- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Fect

-

Voltage:

-

220v/380v

-

Dimension(L*W*H):

-

2900*1300*1450mm

-

Weight:

-

1700 kg

-

Name:

-

Automatic blank roll to roll sticker label die cutting machine

-

Function:

-

Automatic blank roll to roll sticker label die cutting machine

-

Keyword:

-

label die cutting machine

-

Control system:

-

PLC

-

Max. unwinding diameters:

-

550 mm

-

Cutting speed:

-

30-220 press/min

-

Cutting area:

-

300*350mm

-

Max. Feeding width:

-

320mm

-

Application:

-

paper film adhesive label, nylon membrane radium anti-fake trademark

-

Extended function:

-

laminating, hot stamping, punching

Quick Details

-

Type:

-

Die-cutting Machine

-

Production Capacity:

-

30-220 times/min

-

Max. workable width:

-

320mm

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Fect

-

Voltage:

-

220v/380v

-

Dimension(L*W*H):

-

2900*1300*1450mm

-

Weight:

-

1700 kg

-

Name:

-

Automatic blank roll to roll sticker label die cutting machine

-

Function:

-

Automatic blank roll to roll sticker label die cutting machine

-

Keyword:

-

label die cutting machine

-

Control system:

-

PLC

-

Max. unwinding diameters:

-

550 mm

-

Cutting speed:

-

30-220 press/min

-

Cutting area:

-

300*350mm

-

Max. Feeding width:

-

320mm

-

Application:

-

paper film adhesive label, nylon membrane radium anti-fake trademark

-

Extended function:

-

laminating, hot stamping, punching

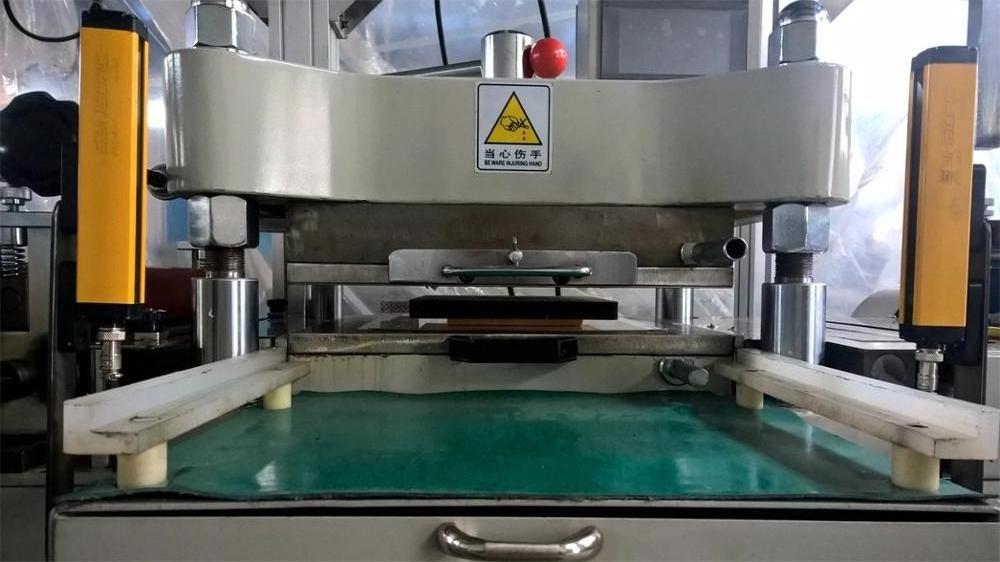

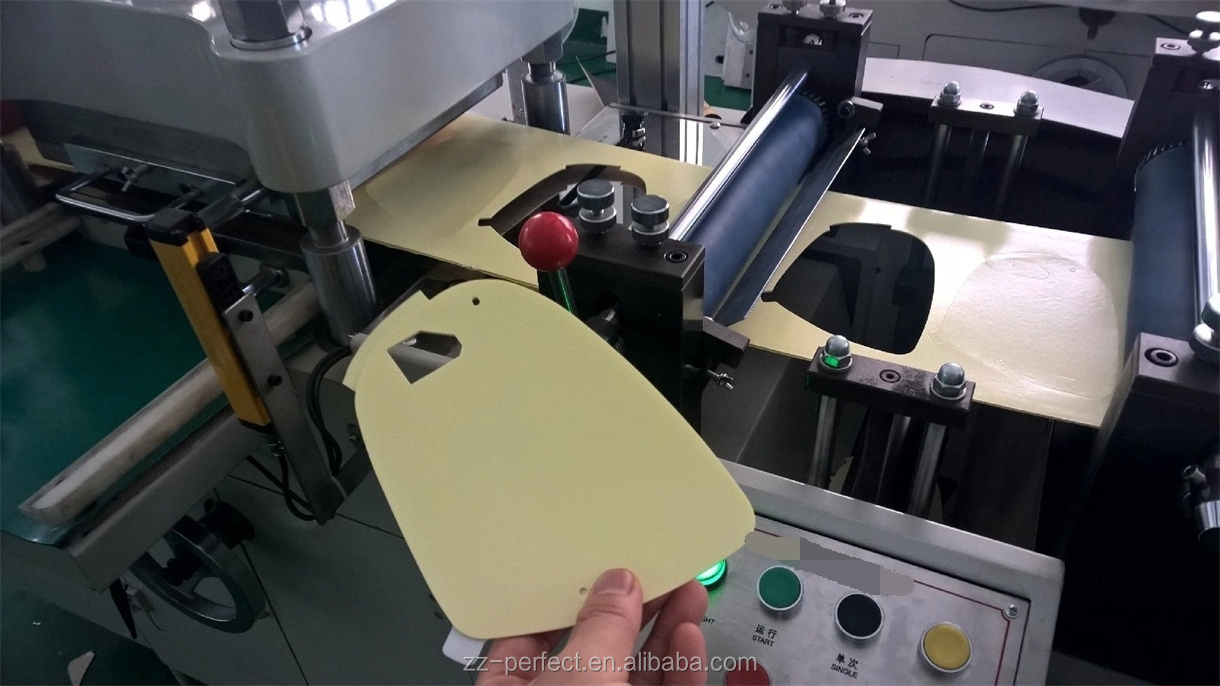

Automatic blank roll to roll sticker label die cutting machine

Standard functions : unwinding-die cutting-waste discharging-cutting into pieces-rewinding

Extended functions : laminating-stamping-punching

This machine is insistent of platen pressing structure, servo system control the material feeding and forwarding, the photoelectric eyes track the material, unwinding-die cutting-waste discharging-sheet cutting-rewinding all is completed in one turn, all are control by PLC control system.

♦Application♦

Automatic blank roll to roll sticker label die cutting machine is suitable for die cutting adhesive paper film label, nylon membrane trademark, radium anti-fake trademark, dacron label, laser hologram mark etc.

It is the copulate equipment for different printing machine and slitting machine, such as roll paper printing machine,flexo printing machine,screen printing machine, gravure printing machine. It's the most efficient machine for manufacturers in label printing, electronics and adhesive products industries.

♦Advantages♦

-

Suitability for larger and thicker materials

-

Sharper, crisper cuts

-

Minimal material deformation

-

Small order or short-run production

-

Decreased lead times for multiple parts

-

Lower tooling costs

- Easily convert material into custom shapes and designs

♦Technical Parameter♦

|

Model |

PF-350A |

PF-450A |

|

Cutting speed |

30-220 press/min |

30-200 press/min |

|

Max. Unwinding/rewinding diameter |

550mm |

550mm |

|

Max. feeding width |

320mm |

420mm |

|

Cutting area |

300*350mm |

400*450mm |

|

Positioning precision |

±0.1mm |

±0.1mm |

|

Total power |

2.2kw |

3kw |

|

Voltage |

220v±10% |

380v±10% |

|

Weight of machine |

1700kg |

1800kg |

|

Dimension |

2900x1300x1450mm |

3000x1400x1450mm |

♦Details♦

|

|

Also referred to as steel rule die cutting, automatic flat bed roll label die cutting press machine is a fabrication process which employs a flatbed die cutting press machine and steel rule dies to convert material into custom shapes and designs. The process is suitable for die cutting fabric, and a wide range of other materials, including paper, plastic, metal, rubber (including cutting neoprene), composites, and laminates, and creating uniform parts for a variety of manufacturing applications.

Compared to other die cutting machines—e.g., rotary die cutting machine and laser cutting machine—flatbed die cutting machine is more suitable for processing thicker material, producing larger parts, and completing small orders or short production runs. However, while flatbed die cutting machine demonstrates some advantages over rotary die cutting machine and laser cutting machine, some manufacturing applications are better suited to these other die cutting machines, such as high-precision, intricate design, or large run part production. The requirements and specifications demanded by a particular die cutting application—e.g., materials, sizing, tolerances, costs, turnaround times, etc.—help determine the type of die cutting process most suitable to use for it.

FQ320M slitting rewinding machine

Flexo label printing machine

| Package detail | Wooden case |

| Package size | 2900x1300x1500m |

| Gross weight | 1 7 00kg |