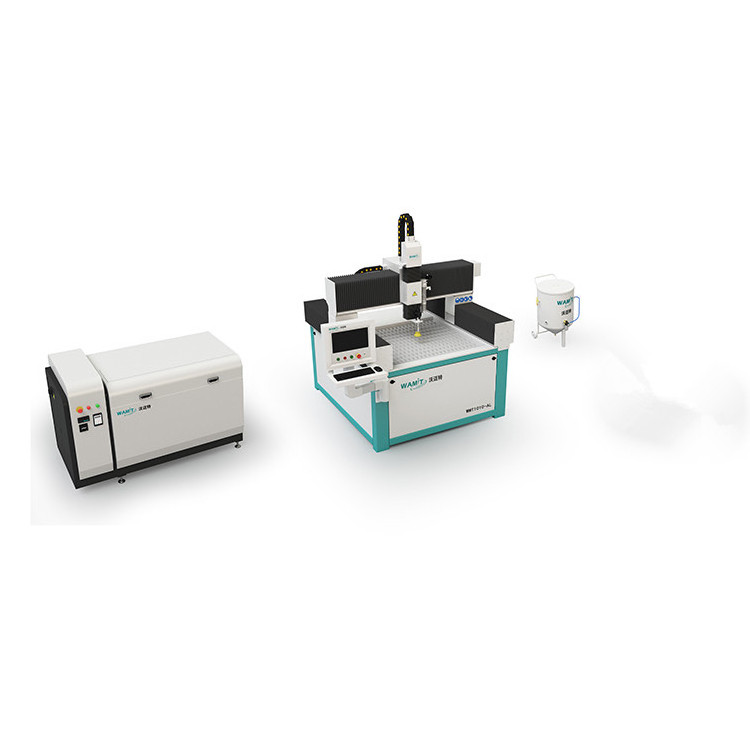

2.Pressure conversion methods: can save energy about 35%

3.cutting efficiency: greatly improved by 10%-20%

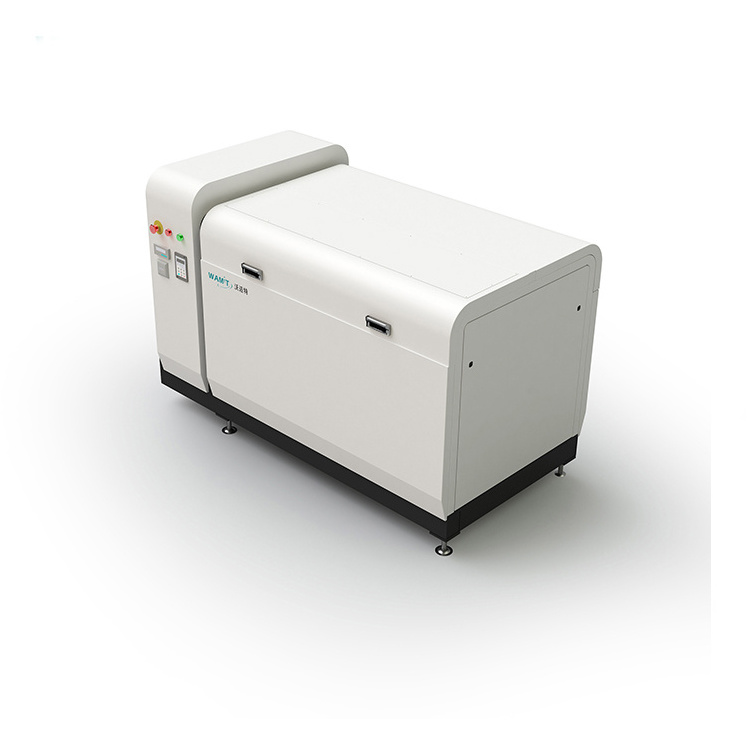

Displacement: 3.0 l/min.

Inlet pressure: 0.4MPa.

Main motor power: 15KW.

Dimensions: 1680*900*1100mm

Double row water filtration system (5Micron, 1micron, series)

Intelligent start and stop function.

Over-pressure automatic shutdown and under-pressure automatic protection.