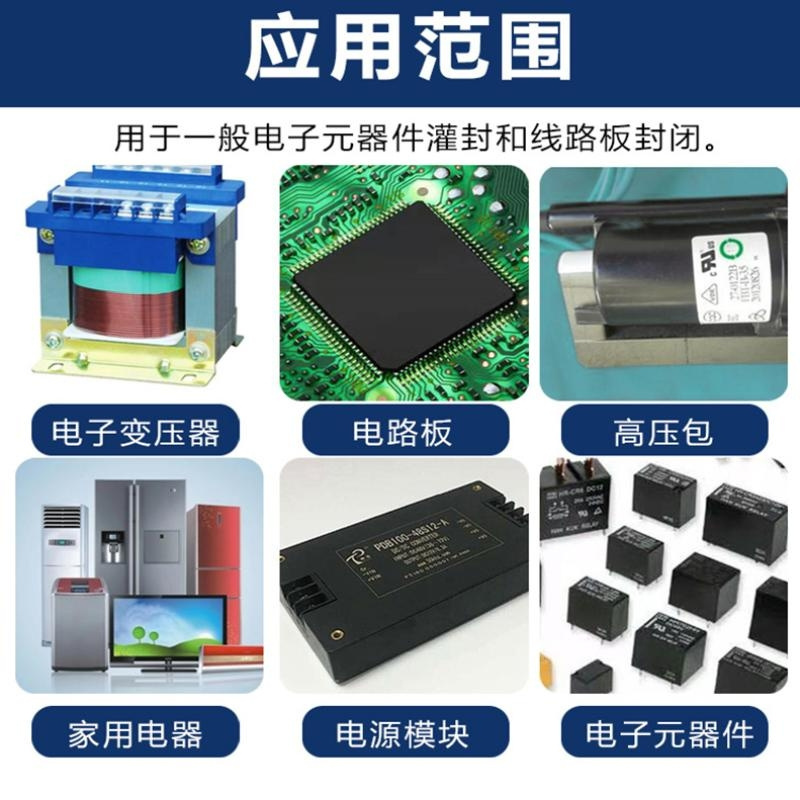

Typical use

This product is mainly used for encapsulation of electronic components with weather resistance, insulation and high heat

dissipation requirements.For example, the insulation, heat dissipation and temperature resistance potting of various

specifications of communication modules, micro transformers and all-in-one transformers can resist high temperature, insulation, sealing, waterproof, environmental pollution, eliminate stress and all kinds of vibration, and achieve the purpose of long-term and reliable protection of sensitive circuits and components

This product is mainly used for encapsulation of electronic components with weather resistance, insulation and high heat

dissipation requirements.For example, the insulation, heat dissipation and temperature resistance potting of various

specifications of communication modules, micro transformers and all-in-one transformers can resist high temperature, insulation, sealing, waterproof, environmental pollution, eliminate stress and all kinds of vibration, and achieve the purpose of long-term and reliable protection of sensitive circuits and components

Usage and precautions

Before mixing, each component shall be thoroughly stirred, and then component A and component B shall be weighed in proportion, and fully mixed in a clean container. After removing all bubbles under vacuum, it can be potted.The surface of the component to be potted should be clean. When potting, it should be poured into the component to be potted slowly, so as to prevent bubbles from being entrained due to potting, which will affect the insulation.

For the automatic filling and sealing production line, each component can be thoroughly stirred, and then the bubbles can be removed by vacuum respectively (the time of removing bubbles is about 30 minutes)

Before mixing, each component shall be thoroughly stirred, and then component A and component B shall be weighed in proportion, and fully mixed in a clean container. After removing all bubbles under vacuum, it can be potted.The surface of the component to be potted should be clean. When potting, it should be poured into the component to be potted slowly, so as to prevent bubbles from being entrained due to potting, which will affect the insulation.

For the automatic filling and sealing production line, each component can be thoroughly stirred, and then the bubbles can be removed by vacuum respectively (the time of removing bubbles is about 30 minutes)

Hot Searches