- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

Glass Removal Equipment

-

Power:

-

40KW

-

Material:

-

Wooden box

-

Marketing Type:

-

New Product 2023

-

Weight (KG):

-

3000 kg

-

product name:

-

Photovoltaic Panel Glass Removal Machine

-

Raw material:

-

Waste Solar Panels

-

Function:

-

Waste Solar Panels Recycle

-

Color:

-

Customized Color

-

Usage:

-

Recycling Waste Solar Panels

-

Final productglass:

-

Glass

-

Voltage:

-

220-380V

-

Dimension:

-

500*200*200cm

-

Keywords:

-

Solar Panels Recycling Plant Solar Chip Recycling Equipment

-

Advantage:

-

High degree of automation, time-saving and labor-saving

Quick Details

-

Production Capacity:

-

1 times/min

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

DUNPAI

-

Model Number:

-

Glass Removal Equipment

-

Power:

-

40KW

-

Material:

-

Wooden box

-

Marketing Type:

-

New Product 2023

-

Weight (KG):

-

3000 kg

-

product name:

-

Photovoltaic Panel Glass Removal Machine

-

Raw material:

-

Waste Solar Panels

-

Function:

-

Waste Solar Panels Recycle

-

Color:

-

Customized Color

-

Usage:

-

Recycling Waste Solar Panels

-

Final productglass:

-

Glass

-

Voltage:

-

220-380V

-

Dimension:

-

500*200*200cm

-

Keywords:

-

Solar Panels Recycling Plant Solar Chip Recycling Equipment

-

Advantage:

-

High degree of automation, time-saving and labor-saving

Products Description

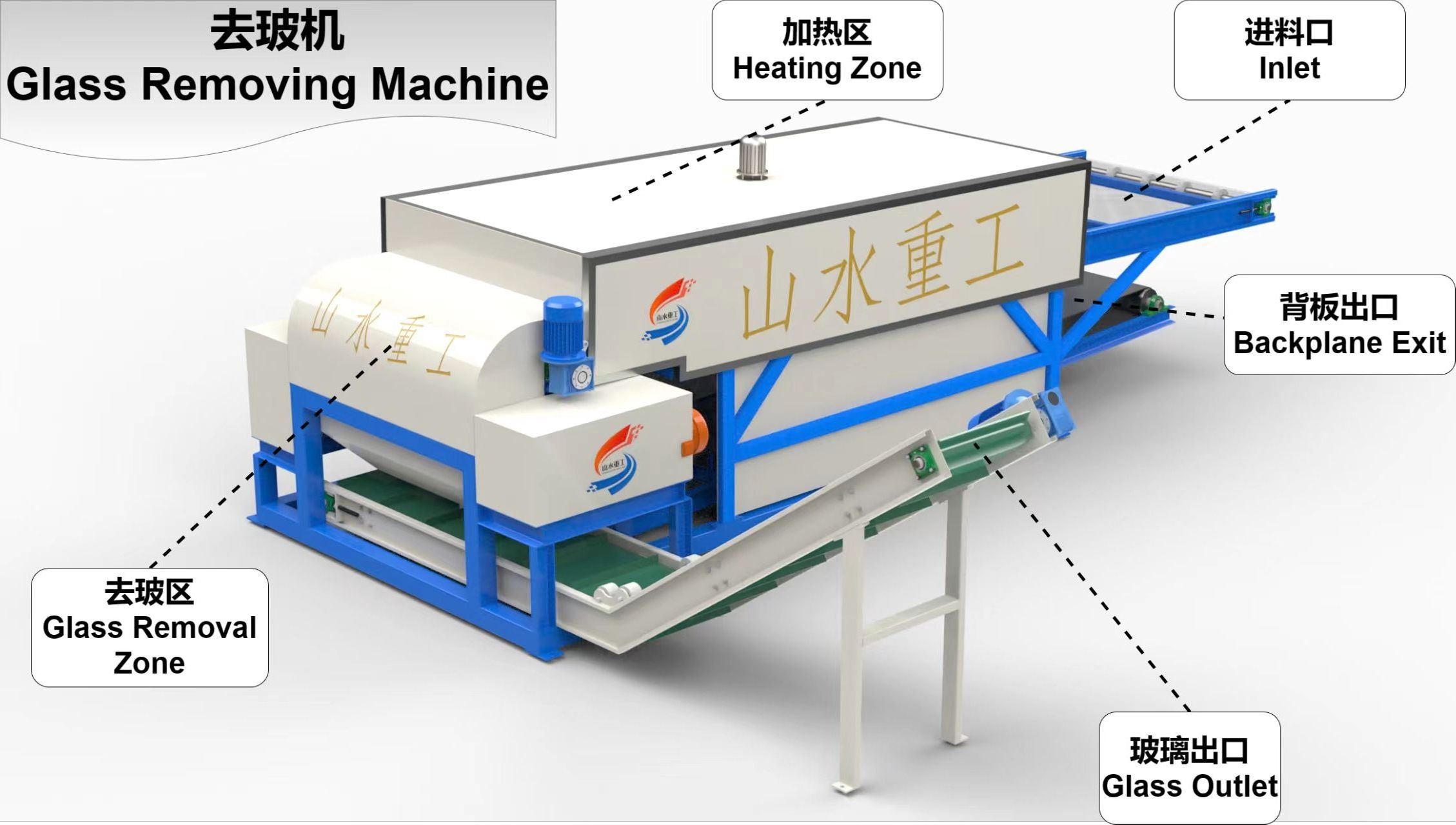

Photovoltaic panel glass separation machine is a device specifically designed for processing waste photovoltaic panels, specifically for single crystal silicon and polycrystalline silicon single glass panels. This equipment adopts automation technology to achieve automatic feeding, discharging, and separation of finished glass and panels, improving production efficiency and reducing labor costs.

Product Details

During the operation of the photovoltaic panel glass separation machine, waste photovoltaic panels are placed at the entrance of

the equipment and fed into the machine through an automatic feeding system. Next, the milling cutter inside the machine began to

work, milling off the glass on the surface of the photovoltaic panel and separating the panel from the glass. This process is

equipped with environmental protection facilities to ensure that no dust pollution is generated during the production process. The

automatic discharge system outputs the processed glass and panel separately, completing the entire processing process.

Specification

Compared to traditional manual processing methods, photovoltaic panel glass separation machines have significant advantages.

Firstly, it can quickly and accurately separate glass from panels, improving production efficiency and reducing labor costs.

Secondly, the equipment adopts a closed production process to ensure environmental protection and safety during the production

process. The application range of photovoltaic panel glass separation machine is wide, suitable for the treatment of various types

of waste photovoltaic panels, with market prospects and application value.

|

Photovoltaic Panel Glass Removal Machine

|

|

|

|

Product Name

|

Photovoltaic panel glass removal machine

|

|

|

Power

|

40 kw

|

|

|

Voltage

|

220-380V

|

|

|

Overall Size

|

500*200*200cm

|

|

|

Total Weight

|

3000KG

|

|

|

Design Times

|

1 times/min

|

|

|

Control Method

|

Fully automatic

|

|

Applications

Finished product display

Hot Searches