- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Guanghe

-

Voltage:

-

220V

-

Dimension(L*W*H):

-

4500*1500*3000

-

Weight:

-

300 KG

-

Name:

-

Corn Stripping Machine

-

Production capacity:

-

15t/H

-

Main motor:

-

18.5 kW class 6

-

Winch motor:

-

2.2 kW class 6

-

Driven sieve motor:

-

2.2 kW class 6

-

Thresher size:

-

4.5m long * 1.5m wide * 3m high

-

Corn cob bin size:

-

L2.8m*W1.8m

-

Spindle speed:

-

350 revolutions per minute

-

Spindle length:

-

2 metres

-

Bucket diameter:

-

80CM

Quick Details

-

Type:

-

Farm Machine

-

Use:

-

Rice Thresher

-

Production Capacity:

-

1500kg/h

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Guanghe

-

Voltage:

-

220V

-

Dimension(L*W*H):

-

4500*1500*3000

-

Weight:

-

300 KG

-

Name:

-

Corn Stripping Machine

-

Production capacity:

-

15t/H

-

Main motor:

-

18.5 kW class 6

-

Winch motor:

-

2.2 kW class 6

-

Driven sieve motor:

-

2.2 kW class 6

-

Thresher size:

-

4.5m long * 1.5m wide * 3m high

-

Corn cob bin size:

-

L2.8m*W1.8m

-

Spindle speed:

-

350 revolutions per minute

-

Spindle length:

-

2 metres

-

Bucket diameter:

-

80CM

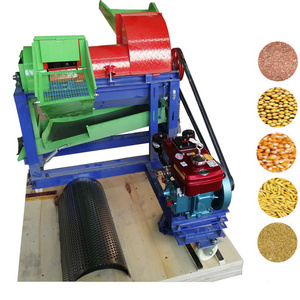

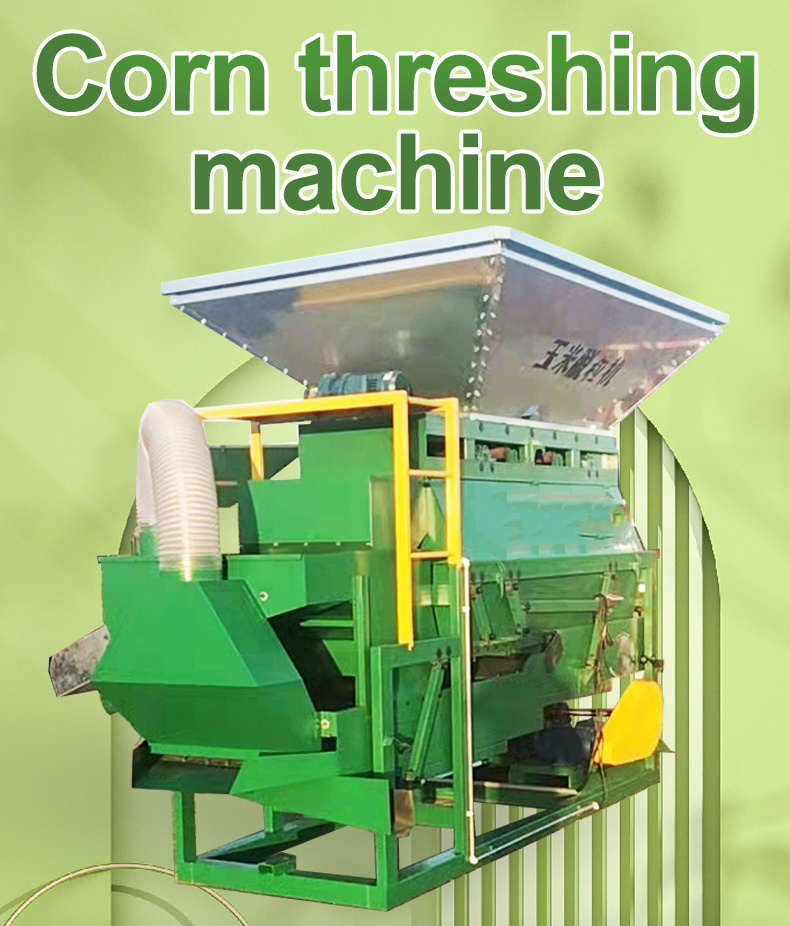

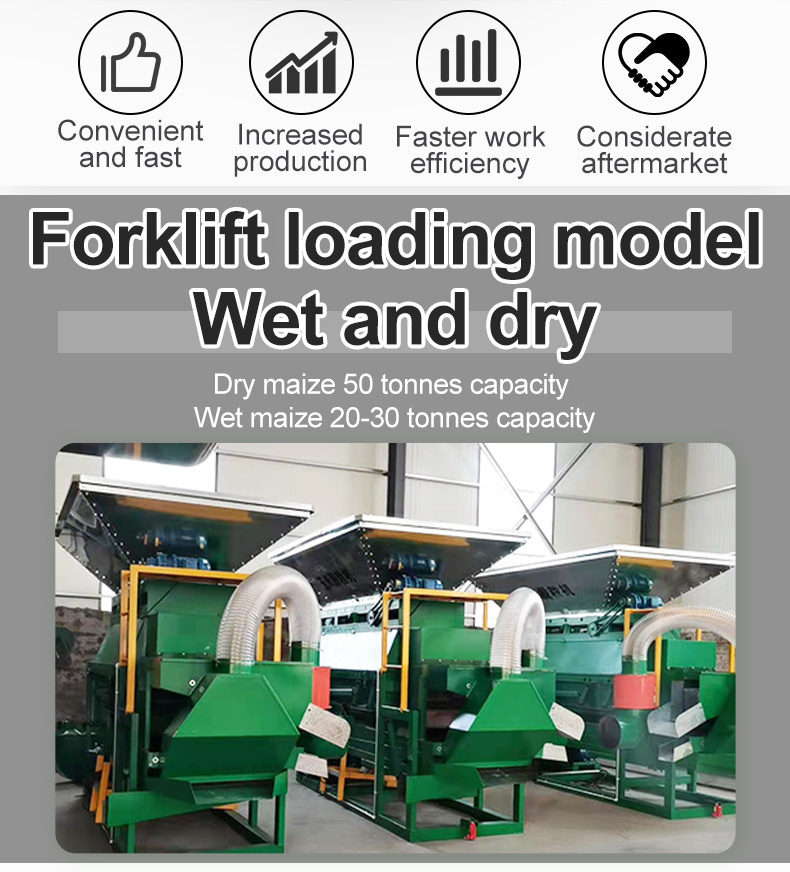

Excellent quality Corn Threshing machine mini big corn diesel operated rice wheat thresher machine

The main power unit of the corn thresher is the motor, which drives the threshing drum and the fan through the rotation of the motor, and can realise the working requirements of corn threshing, screening, removing impurities and collecting. Under the continuous optimisation of mechanical structure, the corn thresher models produced at this stage are more compact and integrated, and functionally rich and reasonable, effectively achieving high efficiency and low energy consumption, and saving space, convenient to use.

Product Description

After harvesting, the corn can be threshed by manpower with the conveyor belt to achieve feeding, the feeding inlet is located in the upper part of the machine, after feeding the corn into the threshing chamber, due to the rotor and drum rotating impact, the kernels will be peeled off in turn, the current stage of the threshing machine mostly adopts a number of times threshing to ensure that the kernels of the threshing rate. After threshing, the corn kernels are separated by the sieve holes, and the remaining debris such as corn husk and corn silk are discharged under the action of the blower, and the kernels can be collected automatically.

Products Description

The function of corn thresher is to thresh the corn cobs after drying. Most of them are axial drum type, and there are also vertical threshing disc type. Because it has high production efficiency, good threshing quality, easy operation, simple structure, sturdy and durable.

Corn thresher is mainly composed of drum, concave plate, sieve, fan, feeding hopper, seed skid plate, spiral guide bar and so on. It adopts the axial flow threshing device that tangentially feeds the cob discharge shaft at the end of the shaft.

Specification

|

Name

|

Corn Stripping Machine

|

|

Production capacity

|

15t/H

|

|

Main motor

|

18.5 kW class 6

|

|

Winch motor

|

2.2 kW class 6

|

|

Driven sieve motor

|

2.2 kW class 6

|

|

Thresher size

|

4.5m long * 1.5m wide * 3m high

|

|

Corn cob bin size

|

L2.8m*W1.8m

|

|

Spindle speed

|

350 revolutions per minute

|

|

Spindle length

|

2 metres

|

|

Bucket diameter

|

80CM

|

Details Images

Hot Searches