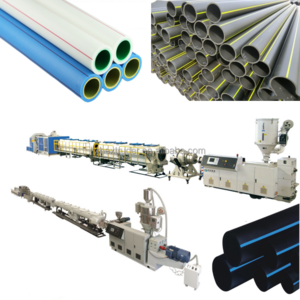

Raw Material: Pellets/granule

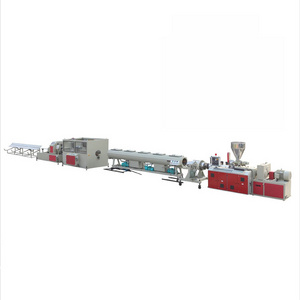

This line is consist of two or one single screw extruder, extrusion mould, three roller calander, roller temperature controller,

cooling stacker with edge cutting device, haul-off machine,cutting machine, collection platform. etc/

Plastic Sheet has characters of high strength and corrosion protection, with some padding can achieve enhance, toughen, flame

retardant, anti-static electricity function, sheet surface can be embossed and polished, mainly used on producing plate, bowl,

saucer, box, disposable plastic cup and so on hot forming products, also can be used on packing of food, vegetable, fruit, drinks,

dairy, industrial parts and so on field like stationary sheet, printing sheet and so on.

retardant, anti-static electricity function, sheet surface can be embossed and polished, mainly used on producing plate, bowl,

saucer, box, disposable plastic cup and so on hot forming products, also can be used on packing of food, vegetable, fruit, drinks,

dairy, industrial parts and so on field like stationary sheet, printing sheet and so on.