- Product Details

- {{item.text}}

Quick Details

-

Package:

-

25KG

-

Application:

-

Injection Molding

-

Certificate:

-

COA

-

Material:

-

PPO (PPE)+PS

-

Type:

-

Vrigin

-

Grade:

-

Injection Grade

-

Advantage:

-

PPO PPE Resin

-

Shape:

-

Granular

Quick Details

-

Place of Origin:

-

JIA

-

Feature:

-

Light Specific Gravity

-

Product name:

-

PPO GF30

-

Package:

-

25KG

-

Application:

-

Injection Molding

-

Certificate:

-

COA

-

Material:

-

PPO (PPE)+PS

-

Type:

-

Vrigin

-

Grade:

-

Injection Grade

-

Advantage:

-

PPO PPE Resin

-

Shape:

-

Granular

Industrial PPO Resin PPE Material

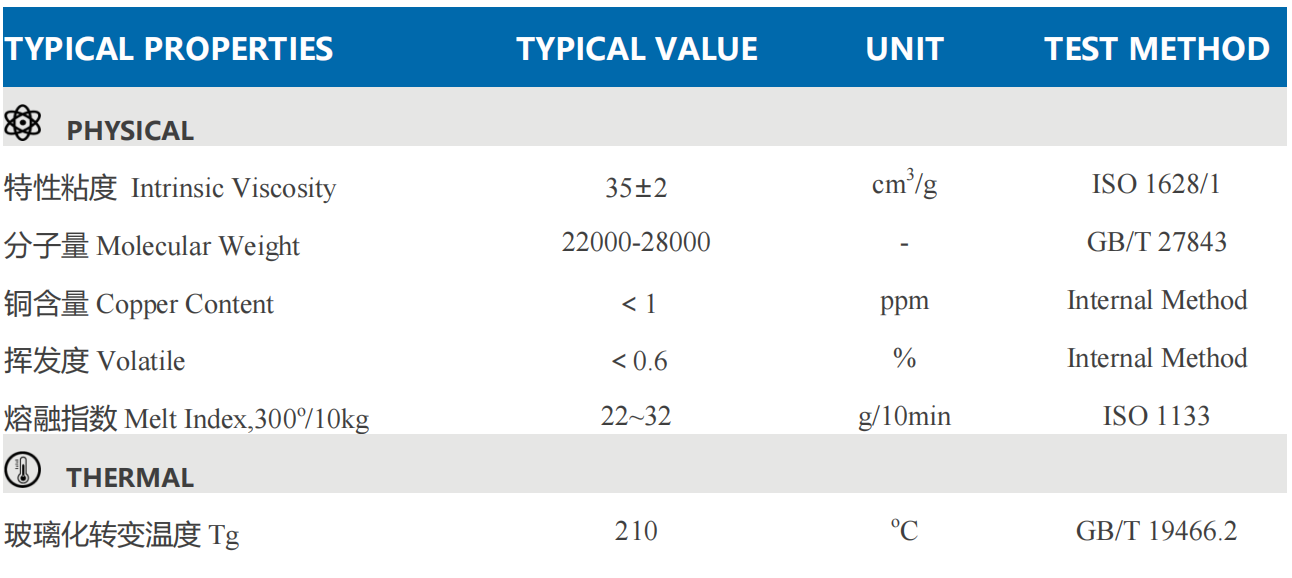

PPO physical and chemical properties

PPO is one of the world's top five general engineering plastics. It has high rigidity and high heat resistance

It has the advantages of high combustion, high strength and excellent electrical properties. In addition, PPO also has the advantages of being green, north-facing, and resistant to pollution. The dielectric constant and dielectric loss of PPO are one of the smallest among engineering plastics and are almost unaffected by temperature and humidity. It can be used for low, medium and high frequency electrical power generation (the smaller the dielectric constant, the better the insulation). The load deformation temperature of PPO reaches more than 190°C and the degeneration temperature is -170°C.

PPO material properties:

1. It is white particles. It has good overall performance and can be used in 120-degree steam. It has good electrical insulation and low water absorption, but it has a tendency of stress cracking: modified polyphenylene ether can eliminate stress cracking.

2. It has outstanding electrical insulation, excellent water resistance and good dimensional stability.

3. MPPO is a modified material made by blending PPO and HIPS. All materials on the market are this kind of material.

4. It has high heat resistance, with a glass transition temperature of 211 degrees and a melting point of 268 degrees. It has a tendency to decompose when heated to 330 degrees. The higher the PPo content, the better the heat resistance, and the heat distortion temperature can reach 190 degrees.

5. It has good flame retardancy, is self-extinguishing, and has moderate flammability when mixed with HIPS. Light weight, non-toxic and can be used in the food and pharmaceutical industries.

It has poor light resistance and will change color if used in the sun for a long time.

6. Can be blended and modified with ABS, HDPE, PPS, PA, HIPS and glass fiber

Product Description

PPE/PPO is a medium-high molecular weight polymer based on Polyphenylene Ether (PPE). This material is intended for use as an additive or a building block in a variety of thermoplastics and thermoplasticelastomers such as Styrenic Block Copolymers. PPE powder can be used to improve properties (i.e.HeatDistortion and Creep Resistance). It is hydrolytically stable and non-hydroscopic(typically less than 0.2% wateruptake). The polymer is soluble in common organic solvents like toluene, chloroform and THF . Chemical name: Poly (2,6-dimethyl-,1,4-phenylene ether)(PPE)Formula:(CH;O)n .

Hot Searches