- Product Details

- {{item.text}}

Quick Details

Quick Details

-

Place of Origin:

-

Henan, China

Chrome ore is the imporant source of metal chromium and ferrochrome alloy. most chrome ore must be processed by the chrome ore processing plants. The mainly chrome ore beneficiation method is gravity separation. so the mainly used chrome ore concentrating equipments are jigging machine (sometimes it is called jig concentrator, jig separator), concentrating table, spiral classifiers, etc

Chromite ore beneficiation machines are allocated according to the specific natures of the chrome ore. The main methods for chrome beneficiation are mainly gravity separation and magnetic separation.

After crushing by the crushers, chrome grains are liberated or dissociated from the gangue and the mixed ore can be fed to the separation processing for the secondary processing stages.

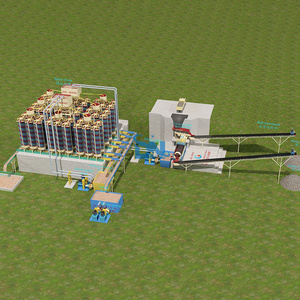

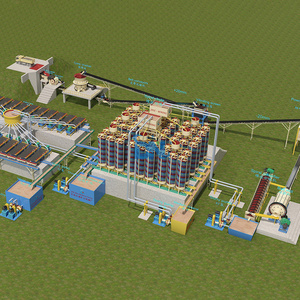

Chromite concentrates by sprial concentrator

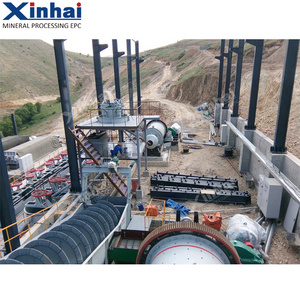

Chromite beneficiation plant in Zimbabwe

Spiral concentrator (spiral chute) is a gravity separation equipment of separation different weight mineral by inertial centrifugal force pulp produced in helix turning motion, it widely used in enrichment of particle size 0.3-0.02mm fine minerals like iron, tin, chromite, ilmenite, tungsten, zinc, tantalum-niobium, gold, coal , monazite, rutile, zircon and other low-grade ores, and non-metallic minerals which have a big enough specific gravity difference.

Ore pulps are uniformly fed into machine and form different layers as they pass across chute. Heavy minerals precipitate to bottom and are moved toward inner edge by the comprehensive action of various forces; light minerals are moved toward outer inner due to the speedy rotation. As a result, mineral particles with different density are divided into three zones---concentrate, middling and tailing.

Our spiral concentrator (spiral chute) is made of the fiberglass lined with wear-resistant resin and emery cover; the advantages are light, moisture proof, anti-rust, wear proof, anti corrosion, no noise and non power required.