- Product Details

- {{item.text}}

Quick Details

-

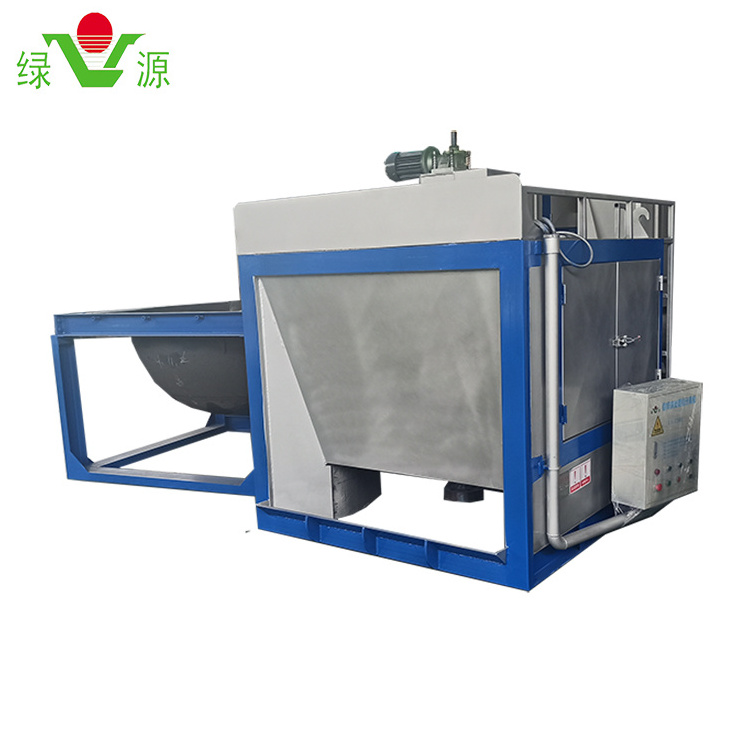

Model:

-

LY-110

-

Material:

-

High temperature and wear resistant cast iron, steel

-

Size:

-

1900*2200*3300mm

-

Colour:

-

Grey and Bule

-

Processing capacity:

-

400kg/pot

-

After Warranty Service:

-

Video technical support

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Lvyuan

-

Weight (KG):

-

6000

-

Model:

-

LY-110

-

Material:

-

High temperature and wear resistant cast iron, steel

-

Size:

-

1900*2200*3300mm

-

Colour:

-

Grey and Bule

-

Processing capacity:

-

400kg/pot

-

After Warranty Service:

-

Video technical support

Product Description

Specification

|

Mode

|

LY-110

|

|

Motor Power

|

5.5KW

|

|

The rotary speed of stiming paddle

|

22r/min

|

|

Processing capacity /pot

|

400kg

|

Packing & Delivery

Mechanical products are packaged in sections, the main structure is exposed, and the screws and accessories are packaged in cartons or other packaging. Because the mechanical part is a heavy machine, the volume and weight are relatively large, and it is generally operated by forklifts. It is bare packaging.

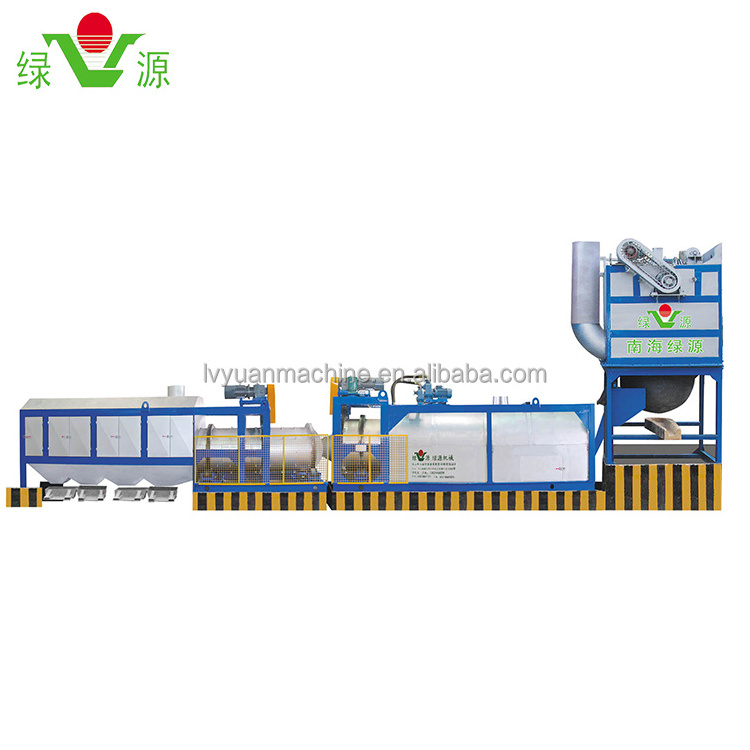

Work flow chart of aluminum ash recycling production line

First, pick up the hot aluminum ash from the melting furnace and put it into the aluminum ash hopper. Use a forklift to load the ash. The hot aluminum ash enters the fry ash pan. The stirring paddle is used to stir. After stirring, the molten aluminum and the aluminum ash are separated, and the molten aluminum flows into the aluminum hopper. , After the aluminum water flows, the remaining aluminum ash enters the ash cooler, which uses water spray to cool to below 80 degrees, and the cooled aluminum ash enters the ball mill sieving machine for ball milling and crushing of the aluminum ash. The crushed aluminum ash enters a three-stage sieve to separate out fine-particle aluminum ash, medium-particle aluminum ash and coarse-particle aluminum ash. Among them, the fine-particle aluminum ash is awakened and harmlessly treated, the medium-particle aluminum ash is used to cool the ash during frying, the coarse-particle aluminum ash is directly returned to the furnace for remelting, and the aluminum ash recovery production line, the aluminum recovery of aluminum reaches more than 85%.

Hot Searches