- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

110v/220v

-

Power:

-

2500w

-

Weight:

-

85 KG

-

Dimension(L*W*H):

-

70*58*62cm

-

Year:

-

2023

-

Application:

-

Food Processing Machine

-

Name:

-

Candy Making Machine

-

Product name:

-

Tabletop Gummy Machine

-

Function:

-

Multifunctional Candy Machines

-

Keywords:

-

Easy Operate High Productivity

-

Final product:

-

Candy

-

Usage:

-

Food Industry Equipment

-

Suitable for:

-

Snack Food Processing Plant

-

Material:

-

304/316 Stainless Steel

-

Advantage:

-

Easy Operation High Efficiency

Quick Details

-

Marketing Type:

-

New Product 2023

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

XINYU

-

Voltage:

-

110v/220v

-

Power:

-

2500w

-

Weight:

-

85 KG

-

Dimension(L*W*H):

-

70*58*62cm

-

Year:

-

2023

-

Application:

-

Food Processing Machine

-

Name:

-

Candy Making Machine

-

Product name:

-

Tabletop Gummy Machine

-

Function:

-

Multifunctional Candy Machines

-

Keywords:

-

Easy Operate High Productivity

-

Final product:

-

Candy

-

Usage:

-

Food Industry Equipment

-

Suitable for:

-

Snack Food Processing Plant

-

Material:

-

304/316 Stainless Steel

-

Advantage:

-

Easy Operation High Efficiency

https://lhgtmachine.en.alibaba.com/

https://lhgtmachine.en.alibaba.com/

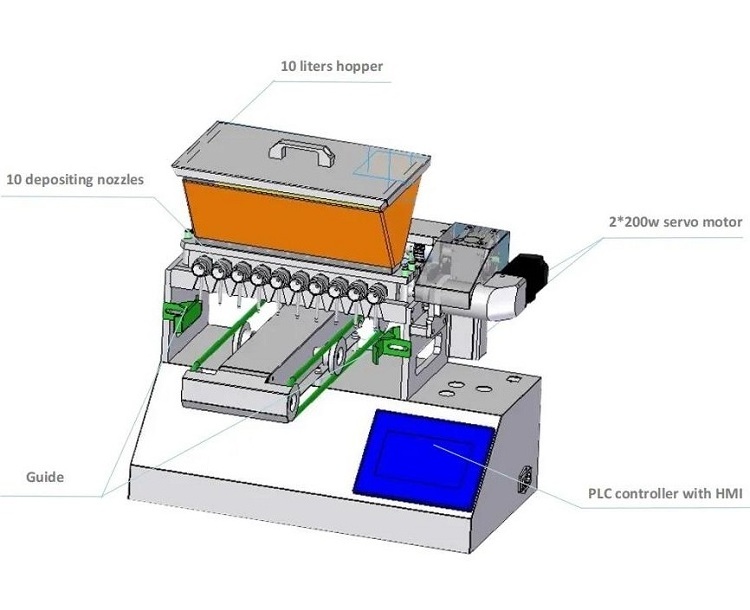

| Machine material | stainless steel 304 |

| Depositing production capacity | 15 - 20 cycle/min |

| Depositing capacity | 1 -7 g/shot Configuration 10 filling nozzle |

| Power supply | 3kw, AC220V, 50Hz, single phase power |

| Machine size | 70cm * 58cm * 62cm |

| Machine weight | 75kg |

Features

1. Flexible and diverse production capacity: It can produce candies of various shapes and sizes, such as hard candies, gumm y , lollipops, etc.

2. High degree of automation: it can automatically complete the mixing, heating, forming, cooling and other technological steps of syrup, reducing labor intensity and improving production efficiency.

3. High precision control system: precise pouring of syrup can be realized to ensure the same weight and shape of each candy.

4. Easy to clean and maintain: the machine structure is simple, easy to disassemble and clean, and has a reliable maintenance system.

5. High safety: food grade materials and design in line with health standards are adopted to ensure safe and harmless products.

Product Introduction

The candy pouring machine produced by our company is a device specially designed to produce candy of all shapes and sizes. It is mainly composed of barrel, heating system, control system, forming mold and so on. When in use, the required raw materials (such as sugar, syrup, flavor, color, etc.) into the material bucket, and through the heating system for mixing, heating, etc. The syrup is then channelled through a pipe into a molding mold, where it is poured and cooled according to the desired shape of the candy to form the final candy. The candy pouring machine can produce not only traditional hard candies and gumm y , but also various types of candies such as lollipops, gum and bonbons.

FAQ

1.How to find a solution suitable for my product? Tell me about your product details:

1. What kind of product you have.

2. the size of your product.

2.How easy is it to operate packaging equipment?

The good news is that as long as your packaging system isn't hyper-customized, the equipment is pretty easy to use! Most of our equipment does not require advanced technical knowledge to operate.

3.How much does packaging equipment cost?

There is no quick, easy answer to this question. Packaging machinery is specific to the customer, so arriving at 'standard pricing' isn't usually practical. Pricing largely depends upon your unique needs, such as the products you want to package, the speeds you would like to achieve, your sizes or the complexity of your process.

4.Which machines are available in-stock?

If your needs are fairly standard and straightforward, you may be able to snag an In-Stock Machine and get it delivered in just a few weeks! CALL US to ask about our current inventory.

5.What is your after sales services?

After finish the production, we will debug the production line, take photos, videos and send them to customers via mail or instant tools.

After the commissioning, we will package the equipment by standard export package for shipment.

According to the customer's request, we can arrange our engineers to customers' factory to do the

installation and training.

Engineers, sales managers and after-sales service manager will form a after-sales team, online and off line, to follow the customers' project.