- Product Details

- {{item.text}}

Quick Details

-

transformation type:

-

wheat/maize/rice

-

extraction:

-

70-80%

-

system:

-

PLC system

-

style:

-

pneumatic or electric

-

Certification:

-

ISO 9001

Quick Details

-

Place of Origin:

-

Hebei, China

-

After-sales Service Provided:

-

Field installation, commissioning and training, Engineers available to service machinery overseas

-

quality:

-

european standard

-

transformation type:

-

wheat/maize/rice

-

extraction:

-

70-80%

-

system:

-

PLC system

-

style:

-

pneumatic or electric

-

Certification:

-

ISO 9001

Hebei Africa Machinery CO.,LTD

We are a professional manufacturer of wheat flour milling and corn flour milling complete-set machineries. We have been in this field for many years and we are a leader.

We can supply 40-2,400T/24H wheat flour milling machineries and 30-600T/24H corn flour milling machineries. Our equipments run smoothly and steadily, with low noise and zero pollution. The service life can reach 25 years. We have installed many projects in the whole world.

The process of flour milling (from wheat to milled into wheat flour) usually consist of the following:

1. wheat storage (silos, or warehouse) ---------- 2. cleaning system (sifter, destoner, seprater, magnet, scourer, etc) ----------- 3. dampening (dampener, conditioning silos, etc) ---------- 4. milling system (roller mill, plansifter, purifier, impact detacher, etc.) ---------- 5. Flour pressure and blending system (if need) ---------- 6. flour packing and stacking

Photo of machines

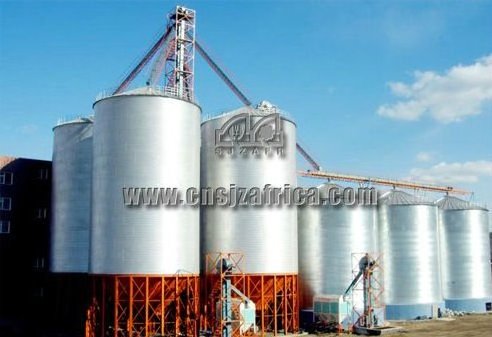

silos

We store wheat in silos. There are temperature detectors inside of silos. If the temperature inside is very high, the blower can blow air into silos to reduce the temperature to protect the grains.

cleaning system

There are many kinds of cleaning machines. They can be used to remove stones, seed of grass, ropes, clods, straws etc to keep flour clean.

dampening system

Before being milled, the wheat should be dampened. That will help the milling. The bran will be easily separated from endosperm without damage.

milling system

Roller mills break the material.

Plansifter separates the suitable size flour.

Purifier will extract the pure flour, semolina, etc.

blending system

The blending system can mix different flour and guarantee the stability of quality.

flour packaging

we have automatic packing machines which can pack flour in 2-50 kg/bag.

PLC system: fully automatic controlling system with a lot of balancer, sensor, etc.

Automatically display raw wheat, clean wheat, flour, bran instant flowing quantity, flowing percentage, and a percentage for a fixed time.

With working history checking system.

With fault alarm system.

With printer.