- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

CY

-

Voltage:

-

220V, 50/60Hz

-

Power:

-

1200W

-

Dimension(L*W*H):

-

600*300*470mm

-

Applicable Industries:

-

Laboratory, Material Science

-

Weight (KG):

-

80

-

Product Name:

-

thermal evaporation coating machine

-

Keywords:

-

thermal evaporation coating

-

Chamber Material:

-

SS304

-

Spin Speed:

-

0-20rpm

-

Wafer Size:

-

<60mm

-

Vacuum System:

-

60L/s

-

Control:

-

PLC+ Touch Screen

-

Film Monitor:

-

Optional

-

Evaporation Source:

-

Molybdenum/Tungsten

-

Certification:

-

CE

Quick Details

-

Machine Type:

-

Laboratory Coating Machine, Coating Equipment

-

Marketing Type:

-

Hot Product 2024

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

CY

-

Voltage:

-

220V, 50/60Hz

-

Power:

-

1200W

-

Dimension(L*W*H):

-

600*300*470mm

-

Applicable Industries:

-

Laboratory, Material Science

-

Weight (KG):

-

80

-

Product Name:

-

thermal evaporation coating machine

-

Keywords:

-

thermal evaporation coating

-

Chamber Material:

-

SS304

-

Spin Speed:

-

0-20rpm

-

Wafer Size:

-

<60mm

-

Vacuum System:

-

60L/s

-

Control:

-

PLC+ Touch Screen

-

Film Monitor:

-

Optional

-

Evaporation Source:

-

Molybdenum/Tungsten

-

Certification:

-

CE

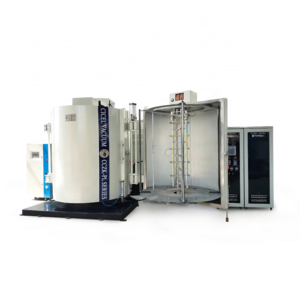

1800C thermal evaporation coating machine for metal film deposition on wafer

OVERVIEW--THERMAL EVAPORATION

Thermal evaporation is a popular physical vapor deposition technique because of its simplicity. During this process, a material in a high-vacuum environment is heated to its evaporation point by joule heating of the resistive boat in which it is located. The vaporized molecules then travel from the source to the substrate where they nucleate together, forming a thin film coating. A wide variety of materials can be deposited using this technique such as aluminum, silver, nickel, chrome, magnesium, among many others.

Features of thermal evaporation coater:

1. This is a desk evaporation coating machine. The evaporation temperature is from 200

ºC

to 1700

ºC

, using tungsten wire basket as evaporation source.

2. The evaporation source coat is high purity alumina crucible. The distance between sample stage and evaporation source is adjustable.

3. The device has a high precision temperature control system, using the cycle heating method, can stably evaporate metal and some organic matter.

4. Using high purity quartz cavity as vacuum chamber, coating process can be seen completely.

5. The instrument is equipped with bipolar rotary vane vacuum pump, which can quickly reach the vacuum degree of 1.0E-1pa and meet the vacuum environment required by most evaporation and coating experiments.

This instrument is suitable for evaporation and coating most of the metal and some organic materials film. It has compact structure and small size, which is a cost-effective laboratory coating equipment.

Specifications of thermal evaporation coater:

|

Product Name |

Thermal evaporation coater |

|

Evaporation System |

1. Evaporation voltage:10V 2. Evaporation current: 0 to 100A, adjustable 3. Evaporation source: two Molibden boat for Zns , with baffle 4. Sample table size:φ100mm 5. Vacuum chamber:stainless steel, 245*300mm 6. Quartz observation window with baffle, φ60mm 7. The air pumping interface of the vacuum chamber is KF40 8. Air intake interface is 1/4 inch double ferrule joint 9.PLC+ 7-inch touch screen 10. Safety protection: over current, low vacuum 11. Ultimate vacuum: 5.0E*10-5Pa(with molecular pump system) 12. Max. Temperature 1800℃ 13. Size: 650*600*1000mm |

|

Vacuum S ystem |

Backup pump: rotary vane vacuum pump, 1.1L/s Molecular pump: TG60FR OSAKA turbo, 60L/s Vacuum measurement: Composite vacuum gauge Measuring range: 10-5Pa ~105Pa |

|

Film Thickness M onitor |

a) Quantity: 1 set single-channel film thickness monitor b) Film thickness resolution:0.0136Å(aluminum) c) Measuring range : 0~ 500,000 Å ( aluminum ) d) Accuracy of film thickness :±0.5% e) Measuring speed:100mS~1S/T(setting as request) f) Crystal frequency : 6MHz g) M ounting flange:CF35 h) Communication interface : RS-232/485 serial interface |

1. W e have thermal evaporation coater with 1/2/3/4/6/8... evaporation source

2. Standard is tungsten, other material evaporation source is customizable

3. Chamber material: high purity quartz or SUS304

4. Different vacuum system is optional

5. Film thickness monitor is optional