- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Rarlong

-

Warranty:

-

1 year

-

Product name:

-

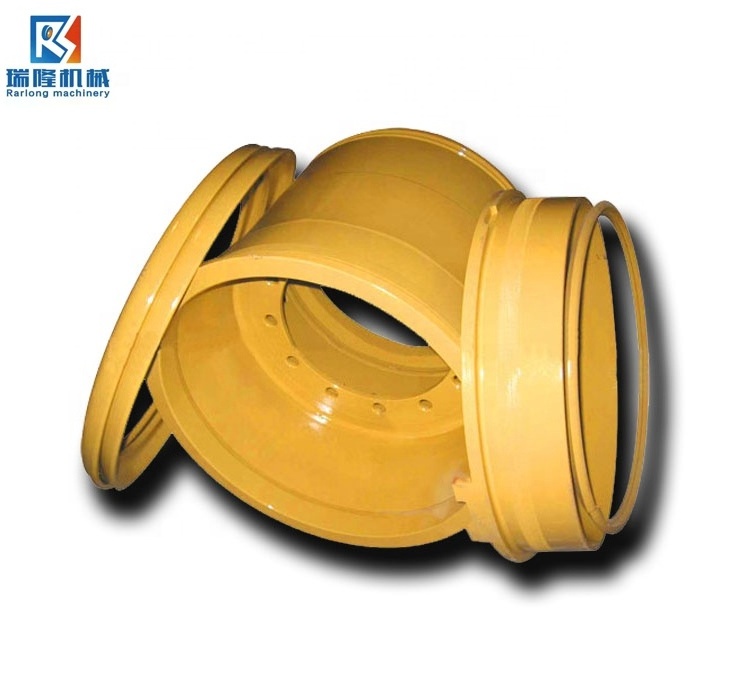

Golden rims Supplier carbon Steel wheel Rims 35 inch for Sale

-

Standard:

-

IATF6949/ISO9001/ISO14001/GB/T28001/GB/T19580

-

Welding feature:

-

Flash welding

-

Type:

-

Tubeless

-

Color:

-

Yellow or according to the customer's requirement

-

Raw material:

-

Q355/S355JR/ASTM grade50

-

Surface Treatment:

-

E-coating

-

Painting brand:

-

Valspar

-

Supply Ability:

-

10000 Set/Sets per Month

-

Certification:

-

ISO9001:2008

Quick Details

-

Finishing:

-

E-coating

-

Width:

-

8 inch-63 inch

-

Place of Origin:

-

Henan, China, Henan, China (Mainland)

-

Brand Name:

-

Rarlong

-

Warranty:

-

1 year

-

Product name:

-

Golden rims Supplier carbon Steel wheel Rims 35 inch for Sale

-

Standard:

-

IATF6949/ISO9001/ISO14001/GB/T28001/GB/T19580

-

Welding feature:

-

Flash welding

-

Type:

-

Tubeless

-

Color:

-

Yellow or according to the customer's requirement

-

Raw material:

-

Q355/S355JR/ASTM grade50

-

Surface Treatment:

-

E-coating

-

Painting brand:

-

Valspar

-

Supply Ability:

-

10000 Set/Sets per Month

-

Certification:

-

ISO9001:2008

Golden rims Supplier carbon Steel wheel Rims 35 inch for Sale

1. The steel parts are welded together, and the internal grain of the material is fine and dense, which ensures the strength and rigidity of the wheels.

2. Adopting the form of plug-in lap joint to ensure the coaxial and welding quality between the parts.

3. Lincoln welding equipment is adopted to ensure sufficient welding depth and strong welding penetration.Lincoln wire and flux to ensure weld strength and good appearance.

4. After welding, the whole shot blasting process can not only remove the oxide on the surface, but also eliminate the internal stress of the welding, so as to ensure the quality of the wheels.

2. All kinds of engineering machinery vehicle.

3. Rarlong's single-piece and multi-piece series' wheels for construction industries fully utilize high strength low alloy (HSLA) steel. Heat treated material is used for critical components of multi-piece wheels. Auto butt-welding is widely used on rim, ring and other circular parts; All circumferential weld seams are inspected by non-destructive inspection to ensure zero defect.

|

Size

|

TU/TL

|

Piece

|

Type

|

Recommend Tire

|

Application Vehicle

|

|

24-10/1.7(2.0)

|

TT

|

3

|

H

|

14.00-24

|

mining dumper

|

|

24-10/1.7(2.0)

|

TT

|

4

|

H

|

14.00-24

|

|

|

25-10.00/1.5

|

TL

|

3

|

N

|

14.00-25

|

backhoe loader/wheel dozer/earthmover/wheel loader

|

|

25-11.25/2.0

|

TL

|

5

|

N

|

16.00-25

|

wheel dozer/earthmover/wheel loader/port equipment

|

|

25-12.00/1.3

|

TL

|

3

|

N

|

15.50-25

|

|

|

25-13.00/2.5

|

TL

|

3

|

N

|

18.00-25

|

|

|

25-13.00/2.5

|

TL

|

5

|

H

|

18.00-25

|

|

|

25-14.00/1.5

|

TL

|

3

|

N

|

17.50-25

|

backhoe loader/wheel dozer/earthmover/wheel loader/wheel crane/scraper

|

|

25-15.00/3.0

|

TL

|

5

|

N

|

21.00-25

|

|

|

25-17.00/1.7

|

TL

|

3

|

N

|

20.5-25

|

|

|

25-17.00/2.0

|

TL

|

5

|

N

|

20.5-25

|

backhoe loader/wheel dozer/earthmover/wheel loader/wheel crane/scraper/articulated dump truckrigid truck

|

|

25-19.50/2.5

|

TL

|

3

|

N

|

23.5-25

|

|

|

25-19.50/2.5

|

TL

|

5

|

N

|

23.5-25

|

|

|

25-22.00/3.0

|

TL

|

3

|

N

|

26.5-25

|

|

|

25-22.00/3.0

|

TL

|

5

|

N

|

26.5-25

|

|

|

25-24.00/3.0

|

TL

|

5

|

N

|

30.0-25

|

|

|

25-25.00/3.5

|

TL

|

3

|

N

|

29.5-25

|

|

|

25-25.00/3.5

|

TL

|

5

|

N

|

29.5-25

|

|

|

25-30.00/1.5

|

TL

|

3

|

N

|

67x34.00-25

|

multi-purpose truck

|

|

25-36.00/1.5

|

TL

|

3

|

N

|

66x44.00-25

|

multi-purpose truck

|

|

29-17.00/3.5

|

TL

|

5

|

H

|

24.0-29

|

dump truck

|

|

29-22.00/3.0

|

TL

|

5pc

|

H

|

26.5-29

|

dump truck/wheel dozer/wheel loader

|

|

29-24.00/3.0

|

TL

|

5pc

|

H

|

29.5-29

|

|

|

29-25.00/3.5

|

TL

|

5pc

|

H

|

29.5-29

|

|

|

29-27.00/3.5

|

TL

|

5pc

|

H

|

32.0-29

|

|

|

33-13.00/2.5

|

TL

|

5pc

|

H

|

18.00-33

|

|

|

33-17.00/3.5

|

TL

|

5pc

|

H

|

24.00-33

|

|

|

33-22.00/4.0

|

TL

|

5pc

|

H

|

27.00-33

|

|

|

33-28.00/3.5

|

TL

|

5pc

|

H

|

35/65-33

|

|

|

35-15.00/3.0

|

TL

|

5pc

|

H

|

18.00-35

|

|

|

35-17.00/3.5

|

TL

|

5pc

|

H

|

21.00-35

|

|

|

35-27.00/3.5

|

TL

|

5pc

|

H

|

33.25-35

|

|

|

35-31.00/4.0

|

TL

|

5pc

|

H

|

37.25-35

|

|

|

39-28.00/4.0

|

TL

|

5pc

|

H

|

33.50-39

|

|

|

39-32.00/4.0

|

TL

|

5pc

|

H

|

40.00-39

|

|

|

45-36.00/4.5

|

TL

|

5pc

|

H

|

45.00-45

|

|

Q: Are you trading company or manufacturer ?

A: We are a factory with many production lines and various machines to fabricate steel wheel rims.Also, we have get the exporting license to devote ourselves into global markets.

Q:What about your product features?

A: Rarlong's single-piece and multi-piece series' wheels for construction industries fully utilize high strength low alloy (HSLA) steel. Heat treated material is used for critical components of multi-piece wheels. Auto butt-welding is widely used on rim, ring and other circular parts; All circumferential weld seams are inspected by non-destructive inspection to ensure zero defect.

RARLONG assures that all construction wheels are designed, manufactured, painted and tested to the highest standards in order to maximize the wheel performance, durability and value.

Q: How about quality control of your company?

A:

We pay great attention on quality control from the beginning to theend, keeping goods to meet the standard of IATF6949/ISO9001/ISO14001/GB/T28001/GB/T19580.