- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

ZX

-

Model Number:

-

ZX

-

Color:

-

natural or white standard color UV black and red, yellow ,green ,blue

-

Operating temperature:

-

-40 to 85*C

-

type:

-

self-locking

-

width:

-

most of the sizes are available now

-

using:

-

High tensile strength

-

MOQ:

-

20,000PCS

-

Packaging:

-

plastic bag and master cartons

Quick Details

-

Type:

-

Self-locking

-

Material:

-

Nylon

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

ZX

-

Model Number:

-

ZX

-

Color:

-

natural or white standard color UV black and red, yellow ,green ,blue

-

Operating temperature:

-

-40 to 85*C

-

type:

-

self-locking

-

width:

-

most of the sizes are available now

-

using:

-

High tensile strength

-

MOQ:

-

20,000PCS

-

Packaging:

-

plastic bag and master cartons

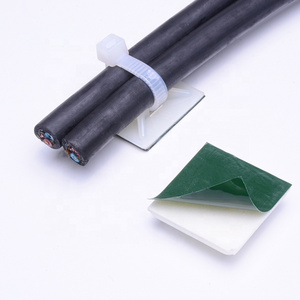

Favorable price with superior quality quick release cable tie

1.Summary

We mainly manufacture cable ties with the most competitive price, best quality, satisfying services and easier cooperation. All these make us obtain more customers from worldwide. We sincerely hope to cooperate with your esteemed company.

1: All kinds of cable ties available, Including self-locking nylon cable ties, push mount tie, mountable head ties, releasable cable ties, double locking cable ties, knot ties and marker ties.

2: Characteristic: Heat resisting, Acid & erosion control, insulate well and apt to age.

3: Fire: Fire-retardant

4: Temperature: -35oC to 85oC.

5: Colors: natural(white,standard color),other colors are available as requested

6: Usage: after bunding wires,fix them on plate with screw.

7: Packing: standard packing, other packing is available as requested.

8: Delivery Detail: 10-15 days(Depend on your order quantity) after confirm order.

2.Items and Technical Traits

|

Item No. |

Length(L) |

Width(W) |

Bundle |

Tensile strength |

||

|

Inch |

MM |

MM |

Diameter MM |

LBS |

KGS |

|

|

2.2*60 |

2.4" |

60 |

2.5 |

2—11 |

18 |

8 |

|

2.5*80 |

3.2" |

80 |

2—16 |

|||

|

2.5*100 |

4.0" |

100 |

2—22 |

|||

|

2.5*120 |

4.7" |

120 |

2—30 |

|||

|

2.5*150 |

6.0" |

150 |

2—35 |

|||

|

2.5*160 |

6.3" |

160 |

2—40 |

|||

|

2.5*200 |

8.0" |

200 |

2—50 |

|||

|

3.6*100 |

4.0" |

100 |

3.6 |

3—22 |

40 |

18 |

|

3.6*120 |

4.7" |

120 |

3—30 |

|||

|

3.6*150 |

6.0" |

150 |

3—35 |

|||

|

3.6*180 |

7.1" |

180 |

3—42 |

|||

|

3.6*200 |

8.0" |

200 |

3—65 |

|||

|

3.6*250 |

10" |

250 |

3—70 |

|||

|

3.6*300 |

12" |

300 |

3—80 |

|||

|

3.6*370 |

14.6" |

370 |

3—85 |

|||

|

4.8*100 |

4.0" |

100 |

4.8 |

4—22 |

50 |

22 |

|

4.8*120 |

4.7" |

120 |

4—30 |

|||

|

4.8*150 |

6.0" |

150 |

4—35 |

|||

|

4.8*180 |

7.1" |

180 |

4—50 |

|||

|

4.8*200 |

8.0" |

200 |

4—65 |

|||

|

4.8*250 |

10" |

250 |

4—80 |

|||

|

4.8*300 |

12" |

300 |

4—85 |

|||

|

4.8*370 |

14.6" |

370 |

4—22 |

|||

|

4.8*100 |

4.0" |

100 |

4—30 |

|||

|

4.8*120 |

4.7" |

120 |

4—35 |

|||

|

4.8*150 |

6.0" |

150 |

4—50 |

|||

|

4.8*180 |

7.1" |

180 |

4—65 |

|||

|

4.8*200 |

8.0" |

200 |

4—80 |

|||

|

7.2*200 |

8.0" |

200 |

7.6 |

5—50 |

120 |

55 |

|

7.2*250 |

10" |

250 |

5—65 |

|||

|

7.2*300 |

12" |

300 |

5—80 |

|||

|

7.2*350 |

14" |

350 |

5—82 |

|||

|

7.2*370 |

14.6" |

370 |

5—85 |

|||

|

7.2*400 |

16" |

400 |

5—105 |

|||

|

7.2*450 |

18" |

450 |

5—118 |

|||

|

7.2*500 |

20" |

500 |

5—150 |

|||

|

8.8*400 |

16" |

400 |

8.8 |

6—105 |

170 |

75 |

|

8.8*450 |

18" |

450 |

6—118 |

|||

|

8.8*500 |

20" |

500 |

6—105 |

|||

|

8.8*500 |

21.6" |

550 |

6—160 |

|||

|

8.8*600 |

23.6" |

600 |

6—170 |

|||

|

8.8*650 |

25.6" |

650 |

6—185 |

|||

|

8.8*700 |

27.6" |

700 |

6—190 |

|||

|

8.8*760 |

30" |

760 |

6—200 |

|||

|

8.8*800 |

31.5" |

800 |

6—230 |

|||

|

8.8*900 |

35.5" |

900 |

6—265 |

|||

4.Our mold workshop and injection moulding workshop

5.Why choose us?

6.Our service