- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

customized

-

Product name:

-

plastic injection mold housing ABS moulding for brake pedal

-

product material:

-

plastic

-

plastic material:

-

ABS

-

design software:

-

UG, Pro-E, Solidworks, CATIA, Moldflow, etc.

-

mold base:

-

HASCO, LKM and so on

-

cavity:

-

multi or single

-

runner:

-

hot runner/cold runner

-

mold life:

-

300000-500000 shots

-

lead time:

-

25-35 days

-

Certification:

-

ISO9001:2015

Quick Details

-

Shaping Mode:

-

Plastic Injection Mould

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

customized

-

Model Number:

-

customized

-

Product name:

-

plastic injection mold housing ABS moulding for brake pedal

-

product material:

-

plastic

-

plastic material:

-

ABS

-

design software:

-

UG, Pro-E, Solidworks, CATIA, Moldflow, etc.

-

mold base:

-

HASCO, LKM and so on

-

cavity:

-

multi or single

-

runner:

-

hot runner/cold runner

-

mold life:

-

300000-500000 shots

-

lead time:

-

25-35 days

-

Certification:

-

ISO9001:2015

China Manufacturer Injection Mold Molding Service Custom Auto Plastic Parts

1. High quality, competitive cost, durable, delivery on time

2. Professional technical supports and satisfactory customer service

3. 20-year experience in mold design and making

4. Certification: ISO9001: 2015, SGS

|

Product Name

|

High Quality Plastic Injection Mould Maker / Supplier / Manufacturer

|

|

|

|

|||

|

Mold Material

|

S136/2344/718/738/NAK80/P20, etc.

|

|

|

|

|||

|

Plastic Material

|

ABS, PP, PC, PVC, POM, TPU, PC, NYLON, Silicone, Rubber, etc

|

|

|

|

|||

|

Mold Base

|

LKM, HASCO, etc.

|

|

|

|

|||

|

mold Life

|

3k-800k shots (depend on your environment)

|

|

|

|

|||

|

Mold PrecIsion

|

+-0.01mm

|

|

|

|

|||

|

Quality Assurance

|

ISO9001: 2015, SGS, ROHS, TUV

|

|

|

|

|||

|

Custom Feature

|

According to your 2D/3D Drawing or sample provided; Color/Quantity/Unit price/Tooling cost/Tooling size/ are to be discussed

|

|

|

|

|||

|

Our Equipments

|

High speed CNC, Standard CNC, EDM, Wire Cutting, WEDM, Grinder, Plastic Injection Molding Machine from 45-500T available.

|

|

|

|

|||

|

Port of loading

|

FOB Yantian Port/Shenzhen Port, China

|

|

|

|

|||

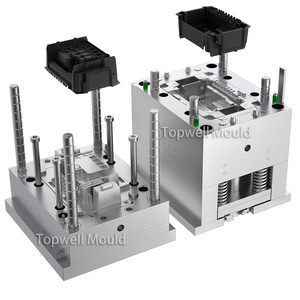

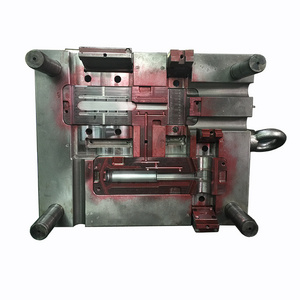

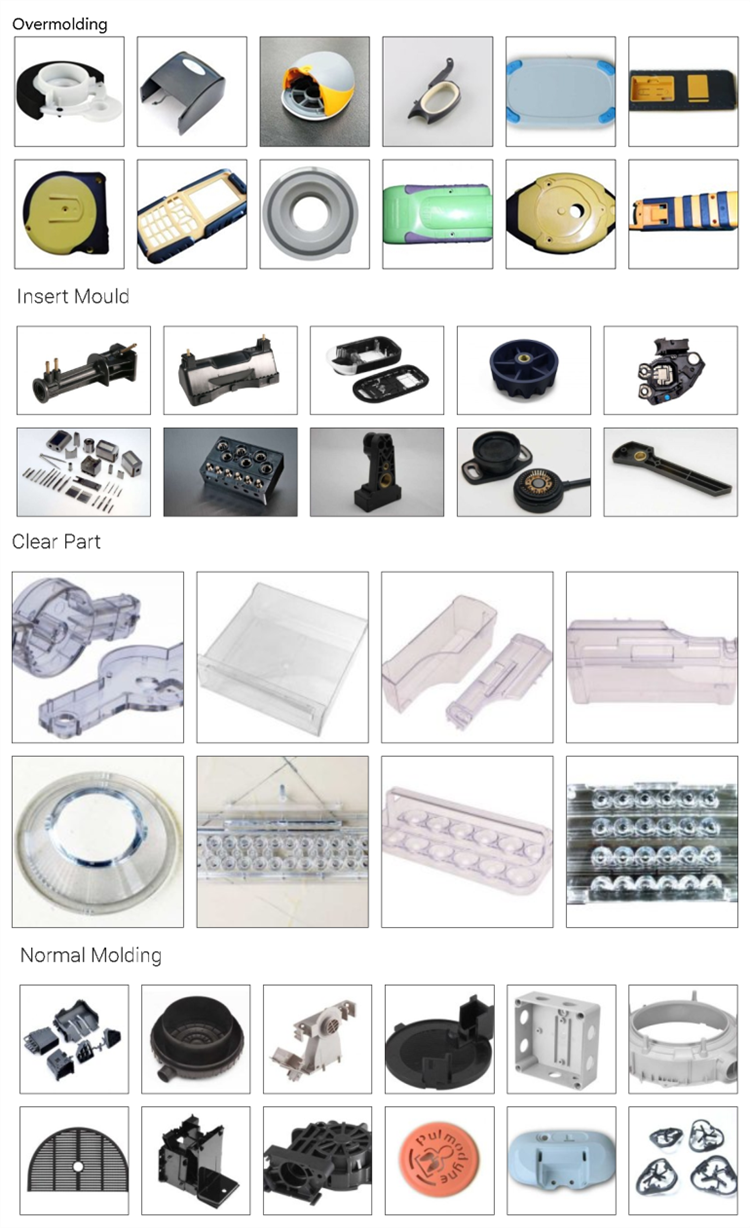

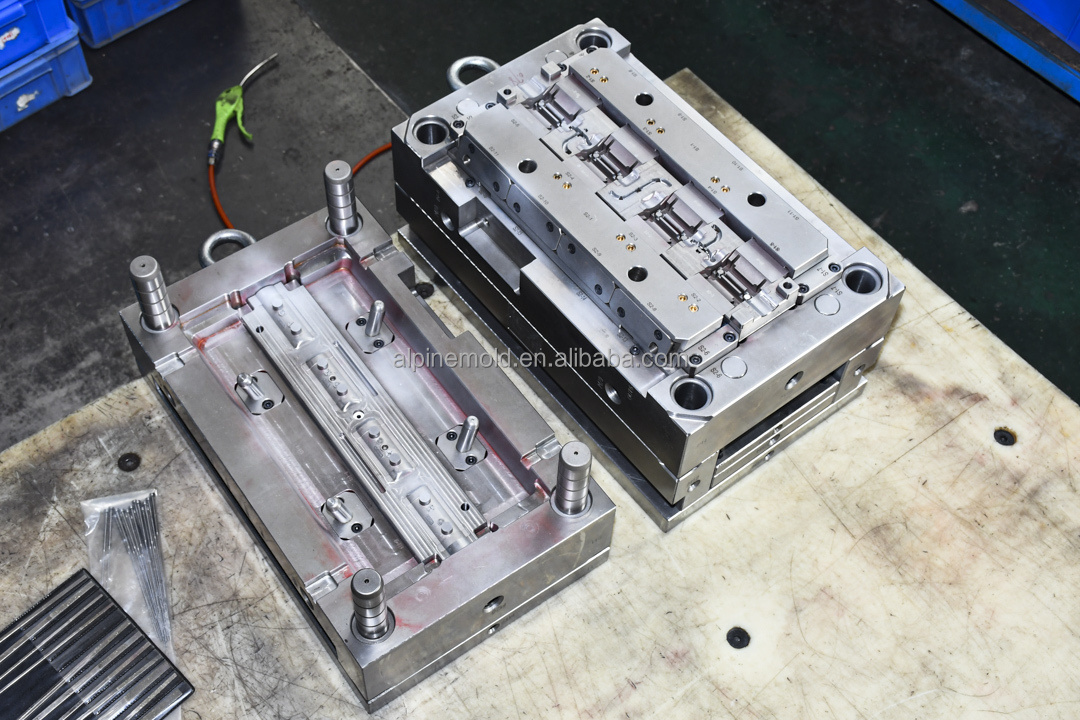

Products Show

Precision Molds

Shenzhen Alpine Mold Engineering Factory

Established in 2002, Shenzhen Alpine Mold Engineering Factory has more than 5,000 square meters area, as well as more than 100 staff who have at least 10 years working experience of making mold products exported to all over the world.

Alpine mold specializes in the development and manufacturing of plastic injection molds and parts, die casting molds and parts, CNC machining parts, silicone and rubber mold and products to the range of electronic products, automotive products, home appliances,medical device and so on.

Equipped with the most advanced software for designing, analyzing and manufacturing, Alpine Mold has imported a lot of high precision plastic injection parts mold machines from Taiwan and Japan, including High Speed CNC, Mirror EDM, Wire Cutting Machine, and CMM Inspection Machines and so on to guarantee high standard quality of all molds and products

Currently, we operate business in Europe, North America and other regions. And we take "customer - oriented, Quality first" as company`s aim, committed to provide clients with high quality products and overvalued services.

Equipped with the most advanced software for designing, analyzing and manufacturing, Alpine Mold has imported a lot of high precision plastic injection parts mold machines from Taiwan and Japan, including High Speed CNC, Mirror EDM, Wire Cutting Machine, and CMM Inspection Machines and so on to guarantee high standard quality of all molds and products

Currently, we operate business in Europe, North America and other regions. And we take "customer - oriented, Quality first" as company`s aim, committed to provide clients with high quality products and overvalued services.

Q1: Are you trading company or manufacturer ?

A: We are 100% direct factory, having our own's factory buildings and equipment.Welcome to visit us at any time.

Q2: How do you control the quality?

A: (1)Material inspection--Check the material surface and roughly dimension.

(2)Production first inspection--To ensure the critical dimension in mass production.

(3)Sampling inspection--Check the quality before sending to the warehouse.

(4)Pre-shipment inspection--100% inspected by QC assistants before shipment.

Q3: How about the lead time?

A : Generally, 1-2 weeks for samples, 3-4 weeks for mass production.

Q4: Can I get a quote without drawings?

A: Sure, we appreciate to receive your samples, pictures or drafts with detailed dimensions for accurate quotation.

Q5: Is it possible to know how are my products going on without visiting your company?

A: We will offer you DFM report and send weekly reports with digital pictures and videos which show the machining progress.

Q6: What is your payment terms?

A1: Mold Payment: 40% deposit by T/T in advance, 30% second mold payment before sending out the first trial samples, 30% mold balance after you agree the final samples.

A: We are 100% direct factory, having our own's factory buildings and equipment.Welcome to visit us at any time.

Q2: How do you control the quality?

A: (1)Material inspection--Check the material surface and roughly dimension.

(2)Production first inspection--To ensure the critical dimension in mass production.

(3)Sampling inspection--Check the quality before sending to the warehouse.

(4)Pre-shipment inspection--100% inspected by QC assistants before shipment.

Q3: How about the lead time?

A : Generally, 1-2 weeks for samples, 3-4 weeks for mass production.

Q4: Can I get a quote without drawings?

A: Sure, we appreciate to receive your samples, pictures or drafts with detailed dimensions for accurate quotation.

Q5: Is it possible to know how are my products going on without visiting your company?

A: We will offer you DFM report and send weekly reports with digital pictures and videos which show the machining progress.

Q6: What is your payment terms?

A1: Mold Payment: 40% deposit by T/T in advance, 30% second mold payment before sending out the first trial samples, 30% mold balance after you agree the final samples.

A2: Production Payment: 50% deposit in advance, 50% before sending out the final goods.

Hot Searches