- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

RZ

-

Viscosity:

-

standard

-

Product name:

-

Bearing raceway grinding wheel

-

Material:

-

Corundum

-

Usage:

-

bearing ring

-

Size:

-

41mmx 38mm x 13mm

-

Advantage:

-

High Working Efficiency

-

Bond:

-

Vitrified

-

Keyword:

-

Abrasive Grinding Wheels

-

Packing:

-

Carton Box

Quick Details

-

Application:

-

Aluminum, Deburring

-

Shape:

-

Cup-Shaped

-

Hardness:

-

standard

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

RZ

-

Viscosity:

-

standard

-

Product name:

-

Bearing raceway grinding wheel

-

Material:

-

Corundum

-

Usage:

-

bearing ring

-

Size:

-

41mmx 38mm x 13mm

-

Advantage:

-

High Working Efficiency

-

Bond:

-

Vitrified

-

Keyword:

-

Abrasive Grinding Wheels

-

Packing:

-

Carton Box

Related Products

Products Description

Bearing is an important basic parts of all kinds of mechanical equipment, mainly used in metallurgy, wind power, mining machinery, aerospace, automotive parts and so on.

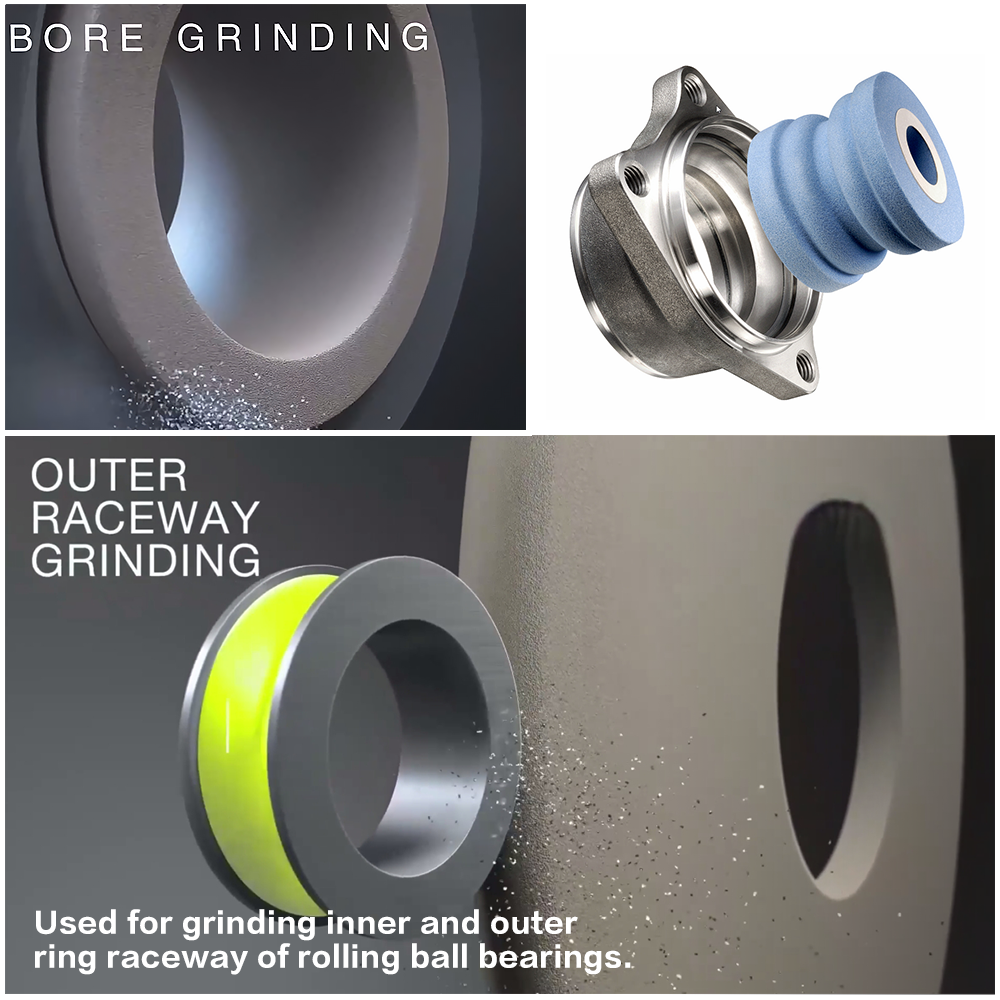

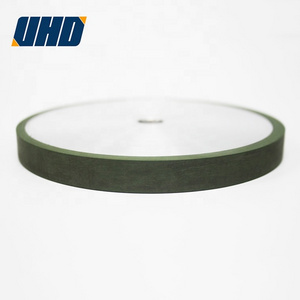

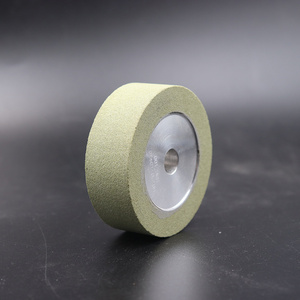

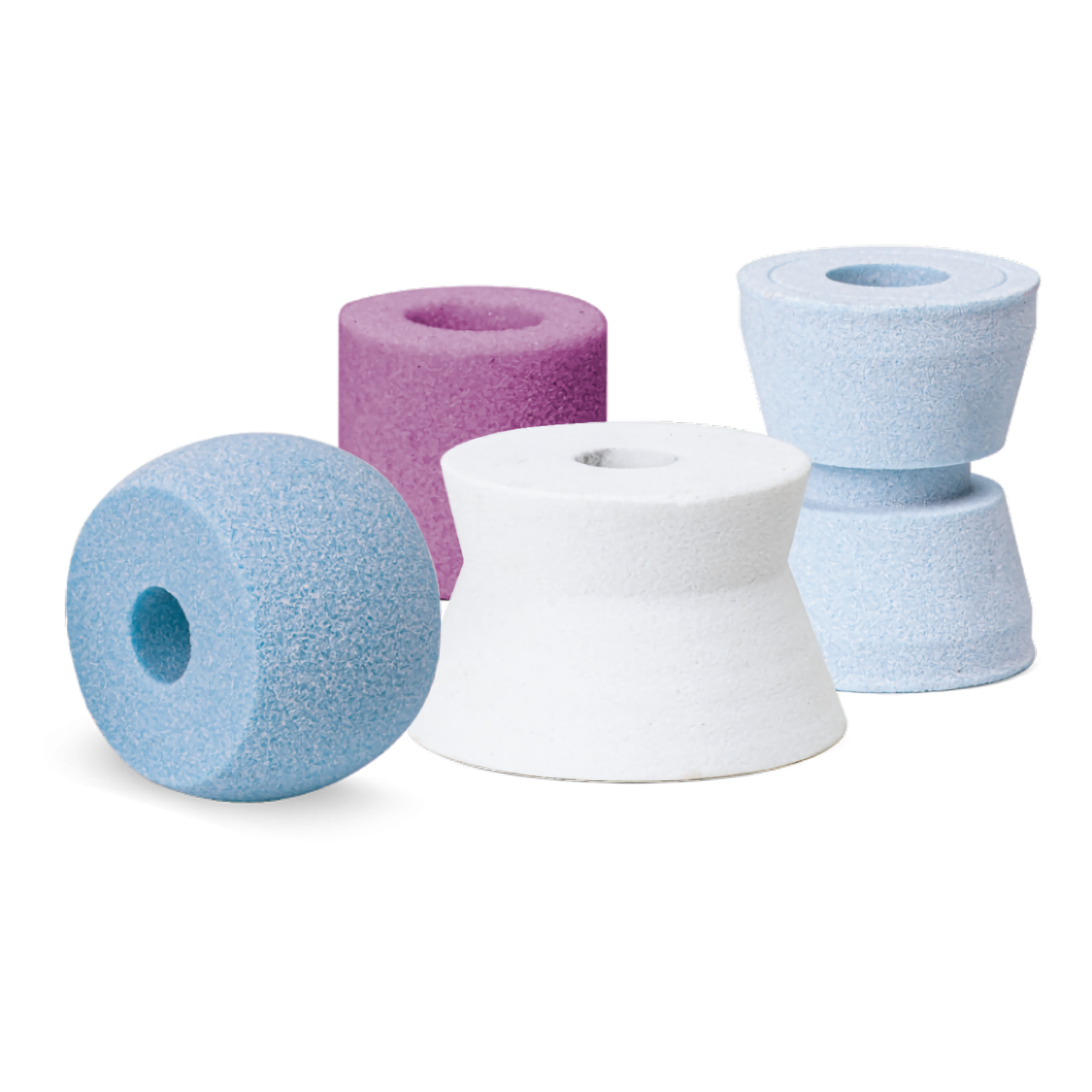

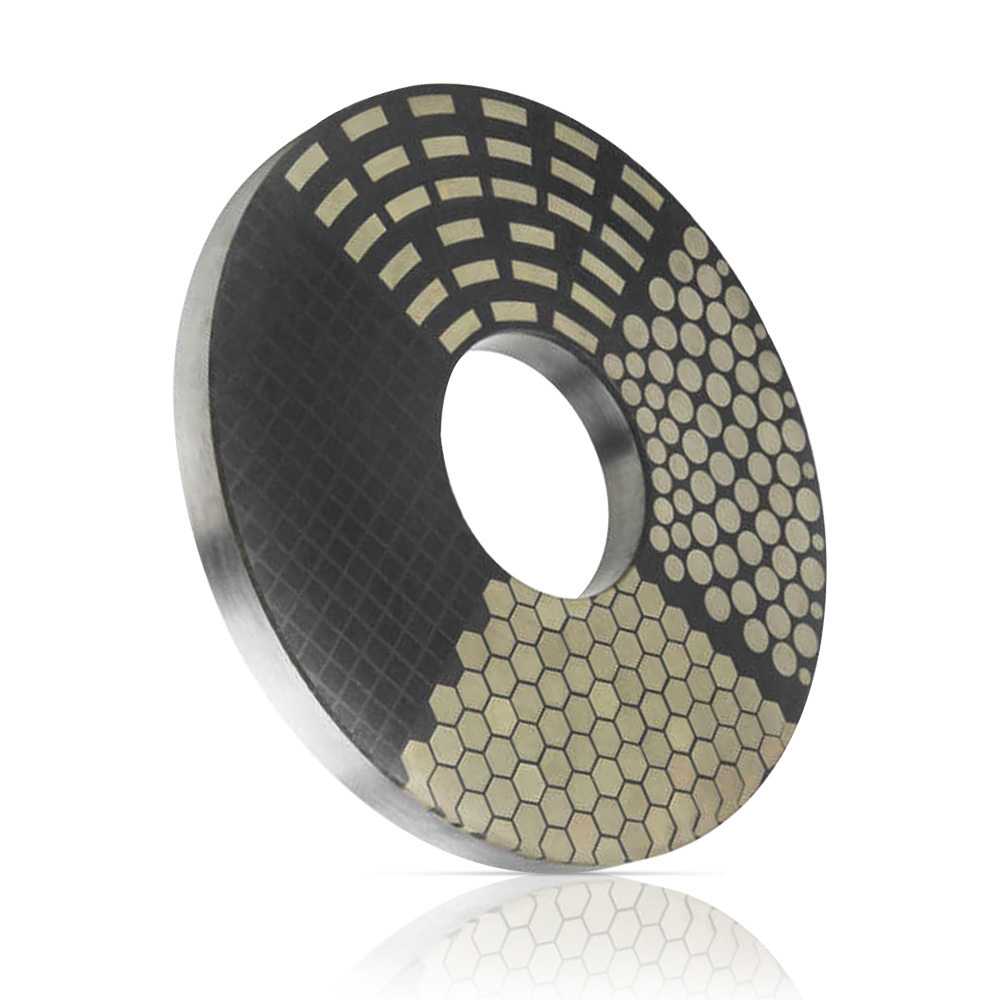

Bearing Raceway Grinding Wheel

Our abrasive solutions have improved the efficiency, quality and cost of manufacturing bearings. There are many types of grinding wheel applications that go into manufacturing bearings. The Centerless grinding wheel for the Outer Ring. For Balls of the bearing RUIZUAN uses the Ball lapping wheels Ballz. The Inner Ring section of the bearing are grinded by RUIZUAN outer dimensional and inner dimensional ceramic grinding wheels. The high quality surface finish of the bearing is provided by the RUIZUAN Super Finishing Stones which are applied to inner and outer ring of the bearing.

|

PART TYPE /MATERIAL:

|

Outer bearing ring / 100Cr6 hard treated HRc 62

|

|

PART DIMENSIONS (MM):

|

65 x 50

|

|

STOCK REMOVAL (MM):

|

0.4 on radius

|

|

WHEEL DIMENSIONS (MM):

|

41 x 38 x 13

|

|

PART TYPE /MATERIAL:

|

Inner bearing ring bore / 100Cr6 HRc 48

|

|

PART DIMENSIONS (MM):

|

65 x 50

|

|

STOCK REMOVAL (MM):

|

0.4 on radius

|

|

WHEEL DIMENSIONS (MM):

|

40 x 40 x 13

|

1.Reduced Cycle Times Our self-sharpening grain technology increases Material Removal Rates and reduces the need for dressing, cutting down on overall cycle times and effective cost per part.

2.Improved Geometric Consistency The innovative grain technology creates a product with unparalleled sharpness and cutting efficiency that reduces spindle power requirements even at increased Material Removal Rates. This means less mechanical stress and improved part geometry.

3.Improved Wheel Life The new grain micro-structure allows longer, cooler cuts and more stable profiles and shapes. Lowering the dress requirement significantly improves the wheel life without sacrificing work piece quality.

4.Improved Surface Finish

Used for grinding inner and outer ring raceway of rolling ball bearings.

Why Choose Us

International Leading Trade Fair

for Grinding Technology

for Grinding Technology

Hot Searches