- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V 50Hz

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Jinggang

-

Model Number:

-

TJ-30

-

Dimensions(L*W*H):

-

650 * 650 * 900mm

-

Weight:

-

130 KG

-

After-sales Service Provided:

-

No overseas service provided

-

feeding:

-

Motor Drive

-

Stamping plate area:

-

290 * 210mm

-

Table size:

-

400 * 320mm

-

maximum pressure:

-

4000kg

-

The vertical stroke:

-

40mm

-

heating power:

-

1600W

-

Stroke:

-

40mm

-

Packing size:

-

650*650*900mm

-

Packing weight:

-

175KG

Quick Details

-

Condition:

-

New

-

Plate Type:

-

Flatbed Printer

-

Color & Page:

-

single color

-

Voltage:

-

220V 50Hz

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Jinggang

-

Model Number:

-

TJ-30

-

Dimensions(L*W*H):

-

650 * 650 * 900mm

-

Weight:

-

130 KG

-

After-sales Service Provided:

-

No overseas service provided

-

feeding:

-

Motor Drive

-

Stamping plate area:

-

290 * 210mm

-

Table size:

-

400 * 320mm

-

maximum pressure:

-

4000kg

-

The vertical stroke:

-

40mm

-

heating power:

-

1600W

-

Stroke:

-

40mm

-

Packing size:

-

650*650*900mm

-

Packing weight:

-

175KG

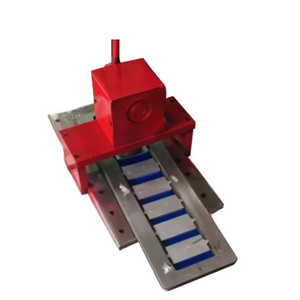

TJ-30 Manual car license plate making machine number plate press machine embossing stamping machine for sale

Quality/safety security:ISO9001-2000&CE

Product description

Here we offer you an advanced Hot Foil Stamping Machine which is designed for leather printing. Other industry usages include hot foil stamping, embossing or logo heat transfer on paper , leather , rubber, plastics and wood products , etc.

It is an optimal equipment for your individual workshop or small-sized enterprise.

Technical Details

Advantages

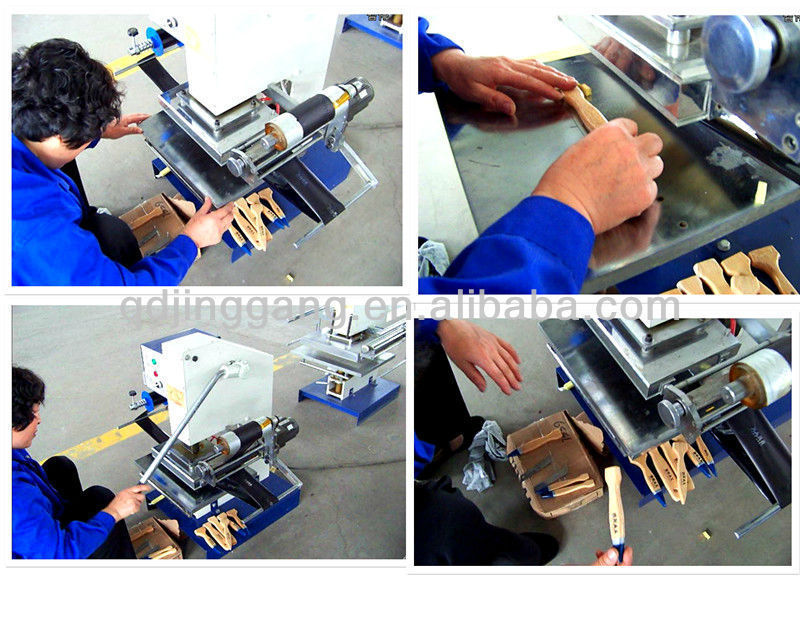

1. This machine is widely used for stamping foil pattern on all kinds of cards,wood, paper, leather,

plastic,rubber, photos and various hard packages of food and cosmetics.

2. Based on lever-type design,the pressure is strong, quality of stamping is excellent.

3. Easy to learn and safe to operate, its speed of heating is fast and the power consumption is low .

4. The stamping pressure,temperature,transfer time and the height of workbench can be adjusted flexibly.

5. R elay controls operation, thermostat adjusts the steady temperature for easy and safe operation.

6. Automatic feeding and the collecting stamping foils,save manpower.

7.Good technical guidance and after-sales service will be provided by our prefessional team .

8.Good raw materials ensure the excellent durability and printing effect.

Note:We can manufacture the improved stamping machines by the customer's demand.

Hot stamping temperature reference

|

Paper |

PVC |

soft plastic |

Hard plastic artificial leather |

Synthetic leather |

|

85-120 °C |

65-80 °C |

75-85 °C |

120-150 °C |

160-180 °C |

Matters needing attention duiring hot stamping machine process

(1). According to the different varieties of scalded object, select the appropriate hot stamping foil.Good sized must master the temperature, pressure, stamping speed three party coordination,

and according to the short-run printing materials, area of difference

(2).The cutting knife should grasp the direction and speed of car;

(3).The anodized hot stamping foil should choose attributes suitable paper, ink (especially black kerosene, composite glue, hot stamping parts must be kept dry, so as to avoid the bronzing layer oxidizing or injury;

(4). The general packaging: 0, 64 × 120m volumes, each volume 10: a box can be custom width of 0.64M, length of 240m or 360m rolls or other special specifications;

(5). When stored to prevent pressure, moisture, heat, sunscreen, placed in a cool ventilated place.

Product show of manual hot stamping machine

Work Process of hot stamping machine

Samples made by hot stamping machine

Packing and delivery of hot stamping machine (complete wood box packing avoid machine damage or parts missing):

Our factory and customers

Which machines do you need?

Tell me some information about your demand or a picture of the sample ,and I will give you the prompt feedback and the best recommendation.

Why are we your best choice?

1. Better Price and cheaper carriage

As a factory, you can do business directly with us. It saves the profits of trading company. The price will be much better . And our plant is very closed to the seaport(15 km) and the airport(10km).

2. Better guarantee

We have the specialized department for the quality inspection during the whole processing.

3. Better after-service

We have our own professional sale and after-sale service team. We can supply the most professional service for you.

4. More Professional

With a powerful design team and more than 20 years of experience , We can manufacture machines according to the customer's practical demand or sample products .

5. Honesty and trustworthiness

We have exported the machines more than 10 years. And many customers place repeated orders from us.

Leave a message to know more about our machines

Ms. Linda Mobile: 0086- 13969620227