- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

13000*1200*1500

-

Weight:

-

1500 KG

-

Place of Origin:

-

Henan, China

-

Voltage:

-

380V,50HZ, 3 phase

-

Item:

-

Tomato paste production line

-

Raw material:

-

Tomato

-

Processing Types:

-

Industrial tomato processing line

-

Final product:

-

Tomato paste ,tomato ketchup,tomato sauce,tomato puree

-

Capacity:

-

1T-20T

-

Suitable for:

-

Snack Food Processing Plant

-

Package:

-

Aspetic filling,can filling,bottle filling,jar filling etc

-

Application:

-

Food Industry

-

Machine Material:

-

Food Grade Stainless Steel 304

-

Heating source:

-

Steam+electricity

Quick Details

-

Machinery Capacity:

-

1T-20T

-

Brand Name:

-

ZYL

-

Year:

-

2023

-

Dimension(L*W*H):

-

13000*1200*1500

-

Weight:

-

1500 KG

-

Place of Origin:

-

Henan, China

-

Voltage:

-

380V,50HZ, 3 phase

-

Item:

-

Tomato paste production line

-

Raw material:

-

Tomato

-

Processing Types:

-

Industrial tomato processing line

-

Final product:

-

Tomato paste ,tomato ketchup,tomato sauce,tomato puree

-

Capacity:

-

1T-20T

-

Suitable for:

-

Snack Food Processing Plant

-

Package:

-

Aspetic filling,can filling,bottle filling,jar filling etc

-

Application:

-

Food Industry

-

Machine Material:

-

Food Grade Stainless Steel 304

-

Heating source:

-

Steam+electricity

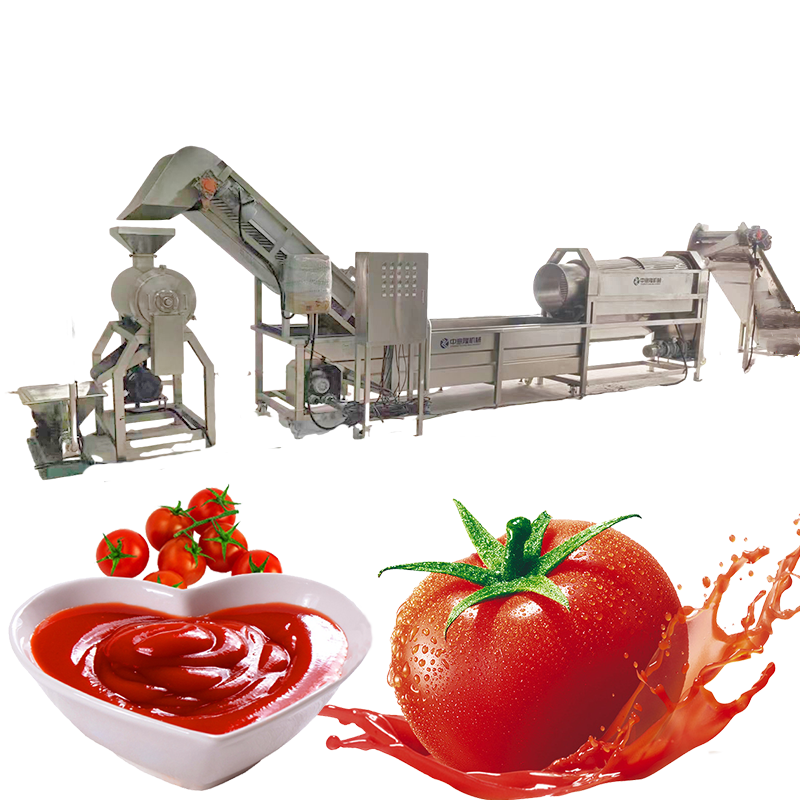

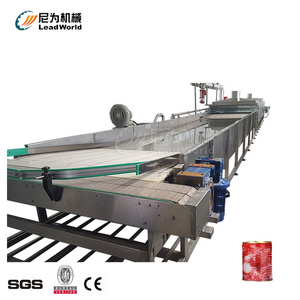

Industrial Automatic Tomato Sauce Ketchup Making Machine Grinding Tomato Paste Production Line

Henan zhongyilong machine a professional tomato processing machine manufacturer and exporter in China.which can provide turnkey solution and technology for tomato processing line.

Introduction of tomato processing line:

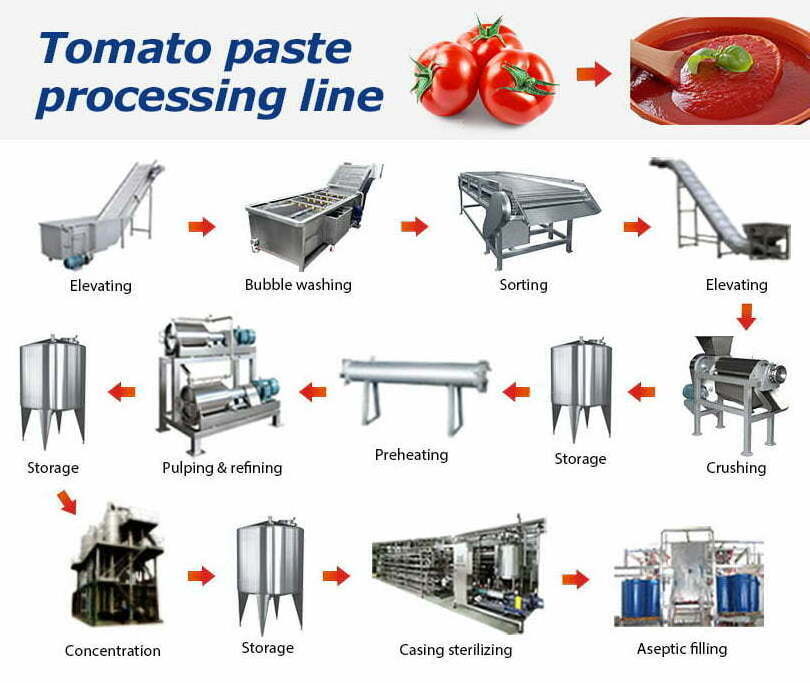

Tomatoes are usually processed for paste and the processing line mainly includes five parts: fresh tomato receiving, pre-washing and sorting section; extracting section; concentrating section; pasteurizing or sterilizing section; aseptic filling section. It is mainly composed of discharge system, hydraulic convey system, bucket elevating, washing and sorting system, crushing system,pre-heating system, pulping and refining system, evaporating& concentrating system, sterilizing system, aseptic filling system.Tomato paste in aseptic drum can be further processed to ketchup, sauces, juices in tin can/bottle/pouch, etc.

Introduction of tomato processing line:

Tomatoes are usually processed for paste and the processing line mainly includes five parts: fresh tomato receiving, pre-washing and sorting section; extracting section; concentrating section; pasteurizing or sterilizing section; aseptic filling section. It is mainly composed of discharge system, hydraulic convey system, bucket elevating, washing and sorting system, crushing system,pre-heating system, pulping and refining system, evaporating& concentrating system, sterilizing system, aseptic filling system.Tomato paste in aseptic drum can be further processed to ketchup, sauces, juices in tin can/bottle/pouch, etc.

Product details

Tomato processing line can produce from fresh tomato to different kinds of final product. The most popular is tomato paste processing line, produce from fresh tomato to tomato paste with aseptic bag in drum. That mainly includes: fresh tomato receiving system, washing system, sorting system, extracting system, concentrating system, sterilizing system, and aseptic filling system.

tomato paste with aseptic bag in drum. And the tomato paste in aseptic bag in drum can be further produced to tomato ketchup, sauces, juice and filled in sachet, stand-up pouch, metal can, PP container, bottle, gable top, etc.

The production process of making tomato paste:

Fresh/mature tomato -1. Tomato washing - 2.Sorting -3.Tomato crushing - 4.Tomato pulping - 5.Vacuum concentration - 6.Paste sterilization - 7.Filling.

Fresh/mature tomato -1. Tomato washing - 2.Sorting -3.Tomato crushing - 4.Tomato pulping - 5.Vacuum concentration - 6.Paste sterilization - 7.Filling.

Product Description

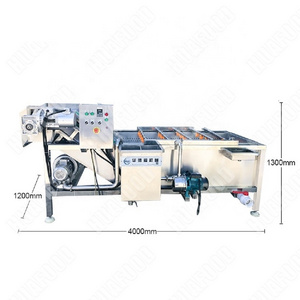

1.Tomato washing machine

The tomato washing machine

Use of a bubble rolling, brushing, spraying technology to maximize cleaning of objects.

is used for washing

the soil and leaves of tomatoes

thoroughly.

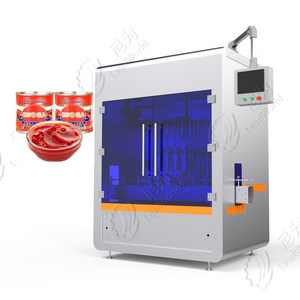

5. tomato ketchup filling machines

special for sauce, jam, oil, and other viscous products filling, capping and equipped with rotary transmission, PLC and frequency adjuster in speed. It is innovated and designed in the requirement of edible oil and paste technics, on the bases of introducing, digesting and absorbing advanced technology. It is reasonable in structure, safe to operate and easy to maintain, which is an ideal choice for viscous products.

Tomato Paste Packing Machine

According to the packing requirements, the automatic whole line can ensure that the packaged products fall into the carton

through the positioning device. The machine adopts PLC+touch display control, and is equipped with a bottle shortage alarm device to protect the safety of no bottles without packing.

application

|

Tomato end products

|

Tomato juice

|

Jar filling

|

|

|

|

Tomato puree

|

|

PET bottle filling

|

|

|

Tomato paste

|

|

Glass bottle filling

|

|

|

Tomato sauce

|

|

Can filling

|

|

|

Tomato ketchup

|

|

Bareel filling

|

|

|

Tomato powder

|

|

Sachet filling

|

Related products

Why choose us

Thanks for your inquiry on Alibaba. ZHONGYILONG Machienry co.,ltd have been specializing in food&beverage processing line for over 40 years and successfully set up 300 factories for demestic and international customers.

we are a high-tech manufacturing enterprise focusing on automatic packaging production equipment for food, beverage, and electronic products. We can customize beverage production line process and formula according to customer's demand.

Our business scope covers dairy products, carbonated beverages, wine, beer, fermented beverages tomato paste, porridge, mixed juice drinks, vitamin functional drinks, pure water.cooking oil production lines, etc.

We provide one-stop service to help customers build food and beverage plants: process formula, plant guidance equipment selection, installation and commissioning, technical training, after-sales service.

We look forward to your inquiry and exchange cooperation.

To generally understand your requirement and facilitate our further communication, we'd like to know from you:

1.Will this be your own business or you are trading company?

2.what will be the scale of this project: home-scale ,commerical-scale or government procurement?

3.By which process: you already have process flowchart or we design for you?

4.what's the final products?

package and product specification detail

5.what's the estimated capacity?

input of raw material or output of final products, how much, by hour/daily or annual?

6.What's stage of this project are you in?

gathering information for future inspection or want to finish this project in half or one year?

Please kindly understand that we will work very closely with you to offer an turn key solution.So firstly we should fully comprehend your situation in order to make out a reasonable project scheme with affordable cost.

Looking forward to your early response.

FAQ

Hot Searches