- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

1

-

Product name:

-

silicone rubber

-

Application:

-

centrifugal casting

-

Keyword:

-

silicone rubber mold

-

applicable metal:

-

zinc, lead, tin

-

appearance:

-

gule, disc

-

curing time:

-

60 minutes

-

diameter:

-

20" max

-

Packing Details:

-

paper box

-

Sample Time:

-

2~5 Days

-

Color:

-

purple, blue, green, yellow

Quick Details

-

Place of Origin:

-

China

-

Machine Type:

-

mold casting

-

Core Components:

-

silicon rubber

-

Weight (KG):

-

1

-

Product name:

-

silicone rubber

-

Application:

-

centrifugal casting

-

Keyword:

-

silicone rubber mold

-

applicable metal:

-

zinc, lead, tin

-

appearance:

-

gule, disc

-

curing time:

-

60 minutes

-

diameter:

-

20" max

-

Packing Details:

-

paper box

-

Sample Time:

-

2~5 Days

-

Color:

-

purple, blue, green, yellow

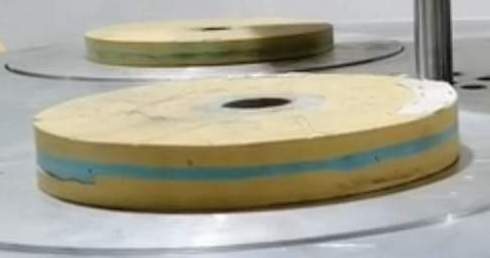

A wide range of specially formulated silicone rubbers to meet different demands for spin casting of low-melt zinc alloy and tin-lead alloy.

And Available in disc diameter: 8", 9”, 12”, 14”, 16”, 18”, 20”, 25”;

thickness: 5mm-10mm.

|

Available Disc diameter |

Available Disc Thickness |

Remark |

|

|

6 inch |

14 inch |

Customized from 3mm -10mm. |

Other sizes also available upon requested. |

|

8 inch |

16 inch |

||

|

9 inch |

18 inch |

||

|

10 inch |

20 inch |

||

|

12 inch |

25 inch |

||

|

|

PA |

GA |

BA |

YB |

|

Color |

purple |

Green |

Blue |

Yellow |

|

|

|

|

|

|

|

Vulcanizing Temperature |

165 °C |

150-165 °C |

165 °C |

Specially developed cheaper silicon rubber, mainly used to reduce cost, half or 2/3 thick of the mold, not directly contact alloy.

|

|

Vulcanizing time |

60mins |

|

|

|

|

Shore Hardness after vulcanizing |

75 |

65 |

70 |

|

|

Tear-resistant strength |

98Mpa |

80Mpa |

95Mpa |

|

|

Elongation |

32% |

58% |

72% |

|

|

Highest heat-resistance (10 secs |

750 °C |

500 °C |

500 °C |

|

|

Applicable alloy |

Zinc,Zamak |

Tin, lead, flat parts

|

Tin, lead, miniature figurines, photo frame etc.

|