- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

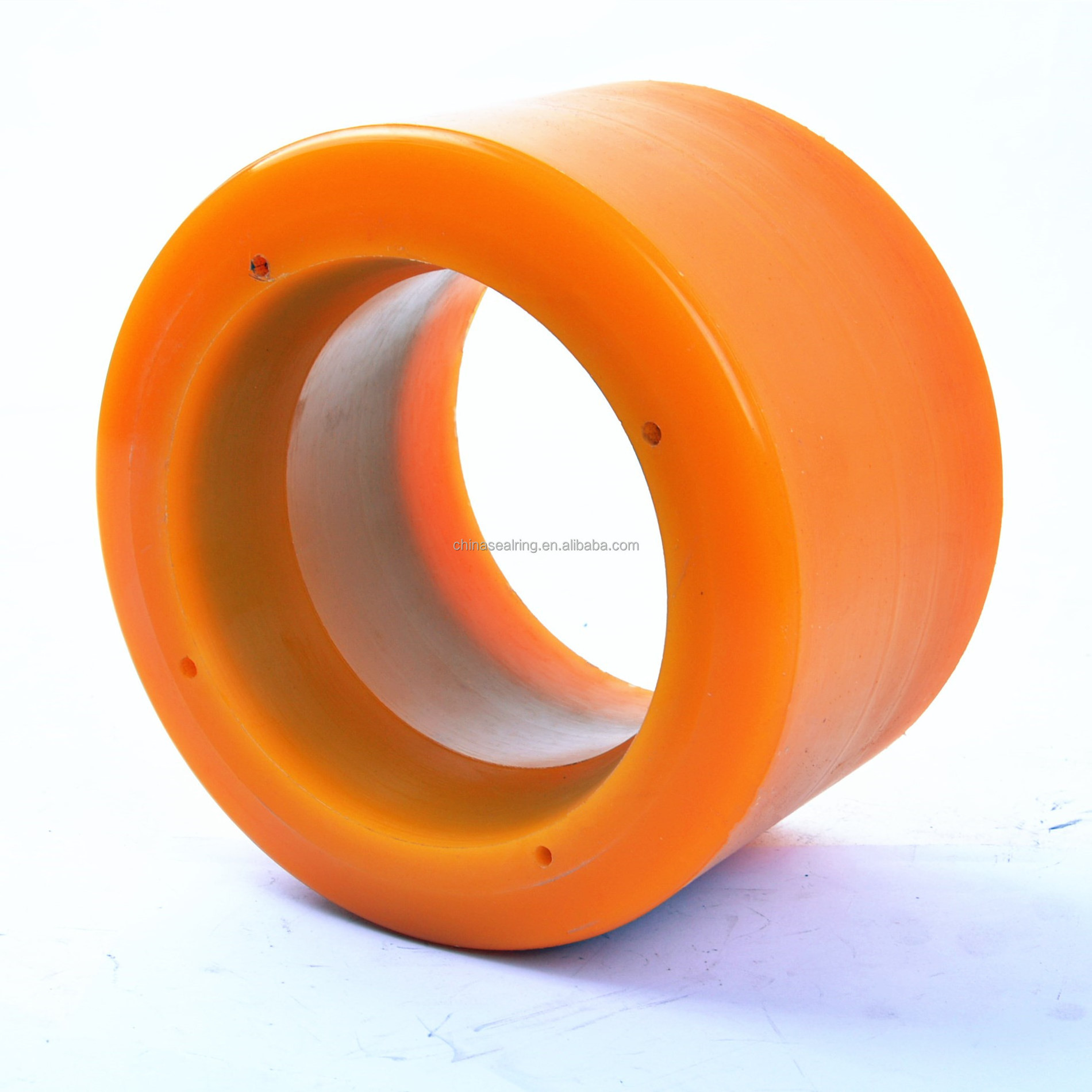

FEB040

-

Material:

-

Pu/Polyurethane

-

Color:

-

yellow /Brown/Red

-

Certification:

-

ISO9001

-

Function:

-

Horizontal

-

Drawing Format:

-

DWG/CAD/PDF

-

Shape:

-

Round Shape

-

Feature:

-

Anti-aging

-

Hardness:

-

30-90 Shore

-

Temperature:

-

40~120

-

OEM:

-

Accpetable

Quick Details

-

Processing Service:

-

Moulding

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

Sanshi

-

Model Number:

-

FEB040

-

Material:

-

Pu/Polyurethane

-

Color:

-

yellow /Brown/Red

-

Certification:

-

ISO9001

-

Function:

-

Horizontal

-

Drawing Format:

-

DWG/CAD/PDF

-

Shape:

-

Round Shape

-

Feature:

-

Anti-aging

-

Hardness:

-

30-90 Shore

-

Temperature:

-

40~120

-

OEM:

-

Accpetable

Products Description

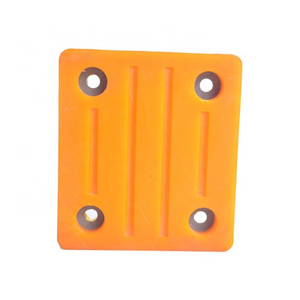

High Temperature Resistant Plastic/PU Parts Customized Injection Molding Parts

The Polyurethane (PU) Sheets are made from raw materials of best quality which certifies durability at its user end. Polyurethane sheet is popular for a wide range of industrial applications including linings, scrapers, gaskets and machined components.

The PU sheets can be produced with aluminum, paper, or nude. Additionally, its temperature can range from 30°C to +80°C.

Sanshi factory PU Sheets comprise of an excellent anti-abrasion and highly elasticity, each consist of different thickness and sizes. The main function of each PU sheet is to reduce pressure. They are widely used as Cushion, Anti-Pressing and Heavy Load parts.

All Polyurethane products are applicable for variety of uses. More than seventy five percent of the worldwide utilization of

polyurethane items is in the form of foams, with flexible and rigid types which are roughly equal in market size.

Sanshi factory PU Sheets comprise of an excellent anti-abrasion and highly elasticity, each consist of different thickness and sizes. The main function of each PU sheet is to reduce pressure. They are widely used as Cushion, Anti-Pressing and Heavy Load parts.

All Polyurethane products are applicable for variety of uses. More than seventy five percent of the worldwide utilization of

polyurethane items is in the form of foams, with flexible and rigid types which are roughly equal in market size.

|

tem

|

Plastic injection moulding parts

|

Plastic material

|

ABS,PP,Nylon,PC or any other material as you need

|

|

Type of enterprise

|

Professional manufacturer of injection molds and injection molding parts

|

Service

|

OEM,Design based on your idea or Make mold and produce based on your drawing

|

|

Design software

|

Solidworks, Pro-E, UG, CAD, Rhino etc.

|

Drawing format

|

Step, Igs, PDF, CAD etc.

|

|

Produce Size

|

From small to big, based on your drawing or sample

|

Product weight

|

1g-10kgs

|

|

MOQ

|

100PCS

|

Production ability

|

10,000pcs/day

|

|

Assembly & Test

|

Professional assembly factory with 6 assembly lines

|

Package

|

Standard carton, pallet or customized package

|

|

Payment details

|

T/T, L/C, D/A, D/P, Western Union, MoneyGram, Veem, Paypal etc

|

Delivery time

|

For mold & samples: 3-4 weeks.

For mass production: 15 workdays |

|

Shipping way

|

By Courier DHL, Fedex, TNT, UPS, EMS, By Sea or By Air

|

Prototype

|

3D printing, CNC, Laser cutting etc

|

Product packaging

Paper bag, PP bag, Carton or pallet, Customized packing accepted

Hot Searches