- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

UNIPRETEC

-

Color:

-

white and ivory

-

Density:

-

3.65 - 3.90 g/cm3

-

Max. Working Temp.:

-

1,400 - 1,700 °C

-

Electrical Insulation:

-

Excellent

Quick Details

-

Material:

-

Alumina Ceramic

-

Place of Origin:

-

Fujian, China

-

Model Number:

-

Customized

-

Brand Name:

-

UNIPRETEC

-

Color:

-

white and ivory

-

Density:

-

3.65 - 3.90 g/cm3

-

Max. Working Temp.:

-

1,400 - 1,700 °C

-

Electrical Insulation:

-

Excellent

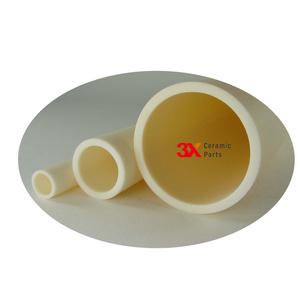

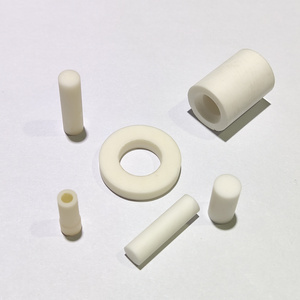

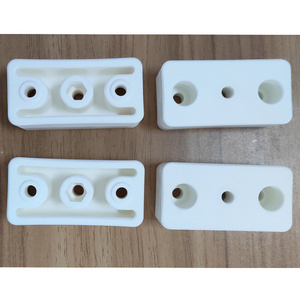

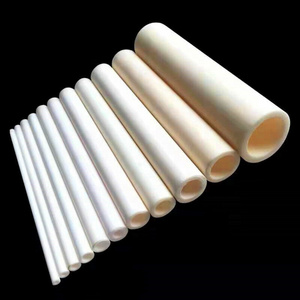

Details Images

Material Introduction

Alumina, or Aluminum Oxide, is a durable fine industrial ceramic that is commonly used in a variety of processing applications. Grind sintered alumina ceramics only using a diamond tool. Alumina ceramic exhibits exceptional hardness and wear resistance, as well as low corrosion, excellent electrical insulation and bio-inertness.

Alumina (Al2O3) is a very heat-stable ceramic material of excellent temperature stability.

|

√ High Voltage Insulator

|

√ High Purity, Max. 99.8%

|

√ Various Available Grades

|

|

√ Hard and Wear Resistant

|

√ High Corrosion Resistance

|

√ High Mechanical Strength

|

|

√ Good Thermal Conductivity

|

√ High Operating Temperature

|

√ Most Favorable Fine Ceramic

|

Al2O3 ceramics with a purity of 95% to 99% are the most commonly used kind of technical ceramics. UNIPRETEC offers a variety of alumina ceramic shaping methods, including molded injection, die pressing, slip casting, extrusion, and cold isostatistically pressing.

Alumina is used in a wide spectrum of purity concentrations, ranging from ultrapure to added-substance grades. Although the purity of Al2O3 in finished products usually ranges between 90 and 99.8%, UNIPRETEC tends to work with materials with a purity of 95 to 99.8 percent.

Product Features

● excellent electrical insulation ●

● good thermal conductivity ●

● corrosion & erosion resistant ●

● thermal shock resistant ●

● high working temperature ●

● low thermal expansion ●

● very hard, wear resistant ●

● high mechanical strength ●

● flexible custom production ●

Material Properties

|

ITEM

|

UNIT

|

Alumina | A950

|

Alumina | A990

|

|

Main Content

|

-

|

95% Al

2

O

3

|

99% Al

2

O

3

|

|

Color

|

-

|

White / Pink

|

Ivory

|

|

Density

|

g/cm

3

|

3.7

|

3.85

|

|

Vickers Hardness

|

Gpa

|

14

|

17

|

|

Flexural Strength

|

Mpa

|

310

|

360

|

|

Compressive Strength

|

Mpa

|

2,200

|

2,500

|

|

Electrical Resistivity

|

Ω·cm

|

>10

14

|

>10

14

|

|

Dielectric Strength

|

KV/mm

|

15

|

17

|

|

Dielectric Constant

|

1 MHz

|

8

|

9

|

|

Thermal Conductivity

|

W/m.K

|

25

|

29

|

|

Max. Working Temperature

|

℃ / °F

|

1,500 / 2,730

|

1,650 / 3,000

|

|

Resistance to Thermal Shock

|

△T(℃)

|

210

|

230

|

|

Thermal Expansion Coefficient (25 - 1,000 ℃)

|

10

-6

/K

|

7 - 9

|

7 - 9

|

∆ The above data is offered for reference and comparison only, exact data will vary depending on the manufacturing method and part configuration.

Inspection

About Us

"Simple things into very complex, can find new areas; Read the complex phenomenon is very simple, can be found that the new law." - - - - - -Isaac Newton

Hot Searches