- Product Details

- {{item.text}}

Quick Details

-

Application:

-

separate the cement slurry from other fluids

-

Features:

-

rotating, non-rotating

-

Production Capacity:

-

10000pcs/month

-

Weight (KG):

-

1

-

Core Components:

-

rubber

-

size:

-

4 1/2''---20''

-

material:

-

Rubbers and Phenolic Resins.

-

plug type:

-

bottom plug, top plug

-

structure:

-

core, plug

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

DY On-Tech

-

Model Number:

-

All types

-

Application:

-

separate the cement slurry from other fluids

-

Features:

-

rotating, non-rotating

-

Production Capacity:

-

10000pcs/month

-

Weight (KG):

-

1

-

Core Components:

-

rubber

-

size:

-

4 1/2''---20''

-

material:

-

Rubbers and Phenolic Resins.

-

plug type:

-

bottom plug, top plug

-

structure:

-

core, plug

Oil Well Cement Solution bottom plug and top plug Cementing Rubber Plug

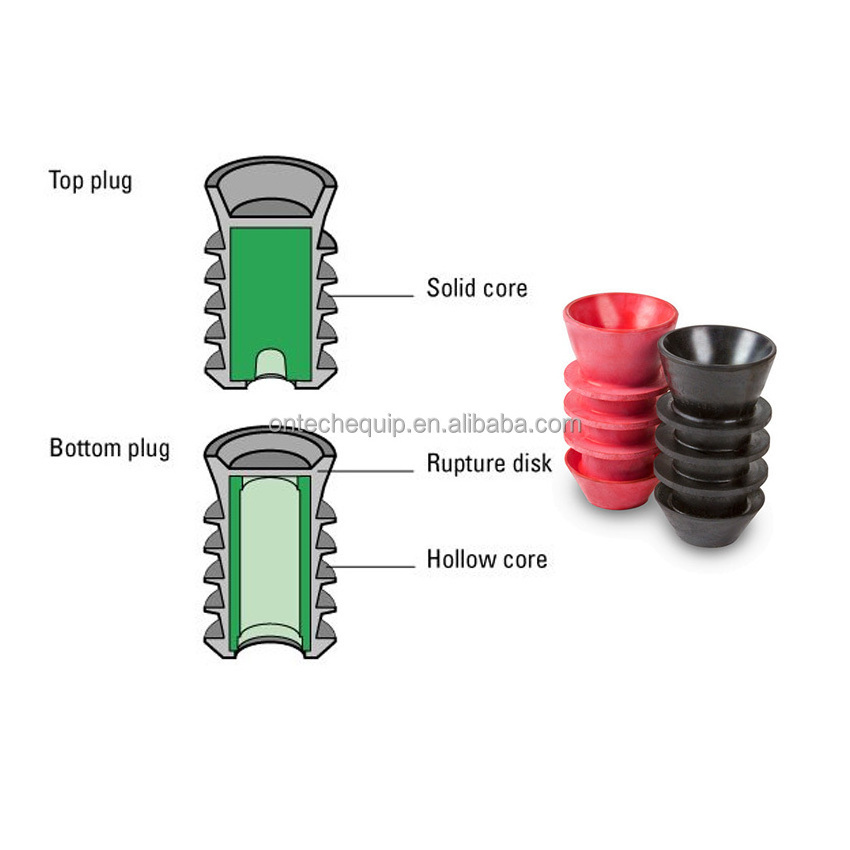

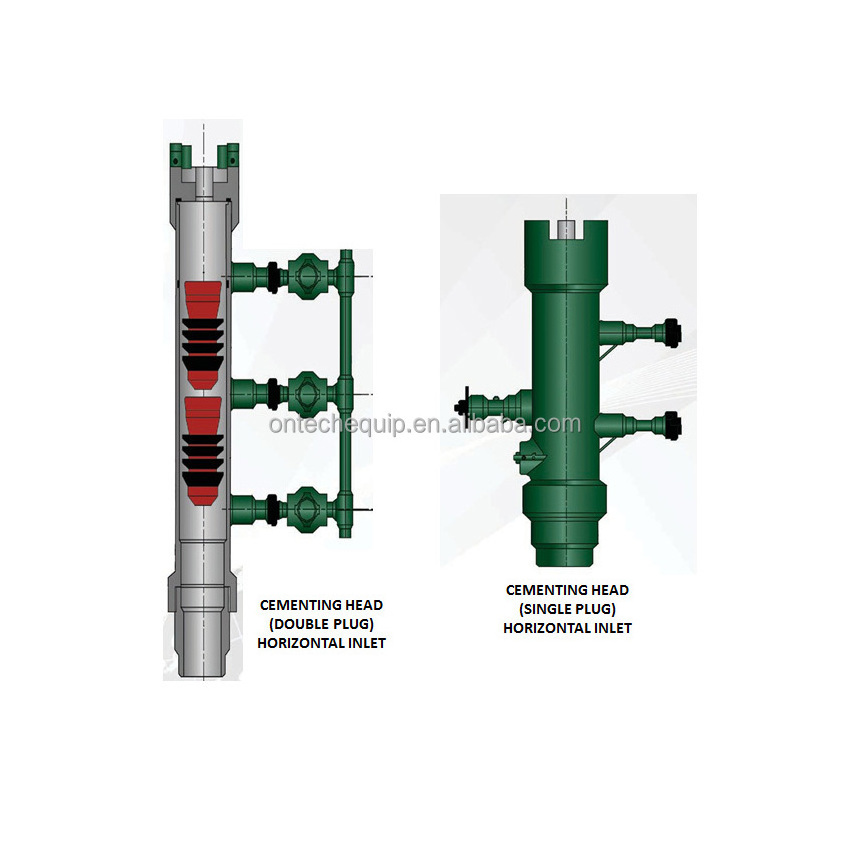

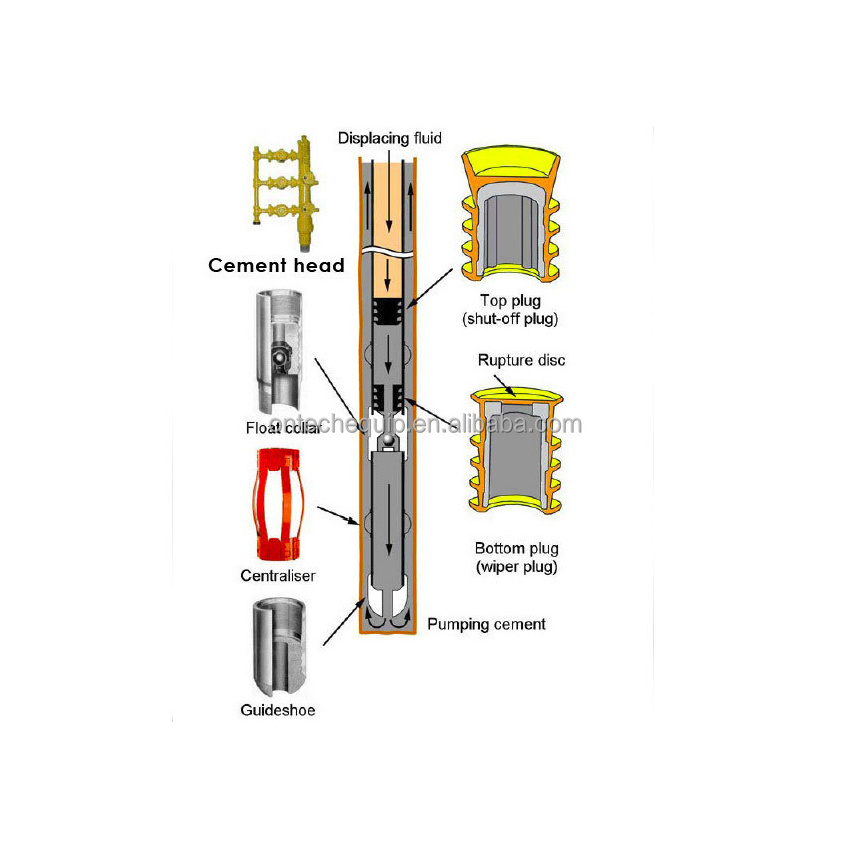

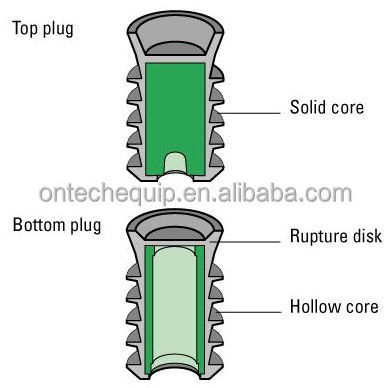

A rubber plug used to separate the cement slurry from other fluids, reducing contamination and maintaining predictable slurry performance. Two types of cementing plug are typically used on a cementing operation. The bottom plug is launched ahead of the cement slurry to minimize contamination by fluids inside the casing prior to cementing. A diaphragm in the plug body ruptures to allow the cement slurry to pass through after the plug reaches the landing collar. The top plug has a solid body that provides positive indication of contact with the landing collar and bottom plug through an increase in pump pressure.

1) Types Available: Conventional standard plugs and non-rotating plugs are available;

2) Standard: API

3) API and ISO certified

4) Specifications: 4 1/2''---20''. More special sizes or combination are available as requested.

5) Material: Rubbers and Phenolic Resins.

6) Application

Our cementing plugs are specially designed with a positive wiping action to ensure that the casing is clean.

The top cementing plugs is designed to exert continous pressure on the casing wall.

The fins and tail section of bottom plugs provide positive wiping action. Fins also serve as a seal while cementing.

7) Structure:

The core is made of aluminum or phenolic resins, depending on the application and well conditions.

The plug is made of high performance materials such as rubbers or phenolic resins.

8) Using Method:

Place bottom plug before injecting cement, and pump the scrape to clean the well-wall. After all is set, build the pressure of 2-4MPa till the rubber diaphragm is broken, and thus circulation is formed. Then inject the cement, place the top plug, pump, set the pressure, and well cementation comes to an end.

| Casing size(in) | Casing weight range | Wiper Fin O.D | ||

| mm | in | mm | in | |

| 4 1/2" | 14.14-17.26 | 9.50-11.60 | 110 | 4.331 |

| 5" | 17.11-35.86 | 11.50-24.10 | 122 | 4.803 |

| 5 1/2" | 20.83-39.88 | 14.00-26.80 | 135 | 5.315 |

| 7" | 25.30-56.55 | 17.00-38.00 | 170 | 6.693 |

| 7 5/8" | 35.72-63.69 | 24.00-42.00 | 185 | 7.283 |

| 9 5/8" | 53.57-79.62 | 36.00-53.50 | 235 | 9.252 |

| 10 3/4" | 60.27-97.77 | 40.50-65.70 | 260 | 10.236 |

| 13 3/8" | 71.43-107.15 | 48.00-72.00 | 333 | 13.11 |

| 20" | 139.89-197.93 | 94.00-133.00 | 498 | 19.606 |