- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Glasino

-

Voltage:

-

380V

-

Power:

-

15kw

-

Weight:

-

3000 kg

-

Name:

-

Glass Straight Line Double Edge Polishing Machine

-

Function:

-

Glass Grinder Edging Polishing

-

Usage:

-

Glass Edging Polisher Processing

-

Application:

-

Glass Industry

-

Keyword:

-

Glass Polisher

-

Max glass size:

-

4200x2500mm

Quick Details

-

Machine Type:

-

Glass Edging Machine

-

Glass Thickness:

-

3-19mm

-

Production Capacity:

-

100%

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Glasino

-

Voltage:

-

380V

-

Power:

-

15kw

-

Weight:

-

3000 kg

-

Name:

-

Glass Straight Line Double Edge Polishing Machine

-

Function:

-

Glass Grinder Edging Polishing

-

Usage:

-

Glass Edging Polisher Processing

-

Application:

-

Glass Industry

-

Keyword:

-

Glass Polisher

-

Max glass size:

-

4200x2500mm

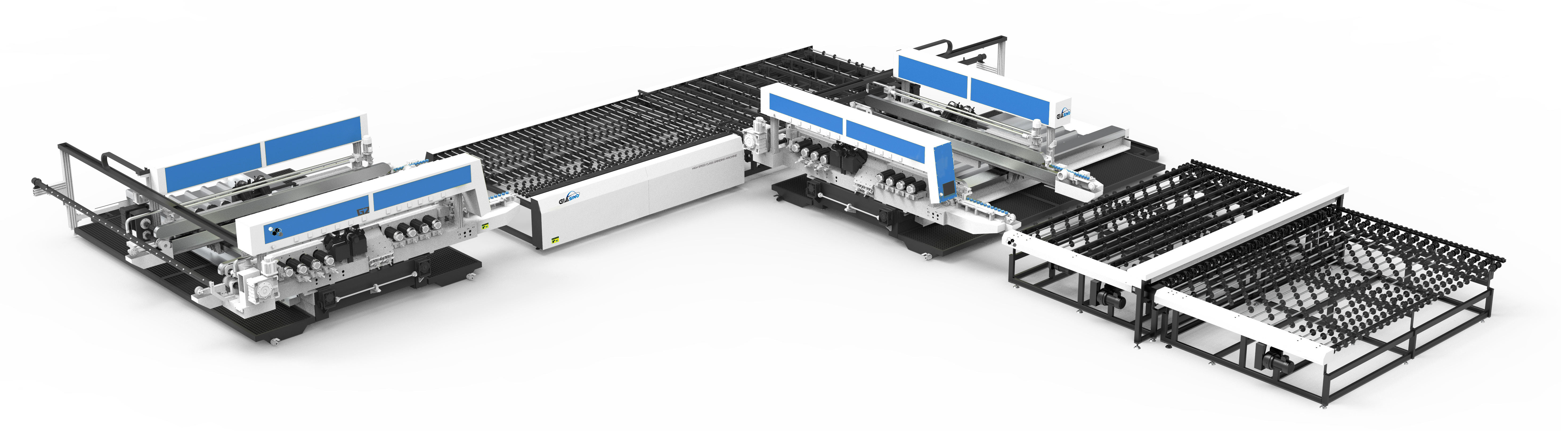

High Speed Double Edging Machine Production Line, Glass Double Edger

Product Description

GSZM2042+GSTL4225+GSZM2025 Glass Straight Line Double Edging Machine production line is an economic, high efficiency, high precise, reliable product for all size of flat glass, laminated glass and Low-E glass on mass production.

1.Opening and closing of structure adopt ball screw and straight line lead rail.

2.Grinding wheel adopts double V type guide rail with high precision,smooth operation and small vibration. 3.Semi-automatic for polishing.

4.Upper angle chamfer adopts ball screw and linear guide,precise orientation.

5.Automatically lifted for cleating bracket, which can be reached to 120mm.

6.Main transmission drive adopts mechanical frequency conversion to adjust the speed, upper posited, convenient for changing and maintenance.

7.Adopt annular synchronous belt and pneumatic positioning device for conveying glass, with smooth transmit and accurate positioning.

8.Adopt human-computer interface and PLC controlling system, easy operation.

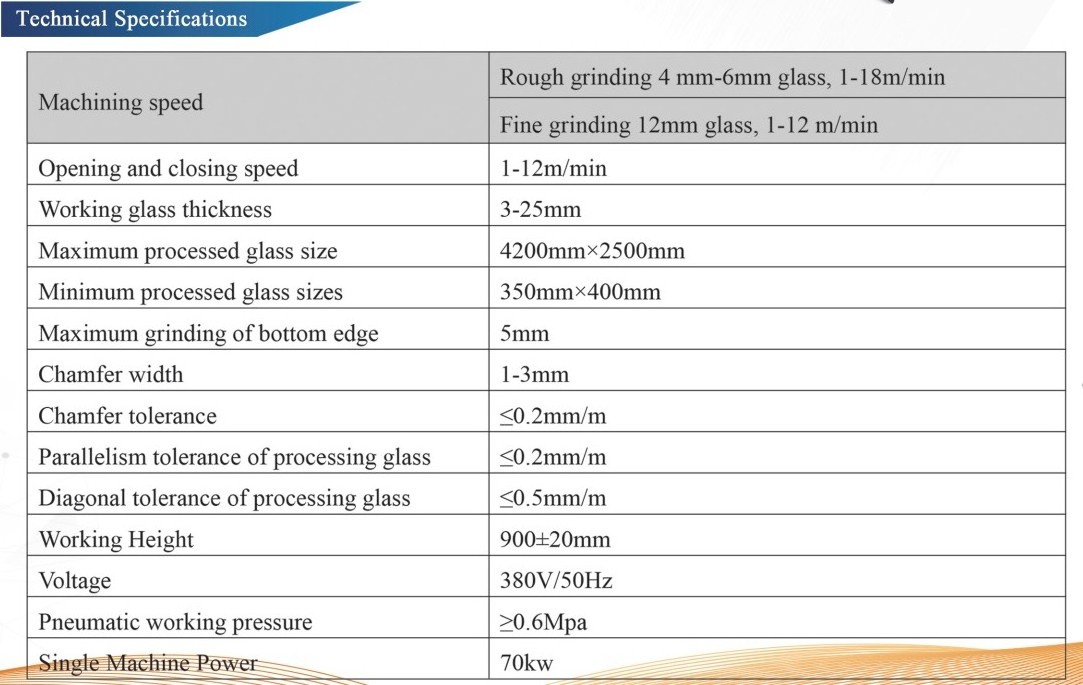

Technical parameters

Details Images

Heavy duty basement

.

Main drive mechanism

Width adjustment mechanism

Grinding head motor device

Packing & Delivery

Hot Searches