- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

kspack

-

Dimension(L*W*H):

-

Depends on the machine model

-

Weight:

-

600000 KG

-

Product name:

-

Automatic 3 5 7 corrugated cardboard making line/corrugated machine

-

Bag type::

-

carton box

-

Material::

-

cast iron

-

Core paper::

-

125-200g/m2

-

using area::

-

paperboard packaging line

-

Keywords:

-

Automatic 3 5 7 corrugated cardboard making line

-

Function:

-

produce the 3 .5 ply corrugated board

-

Application Fields:

-

produce the corrugated box

-

Speed:

-

100-150 M/min

-

size:

-

1400-2500mm

Quick Details

-

Application:

-

Food, Beverage, Commodity, Chemical, Machinery & Hardware, APPAREL, Textiles, Cigarettes, Tobacco

-

Packaging Material:

-

Plastic, Paper, Metal, Wood

-

Voltage:

-

220V/380V

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

kspack

-

Dimension(L*W*H):

-

Depends on the machine model

-

Weight:

-

600000 KG

-

Product name:

-

Automatic 3 5 7 corrugated cardboard making line/corrugated machine

-

Bag type::

-

carton box

-

Material::

-

cast iron

-

Core paper::

-

125-200g/m2

-

using area::

-

paperboard packaging line

-

Keywords:

-

Automatic 3 5 7 corrugated cardboard making line

-

Function:

-

produce the 3 .5 ply corrugated board

-

Application Fields:

-

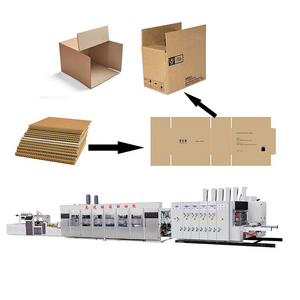

produce the corrugated box

-

Speed:

-

100-150 M/min

-

size:

-

1400-2500mm

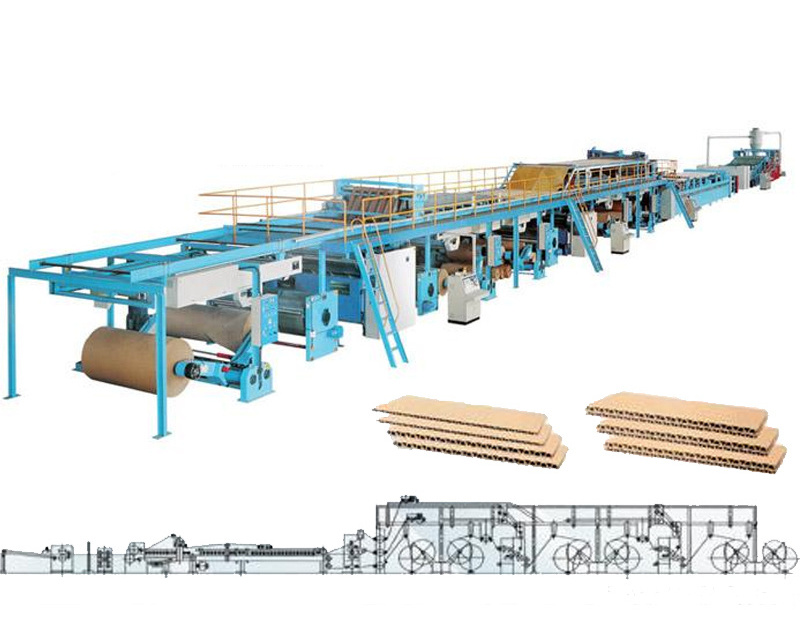

Automatic 3 5 7 corrugated cardboard making line/corrugated machine/carton box manufacturering plant

technical parameter :Automatic 3 5 7 corrugated cardboard making line/corrugated machine/carton box manufacturering plant

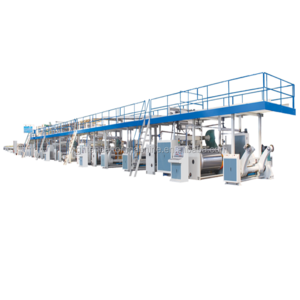

Complete corrugated paperboard production line is compose of shaftless mill roll stand, fingerless type single facer( vacuum suction type), preheater, double bridge,gluer machine, double facer machine, cut off machine, slitter scorer machine, stacker and glue making system

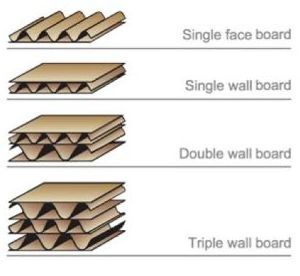

3-layer,5-layer,7-layer production line are all avalaible.

Width from 1400mm to 2500mm.

production speeds from 60-250 meters/min.

Customer's special needs catered by experienced corrugated company.

We can supply a complete corrugator or individual equipment to complete your own line

NOTE: the customer-owned part

1. Steam heating system 4000kg/Hr a steam boiler the pressure 1.4-1.6MPa

The steam pipeline and the back to the gas drainage pipe of vave on equipment

2. air compression pump, compressed air line, glue tube

3. the source of electricity wire access to operation counter and cable routing management

4. the source of water, water pipeline,bucket

5. water, electricity, gas ground plane to stall civil work

6. test base paper used, corn starch(potato), industrial caustic soda, borax etc. material

7. equipment oil, lubricating oil, hydraulic oil, grease and high temperature grease

Automatic 05 Ply Box Making machine/carton machine/corrugated box machinery CE machinery make products

FIRST Process make our corrugated by corrugated board production line