- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

FORCAR

-

Warranty:

-

Whole life

-

Model Number:

-

FC-FORGED

-

OEM:

-

Yes

-

Certification:

-

TUV/JWL/VIA/ SFI /ISO16949

-

MOQ:

-

4 Pieces

-

Keyword:

-

Forged wheels

-

Market:

-

Global

-

Delivery time:

-

40 Days

-

HOLE:

-

Customize

Quick Details

-

Finishing:

-

silver

-

Width:

-

Customize

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

FORCAR

-

Warranty:

-

Whole life

-

Model Number:

-

FC-FORGED

-

OEM:

-

Yes

-

Certification:

-

TUV/JWL/VIA/ SFI /ISO16949

-

MOQ:

-

4 Pieces

-

Keyword:

-

Forged wheels

-

Market:

-

Global

-

Delivery time:

-

40 Days

-

HOLE:

-

Customize

Forcar Two-Pieces Gold Center Piece Luxurious Passenger Car 5 Holes Made in China Forged Wheel

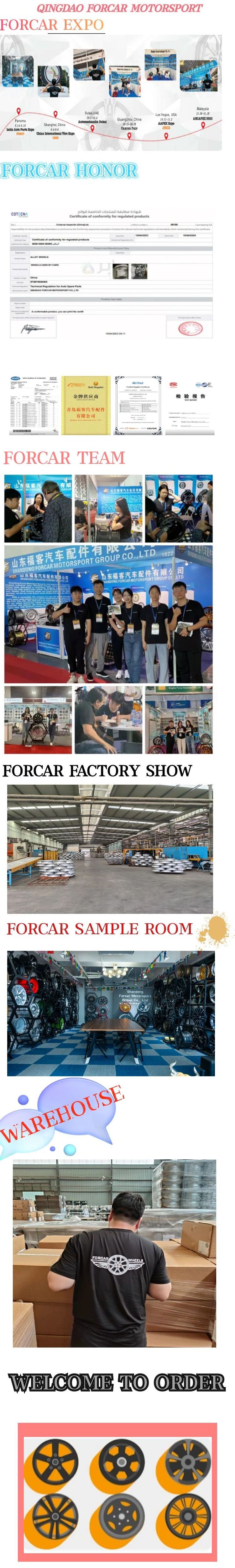

Here is Andrew from Shandong Forcar Motorsport Group Company . With over 10 years experience designing and manufacturing alloy wheels, Forcar Motorsport wheels and Forcar Motorsport design team win the trust and praise among all clients. We also can provide special services for Aluminum Alloy wheels, Alloy wheels, car aluminum alloy wheel, car wheels, rims, wheel rims, dish, OEM acceptable. Please allow me briefly introduce as follows:

Forcar Aluminum A356.2 Casting & T6 Forged Alloy Wheels from 10inch to 28inch with VIA, JWL, TUV, ISO, DOT certificates;

1. Chemical composition: A356&A356.2 alloy steel(Si 6.5-7.5, Mg 0.30-0.45, Ti<0.2, Fe<0.12 Mn<0.1 Cu<0.05 Zn<0.05 Al)

2. Finishing: Black, silver, gunmetal, matt black, grey, hyper black, hyper silver, machined face, machined lip, color line, chrome, vacuum chrome, anodized, full Polish, milling, sand blast, two colors, etc.

3. Process: Lower pressure, Gravity casting, Forged

4. Quality Guarantee: ISO/TS 16949: 2000quality system, German TUV, America SFI, DOT, Japanese VIA, JWL, ISO 9001: 2008quality system, the national mandatory "C" certification

OEM process

1. Design according to customer's sample or photos;

2. Making a new design according to different wheels pattern or concept;

3. Making original design according to customer's sketch or concept drawing;

4. Car Fitment Checking;

5. Strength simulation and optimization before mold development

Wheel Rims Sample or Pictures→Deposits→ Drawings→Mould→Production→Wheel Sample→Testing (strict quality control including X-ray, Air Tightness, Bending, Impact, Blance, CMM, Salt Spray...)

| Wheel Size | Carton size | PCS/20GP | PCS/40GP | PCS/40HQ |

| 18X7.0 | 510X510X220 | 454 | 944 | 1188 |

| 18X7.5 | 510X510X230 | 435 | 903 | 1137 |

| 18X8.0 | 510X510X245 | 408 | 847 | 1067 |

| 18X8.5 | 510X510X255 | 392 | 814 | 1025 |

| 18X9.0 | 510X510X270 | 370 | 769 | 968 |

| 18X9.5 | 510X510X280 | 357 | 741 | 934 |

| 18X10 | 510X510X295 | 339 | 704 | 886 |

| 18X10.5 | 510X510X305 | 328 | 681 | 857 |

| 18X12 | 510X510X345 | 290 | 602 | 758 |

| 19X7.5 | 535X535X230 | 395 | 820 | 1033 |

| 19X8.0 | 535X535X245 | 371 | 770 | 970 |

| 19X8.5 | 535X535X255 | 356 | 740 | 932 |

| 19X9.5 | 535X535X280 | 324 | 674 | 848 |

| 19X10 | 535X535X295 | 308 | 640 | 805 |

Contact: