- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

BDX-PIPE BENDER MACHINE

-

Power (kW):

-

45

-

Weight (KG):

-

45

-

Power:

-

Hydraulic

-

Machine Type:

-

Beading Machine

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Field installation, commissioning and training, Online support, Video technical support

-

Name:

-

pvc hdpe pipe bander machine

-

Type:

-

Hydraulic pipe Bending Tools machine

-

Color:

-

Customer Requirement

-

Voltage:

-

380V or customized

-

Keyword:

-

hdpe pipe bending bender machine

-

Control system:

-

PLC fully automatic

-

Bending diamter:

-

10~250mm

-

Certification:

-

ISO 9001:2000

-

After Warranty Service:

-

Video technical support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

Argentina, Algeria, Kazakhstan

Quick Details

-

Max. Bending Angle (Deg):

-

90

-

Bending Precision (Deg):

-

99

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

BDX-PIPE BENDER MACHINE

-

Power (kW):

-

45

-

Weight (KG):

-

45

-

Power:

-

Hydraulic

-

Machine Type:

-

Beading Machine

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Field installation, commissioning and training, Online support, Video technical support

-

Name:

-

pvc hdpe pipe bander machine

-

Type:

-

Hydraulic pipe Bending Tools machine

-

Color:

-

Customer Requirement

-

Voltage:

-

380V or customized

-

Keyword:

-

hdpe pipe bending bender machine

-

Control system:

-

PLC fully automatic

-

Bending diamter:

-

10~250mm

-

Certification:

-

ISO 9001:2000

-

After Warranty Service:

-

Video technical support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

Argentina, Algeria, Kazakhstan

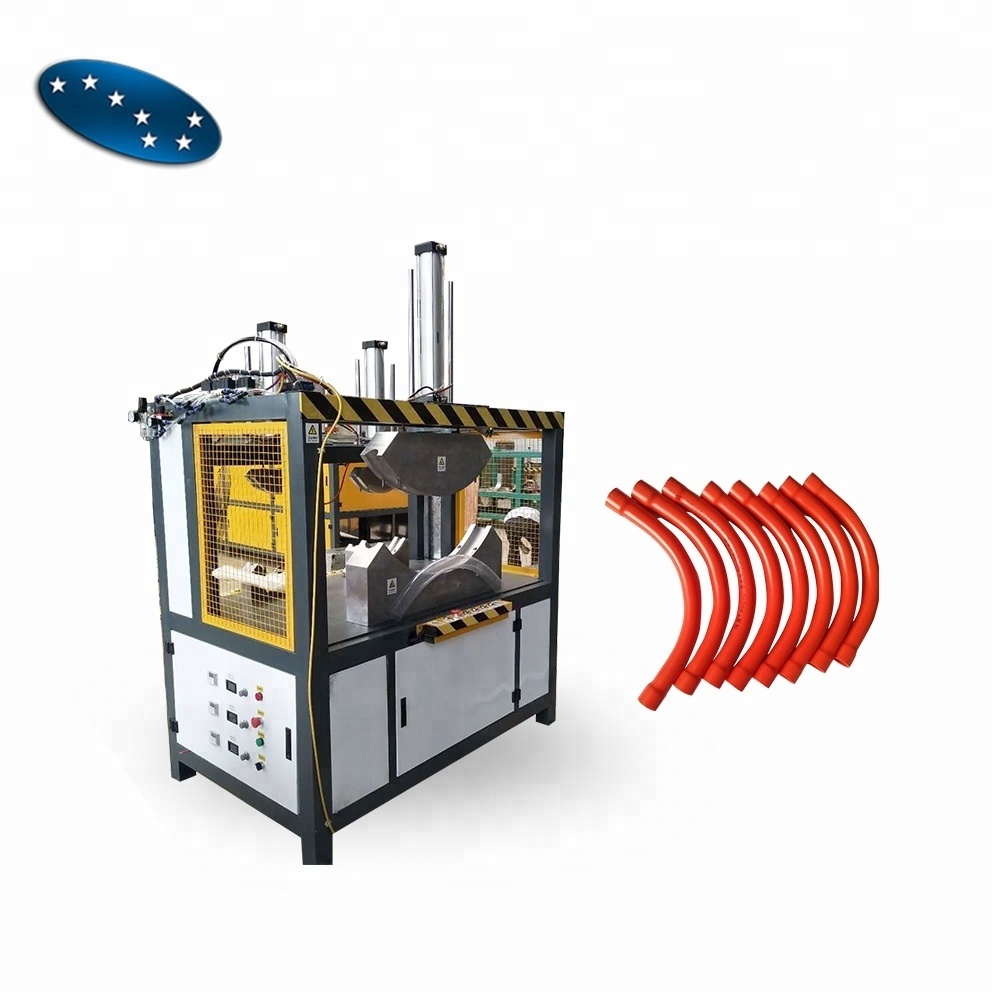

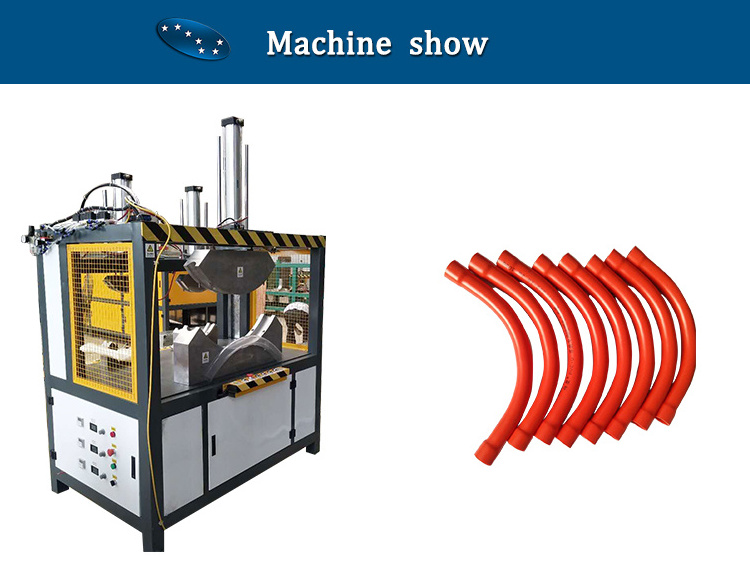

Machine description of HDPE pipe dending manual machine :

1. Our special Japan technologe energy-saving insulation equipment compared with other suppliers can improve the heat utilization rate of 40% above.

2. Domestic initiative--infrared barium plated vacuum heating machine, it can provide absolute equal temperature, at the same time ,it can upward heat energy radiation which can save heat energy 40 percent better than general machines.

3. Our company's special multi-functional positioning by the foot, so that bending angle uniform.

4. HDPE pipe dending manual machine can make the material heated evenly. The heating temperature is adjustable, less electricity

5. Simple ways of operation: don’t need professional workers.

6. Equipment table for the thickening of steel plate can ensure that the HDPE pipe dending manual machine production process will not be deformed, so the product can have better effect.

7. Pneumatic strut of model can locate materials exactly and efficiently. Pneumatic pressure control system is stable and durable.

8. Equipment is designed with double button switch, the workers can operate safely, automatic mold to promote, timing out of the filler, the timing of blowing cooling, cooling stereotypes after the mold automatically lift, cycle operation.

9. The machine has double anti-leakage protection function.

10. The rack of machine is high-duty and it works very stably, it’s convenient to be transported and installed.

11. The design of our products is neoteric and artistic. Our machine’s surface is oil painted, so it can always maintain fire-new.

12. Function of temperature adjust. It can adjust the temperature of electro-heat equipment according to the material’s type, thickness and texture, so it can improve the processing quality of the machine.

13. Function of timing. It can set up the working time of electro-heat equipment according to the material’s type, thickness and texture, so it can improve the processing quality of the machine and reduce the requirement of technology .

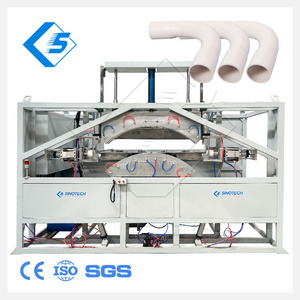

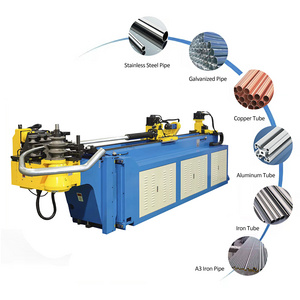

Different types of HDPE pipe dending manual machine Japan

1.According to the type of power: hydraulic hdpe pipe bending machine, electric platform pipe bending machine, pneumatic pipe bending machine, manual pipe bending machine, etc.

2.Classified according to the control method: CNC tube bending machine, semi-automatic tube bending machine, automatic tube bending machine, etc.

3.Classified according to work type: single-head bending machine, double-head bending machine, multi-head bending machine, etc.

4.According to the processing range: micro tube bending machine, small tube bending machine, large tube bending machine, etc.

Feathers of HDPE pipe dending manual machine

1. The hdpe pipe bending machine adopts the japan technologe touch screen plus numerical control module, and the dialogue operation is simple and easy to set up;

2, the bed structure is stable, not easy to deform;

3. Each file can be set with 16 bend angles, and the memory can store 16 sets of files;

4, all slow positioning function, the angle of the bend is stable, the repeatability is ±0.1 °;

5. The error message is displayed on the screen to help the operator to eliminate it immediately;

6. Provide self-developed coordinate conversion elbow processing value, software can be installed and edited on the desktop computer.

Main parameter of HDPE pipe dending manual machine :

|

M achine type |

sev -3028 |

|

Pvc work object |

pvc / pp / pex/hdpe |

|

effective thermal bending diameter |

6-20mm |

|

thickness of machining pipe |

1-3mm |

|

maximum heating temperature |

300℃ |

|

bending angle |

mould shape |

|

production speed |

20s |

|

maximum production |

1000-2000pcs./d |

|

mould pressure |

100kg |

|

speed of mould |

2-10s |

|

power |

5-10kw |

|

voltage |

110-410v |

|

machine size |

1200*600*1400mm |

|

machine style |

vertical type |

|

machine color |

customiz ed |

|

warranty period |

1 year |

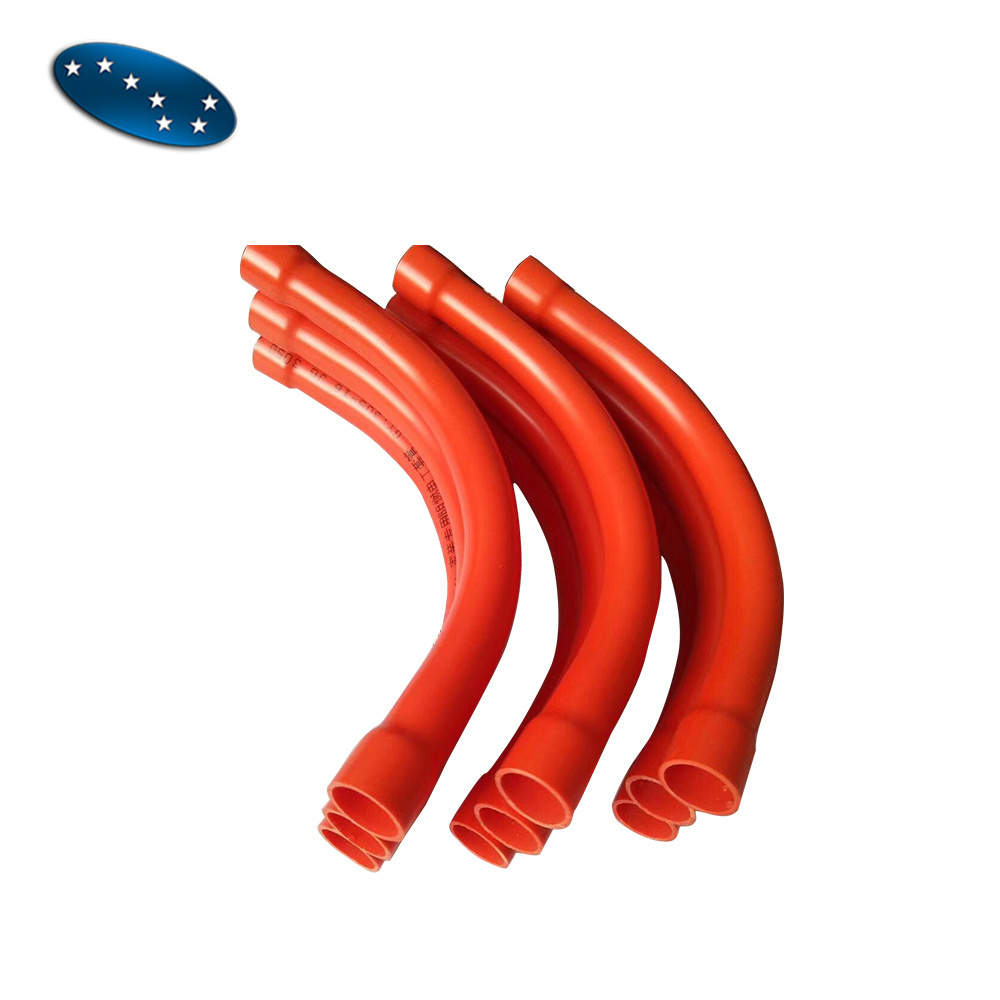

Main products images and machine photos of HDPE pipe dending manual machine

Packaging & Delivery

Packaging Details:

Standard wood case , PE stretch wrapping film and sea-worthy packaging for plastic pvc pipe bender bending machine

Delievery time:

30 working days