- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

100%

-

Voltage:

-

380V

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

ZYL

-

Dimension(L*W*H):

-

2700*1400*1900MM

-

Weight:

-

3100 KG

-

Product name:

-

Automatic can Filling capping Machine

-

Bottle type:

-

Can,metal

-

Machine type:

-

Automatic Filling Capping Production Line

-

Capacity:

-

8000-90000 CPH

-

Function:

-

liquid filling capping

-

Material:

-

Stainless Steel 304/316

-

Control:

-

PLC controller

-

Filling nozzles:

-

12 Nozzles(customized)

-

Advantage:

-

Automatic Working

-

Can height:

-

39-160mm

Quick Details

-

Machinery Capacity:

-

4000BPH, 8000BPH, 12000BPH, 6000BPH, 20000BPH, 16000BPH, 2000BPH, 1000BPH, 36000BPH

-

Packaging Material:

-

Metal

-

Filling Material:

-

Beer, Juice, Milk, Water, Oil, Other

-

Filling Accuracy:

-

100%

-

Voltage:

-

380V

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

ZYL

-

Dimension(L*W*H):

-

2700*1400*1900MM

-

Weight:

-

3100 KG

-

Product name:

-

Automatic can Filling capping Machine

-

Bottle type:

-

Can,metal

-

Machine type:

-

Automatic Filling Capping Production Line

-

Capacity:

-

8000-90000 CPH

-

Function:

-

liquid filling capping

-

Material:

-

Stainless Steel 304/316

-

Control:

-

PLC controller

-

Filling nozzles:

-

12 Nozzles(customized)

-

Advantage:

-

Automatic Working

-

Can height:

-

39-160mm

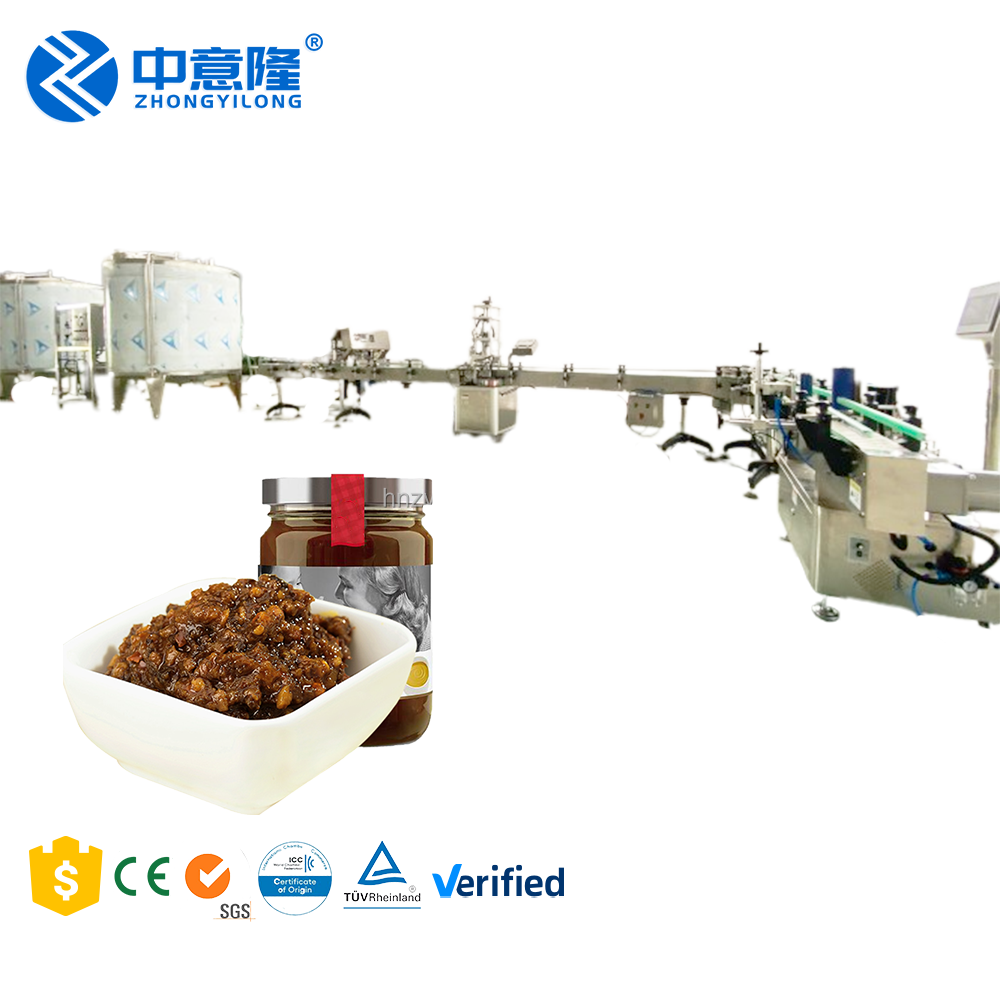

Products Description

zhongyilong: A Trusted Name in filling packing Business

we provides the best filling packing euioment for business, home, and industry. Select us for your solution Tailor made, provide you complete turnkey solution zhongyilong’s expertise in liquid packaging ensures the perfect combination of process design and product-line engineering. With the established process design system of various liquid packaging fields such as beverages, dairy products, liquors, condiments, and daily chemical products, we can provide customized turnkey solution for your project considering different packaging forms and specific factory layouts.

Automatic Single head Bottle Peanut Butter Chili Sauce Filling Machinery Magnetic Pump Hand Wash Gel Filler Milk Dispenser

Soybean paste filling machine specializes in filling production of soybean paste, soybean paste, bean paste, chili paste, fresh hot sauce, etc. Soybean paste filling equipment is a machine for mechanically filling soybean paste. The main raw materials of soybean paste are soybeans and flour. It is a condiment produced by the interaction of various microorganisms and biochemical reactions. At the same time, sesame oil, soybean oil, monosodium glutamate, chili and other raw materials can be formulated to increase the variety of soybean paste.

medium viscosity products,is the ideal equipment for general cosmetic, liquor, food, oil factory,etc.

Major Characteristics:

1. The flow control devices of each filling head are independent of each other, precision adjustment is very convenient.

2. The material of the machine material contact part can use the food grade material according to the products feature, in line

with the GMP standard.

3. With regular filling, no bottle no filling, filling quantity/production counting function etc features.

4. Convenient maintenance,no need any special tools.

5. Using drip tight filling head,no leaking.

Performance Characteristics of Soybean Paste Filling Machinery:

1. Fast filling speed, fast and accurate filling of materials.

2. Imported components, using foreign pneumatic components and electronic control components, stable performance

3. The hygienic safety of the soybean paste filling machines are guaranteed, and the material contact parts are made of 316L stainless steel, which meets GMP requirements.

4. Humanized and intelligent device, convenient adjustment, accurate filling volume and counting function.

5. In this case, a filling production line has been produced, which can fill bottles of various sizes and shapes.

1. Fast filling speed, fast and accurate filling of materials.

2. Imported components, using foreign pneumatic components and electronic control components, stable performance

3. The hygienic safety of the soybean paste filling machines are guaranteed, and the material contact parts are made of 316L stainless steel, which meets GMP requirements.

4. Humanized and intelligent device, convenient adjustment, accurate filling volume and counting function.

5. In this case, a filling production line has been produced, which can fill bottles of various sizes and shapes.

|

Applicable Spece

|

50~1000g

|

|

Production Ability

|

2000-2500 Bottles/Hour

|

|

Filling Error

|

Acuities ± 2% Standard Outfit Quantity

|

|

Power

|

4.5kw

|

|

Requirements Compressed Air Pressure

|

0.4-0.6 Mpa

|

|

Speed Control

|

Frequency Control

|

|

LAN Noise

|

50dB Acuities

|

|

Machine Weight

|

About 600Kg

|

|

Machine Dimension

|

2400×1200×2300 (mm)

|

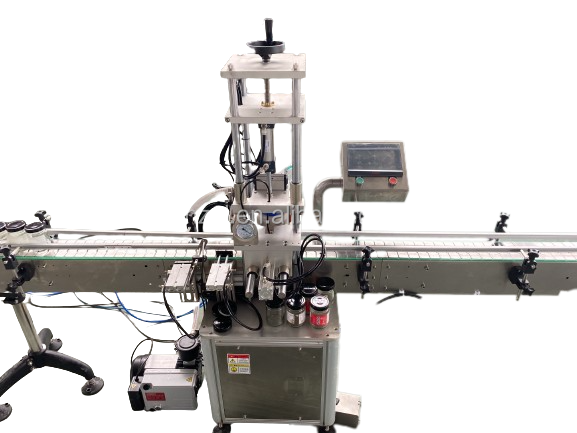

Vacuum capping machine

generally refers to the equipment used for vacuum capping and packaging glass bottles and jars. Due to the reliable full sealing technology, the ideal vacuum degree can be achieved by configuring a low-power vacuum pump. The vacuum degree can be set as required. And its moulds for glass jar sealing are customized according to the size and shape of the can. The standard configuration is a glass bottle with an iron cap. It is a semi-automatic vacuum bottle capping machine. The bottle and cover should be put by hand, including putting and taking out bottles before and after vacuum capping. It usually applies to small and medium production. For large output, we provide the fully automatic linear vacuum capper and rotary type capper.

Applications of vacuum cap sealing machine

In life, all the products using the glass bottle and iron cover are applicable. Widely used in food, canned, beverage, condiment,

health care products, and other industries. Such as honey, sesame sauce, mushroom sauce, chili sauce, blueberry sauce, jam, canned

fruits, canned vegetables, soy products, ketchup, etc. The vacuum capper is suitable for round glass jars, square cans, and other

shapes.

In life, all the products using the glass bottle and iron cover are applicable. Widely used in food, canned, beverage, condiment,

health care products, and other industries. Such as honey, sesame sauce, mushroom sauce, chili sauce, blueberry sauce, jam, canned

fruits, canned vegetables, soy products, ketchup, etc. The vacuum capper is suitable for round glass jars, square cans, and other

shapes.

Welcome to contact us to get more details.

High Production Automatic Bottle Labeling Machine

As a producer of consumer items, you know shoppers decide in fractions of a second what they’re going to buy. With labellers from us, you can be sure that your product’s an eye-catcher. Whether it’s hotmelt, cold-glue, pressure-sensitive labels or sleeves: our labelling technology effortlessly masters every variant of dress – and if you want, even all of them together on a single machine.

Product details

Machines to Form Production Line

Due to the glass jar capper occupying a small space, having the characteristics of cost-effective, wide applications, easy usage,reliability, and mobility, it is proper for small production workshops, special specifications usage, and laboratories’ use. It also can match with other machines to form production lines in order, like bottle washing machines, liquid filling machines, cap feeding machines, labeling machines, conveyors, etc. We also provide thoughtful after-sales services to satisfy you. If you want to know more details and its price, welcome to contact us.

Due to the glass jar capper occupying a small space, having the characteristics of cost-effective, wide applications, easy usage,reliability, and mobility, it is proper for small production workshops, special specifications usage, and laboratories’ use. It also can match with other machines to form production lines in order, like bottle washing machines, liquid filling machines, cap feeding machines, labeling machines, conveyors, etc. We also provide thoughtful after-sales services to satisfy you. If you want to know more details and its price, welcome to contact us.

OEM/ODM

Supply bottle&label design and factory layout for free!

How to customize your machine?

We are specialized in providing filling and packaging machines for various liquids.

In order to provide you with appropriate solutions and accurate quotations, we need to know:

1. What kind of liquid?

2. Bottle type (material and shape) and size?

3. Expected filling volume (bph)?

4. Expected functions of the machine (bottle washing, filling, capping? Semi-automatic or fully automatic?)

5. Other functions such as labeling, printing date, packaging, etc?

6. Available layouts?

7. Available voltage/Hz/phase?

8. Other requirements.

Related products

About us

FAQ

Q1: Where is your factory? How can I visit your factory?

A: Our factory is located in Henan Province. If you have a travel plan, we warmly welcome you to visit our factory

Q2: Can you send me a video to show me how the machine works?

A: Of course, we made videos of each machine

Q3: How do I know your machine is designed for my product?

A: You can send us your product samples, and we will test them on the machine

Q4: How do I pay for my order?

Answer: Usually we accept L/C, D/A, D/P, T/T, Western Union, MoneyGram and cash payment

Q5: Do you have a Ce certificate?

A: For each model of machine, it has CE certification

Hot Searches