- Product Details

- {{item.text}}

Quick Details

-

Warranty:

-

1 year

-

Brand Name:

-

YH

-

Model Number:

-

SL-V50

-

Place of Origin:

-

Shanghai, China

-

Horsepower:

-

50hp

-

Power:

-

50hz/60hz

-

motor:

-

Siemens

Quick Details

-

Application:

-

Automotive Industry, Industrial Utilities, Metal and Equipment Manufacturers

-

Pressure:

-

Ultra High Pressure 420MPA

-

Voltage:

-

380v/220v

-

Warranty:

-

1 year

-

Brand Name:

-

YH

-

Model Number:

-

SL-V50

-

Place of Origin:

-

Shanghai, China

-

Horsepower:

-

50hp

-

Power:

-

50hz/60hz

-

motor:

-

Siemens

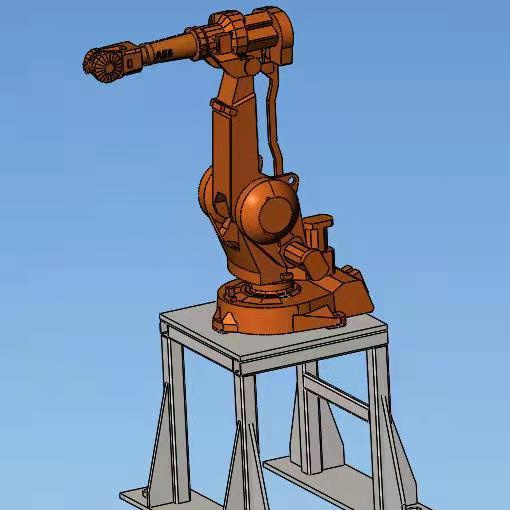

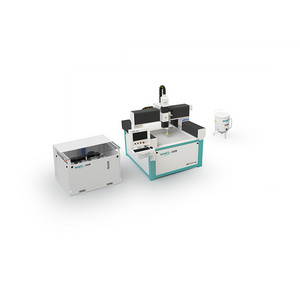

Hot project--- Robot waterjet cutting machine

Different robot waterjet--pure waterjet and abrasive waterjet are all available.

Products Description

Delivery and Service

Along with the most reliable, high-precision waterjet parts in the industry, Shanghai Yuanhong Waterjet provides first-class

customer support.

Our service team is highly trained certified technicians that provide troubleshooting, field service, and training. We are here to

answer any questions you may have regarding your waterjet. Our highly experienced staff will make sure we get the right part sent out within 3 days to make sure production is up and running for maximum productivity.

* 3-days shipping on most items,

15-days for high pressure pump, H2O pump is available always.

22 working days for cnc waterjet machine.

* Prompt Technical Support

* First-Class Customer Service

Tell us your consumable part needs and we will keep the products in stock for you and no additional charge! If there is a part we don’t have in stock, we will drop-ship it straight to you!

* First-Class Customer Service

Tell us your consumable part needs and we will keep the products in stock for you and no additional charge! If there is a part we don’t have in stock, we will drop-ship it straight to you!

Yuanhong Waterjet JTELINE-50

Smart Design Advances

* Longer Run-times – Significant advances were achieved by eliminating some seals and changing materials.

* Faster Cutting – Rather than just increase the pressure, we changed and strengthened the machine design to produce 60,000 psi for faster cutting and cleaner edges.

Our full-featured, SL-V50 pumps are available in more sizes and with new “Cutting” options available .

These pumps are the easiest to maintain and the most advanced pumps ever offered. Seals last over 1,000 hours,

depending on pressure and water quality – longer than any other system – for continuous operation for the most demanding production schedules.

Easiest to Maintain

* Single Intensifier per Pump – 60,000 psi is produced with just one intensifier, delivering lower maintenance costs, and quieter operation with fewer parts.

* Larger Plunger – The longer, slower strokes of the ceramic plunger move more water with each stroke, providing more up time and longer seal life.

* “Quick Release” Plunger –Exclusive plunger removal design simplifies removal. Cartridge seal system design is the fastest change-out design and provides a redundant sealing system.

Most Intelligently Designed System

* High Tech Software –Standard system includes plunger location control (plunger can be moved to a specific side to facilitate maintenance), system capacity utilization (to show if it is stroking at the maximum rate), hours of operation (for either side, if redundant option is installed), and more.

* Lower Noise Levels – The pump were designed to operate below 77.5 dB(A), improving the environment for workers.

* See-through Top Covers – Inspection of the intensifier can be done by looking through the top cover. In addition, both sides can be open at the same time, allowing easier access.

* Dual Pressure Control – Pumps are equipped for a high and a low setting. Ideal for brittle materials, the low setting is used for piercing and the high setting for cutting. For even more versatility, check out the Proportional Control option under "Options".

* Threaded End Cap Retainers – End caps, high pressure cylinder and hydraulic cylinder are all threaded together, simplifying access to the seals. In addition, each side of the intensifier can be disassembled independently of the other.

* Booster Pump Protection –Sensors before and after the booster pump assure that the flow of water is continual and adequate. An important feature to protect your system.

Sophisticated Software

* Touch Control Panel – Rapid programming and troubleshooting.

* Upgrade able Communications – Remote access and networking of multiple pumps are options which represent huge potential for

creating new opportunities.

* Multiple Language, Dual Pressure Control and many more standard features.

* Longer Run-times – Significant advances were achieved by eliminating some seals and changing materials.

* Faster Cutting – Rather than just increase the pressure, we changed and strengthened the machine design to produce 60,000 psi for faster cutting and cleaner edges.

Our full-featured, SL-V50 pumps are available in more sizes and with new “Cutting” options available .

These pumps are the easiest to maintain and the most advanced pumps ever offered. Seals last over 1,000 hours,

depending on pressure and water quality – longer than any other system – for continuous operation for the most demanding production schedules.

Easiest to Maintain

* Single Intensifier per Pump – 60,000 psi is produced with just one intensifier, delivering lower maintenance costs, and quieter operation with fewer parts.

* Larger Plunger – The longer, slower strokes of the ceramic plunger move more water with each stroke, providing more up time and longer seal life.

* “Quick Release” Plunger –Exclusive plunger removal design simplifies removal. Cartridge seal system design is the fastest change-out design and provides a redundant sealing system.

Most Intelligently Designed System

* High Tech Software –Standard system includes plunger location control (plunger can be moved to a specific side to facilitate maintenance), system capacity utilization (to show if it is stroking at the maximum rate), hours of operation (for either side, if redundant option is installed), and more.

* Lower Noise Levels – The pump were designed to operate below 77.5 dB(A), improving the environment for workers.

* See-through Top Covers – Inspection of the intensifier can be done by looking through the top cover. In addition, both sides can be open at the same time, allowing easier access.

* Dual Pressure Control – Pumps are equipped for a high and a low setting. Ideal for brittle materials, the low setting is used for piercing and the high setting for cutting. For even more versatility, check out the Proportional Control option under "Options".

* Threaded End Cap Retainers – End caps, high pressure cylinder and hydraulic cylinder are all threaded together, simplifying access to the seals. In addition, each side of the intensifier can be disassembled independently of the other.

* Booster Pump Protection –Sensors before and after the booster pump assure that the flow of water is continual and adequate. An important feature to protect your system.

Sophisticated Software

* Touch Control Panel – Rapid programming and troubleshooting.

* Upgrade able Communications – Remote access and networking of multiple pumps are options which represent huge potential for

creating new opportunities.

* Multiple Language, Dual Pressure Control and many more standard features.

|

Item

|

Description

|

|

High-pressure pump is characterized

|

|

|

1

|

Nominal power

|

37 kW / 50 HP

|

•Hydraulic pump of variable flow and compensated pressure

|

|

|

2

|

Maximum working pressure

|

60,000 psi 4200bar

|

•High / low pressure selection that allows piercing

|

|

|

3

|

Voltage

|

380V 50hz, or 220v 400-460V 60HZ

|

•Electrical inversion of the cutting head

|

|

|

|

Intensifier Assembly Quantity

|

1 sets

|

|

|

|

4

|

Maximum flow

|

1.0 Gallon

3.8L

|

•Leakage detection in de high-pressure circuit

|

|

|

6

|

Pressure accumulator volume

|

1.0 L

|

•System to uninstall de piston without uninstalling the cylinder

|

|

|

7

|

Max. Orifice

|

0.014" (0.036mm)

|

|

|

|

10

|

Length x Width x Height

(MM)

|

1,700*914*1,453mm

|

•The sensors, located before and after the booster pump

|

|

|

11

|

Weight (kg)

|

1350kg

|

•Maintenance-free Operation

|

|

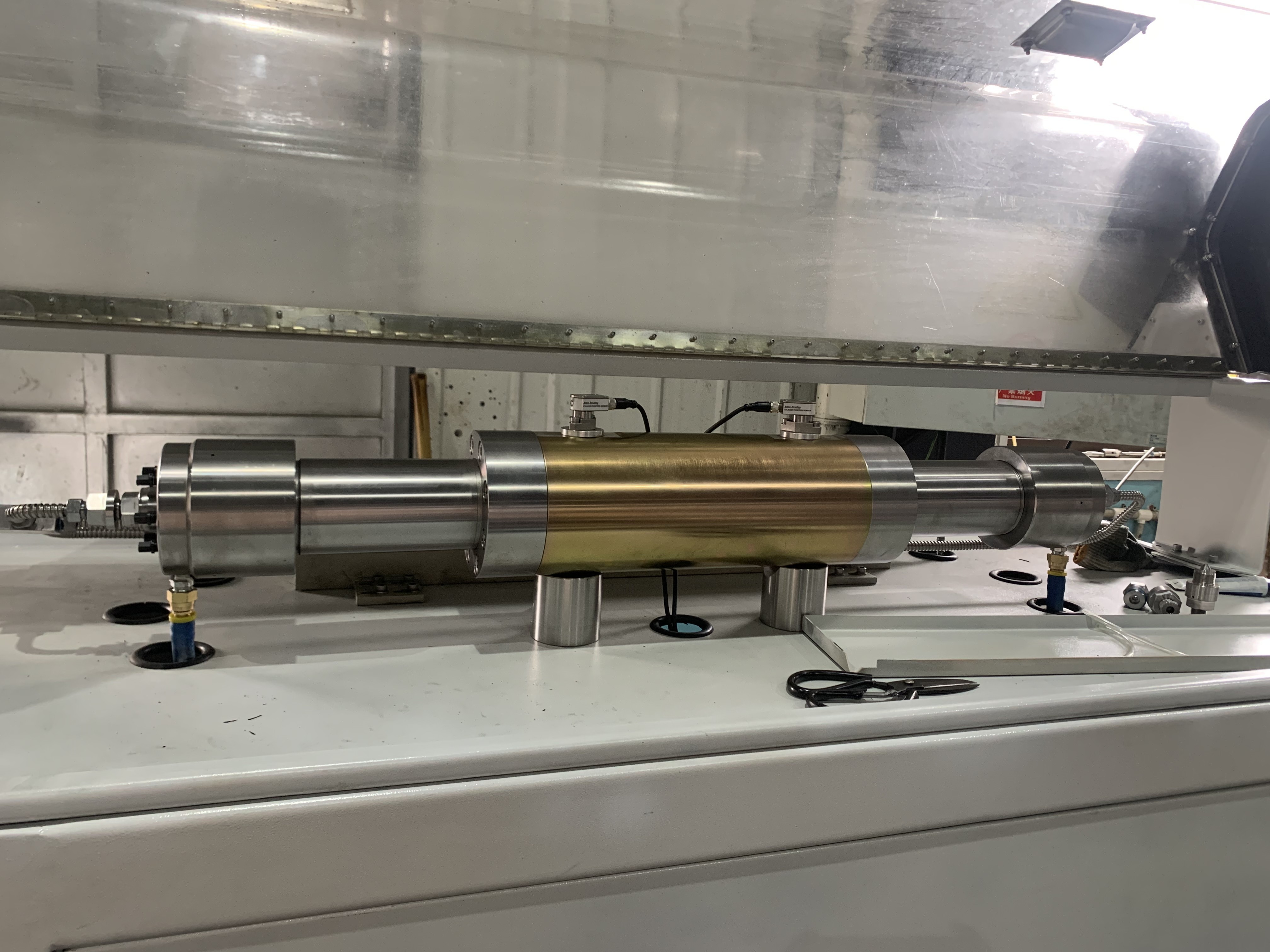

Intensifier assembly 60000psi

Heart of the high pressure pump

Waterjet Attenuator

Maintenance-free

attenuator 1.0L

Projects

Waterjet intensifier pump and waterjet direct drive pump are the two main types of waterjet pump.

Stable pressure outlet, and good hydraulic system, oil cycle system is its strength.

If you need ,air cooling system can be added if you need.

Similar Products

7XD-60 Double intensifier pump

7XR-50 Redundant intensifier pump; This

waterjet pump has two intensifier systems. If one of the intensifier systems fails or requires service, the second intensifier system can continue operations until the intensifier pump can be shut down for service.

20XD-87K 87K PSI/ 600MPA waterjet high pressure pump, fast cutting speed, and work performance.

And there are direct drive pump for waterjet industry. Also the high pressure waterjet pump 94,000psi is available . Please let us know for more information if you have any needs.

We can customize different pump for you if you need any changes.

Compare waterjet Intensifier pump and direct drive Pump.

Please refer to this paper.

https://www.yhwaterjet.com/info/waterjet-pump-yhwaterjet-tell-you-more-64843667.html

Hot Searches