- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

AY001

-

Product:

-

Custom overmolding injection plastic injection parts

-

Application:

-

Various molds

-

Mould material:

-

P20/718/738/NAK80/S136

-

Runner System:

-

Cold/ Hot Runner

-

Precision:

-

± 0.01mm

-

Machine:

-

injection molding machine

-

Certification:

-

ISO9001

-

Keyword:

-

injection plastic molding

-

Lead Time:

-

15-35 Days

-

Process type:

-

overmolding

Quick Details

-

Processing Service:

-

Moulding

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

OEM

-

Model Number:

-

AY001

-

Product:

-

Custom overmolding injection plastic injection parts

-

Application:

-

Various molds

-

Mould material:

-

P20/718/738/NAK80/S136

-

Runner System:

-

Cold/ Hot Runner

-

Precision:

-

± 0.01mm

-

Machine:

-

injection molding machine

-

Certification:

-

ISO9001

-

Keyword:

-

injection plastic molding

-

Lead Time:

-

15-35 Days

-

Process type:

-

overmolding

Different kinds of plastic parts mold can customized for you. Just Provide us with the following information:

1. The drawing of the plastic parts;

2.Material of the product and quantity;

3.Product Surface requirement;

4.Mold Requirement;

If you need more details, please contact us directly: Tel / Whats App: +8613510206811

Contact Person: Melody

Product Description

|

Product Description

|

Top Quality Plastic Custom Rubber TPE / TPR Overmolding Injection Mould

|

|

Standard

|

ISO9001:2015

|

|

Quality

|

RoSH and SGS standard

|

|

Size

|

According to your 2D, 3D Drawing.

|

|

Mould Base

|

SD/LKM Standard/HASCO Standard Self-made

|

|

Design & Program Softwares

|

CAD, CAM, CAE, Pro-E, UG, Soild works, Moldflow, CATIA....etc.

|

|

Need to provide

|

2D, 3D, samples, or the size of the multi-angle pictures

|

|

GateType

|

Pinpoint Gate, Edge Gate, Sub Gate, Film Gate, Valve Gate, Open Gate

|

|

Experience

|

12 years experience in plastic injection mold making and plastic prouducts produce.

|

|

Plastic Materials

|

PS, ABS, PP, PVC, PMMA, PBT, PC, POM, PA66, PA6, PBT+GF, PC/ABS, PEEK, HDPE, TPU, PET, PPO,...etc.

|

|

Equipments

|

CNC、EDM、Cutting Off Machine、Plastic Machinery etc.

|

Detailed Images

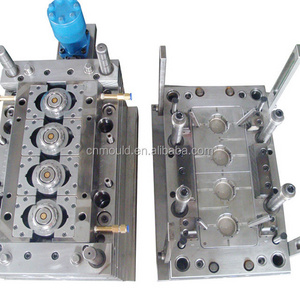

Overmolding process:

Rubber (soft plastic):TPE / TPR

Hard plastic: ABS/PP

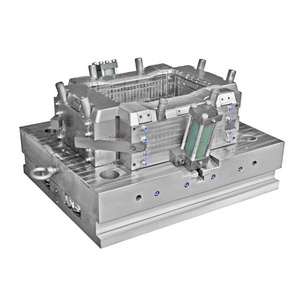

Mold Cavity can customized according to your requirement:

One cavity mold:

Multiple

cavity mold:

Switch Gate mold:

(Different shape and size mold can be make into one mold, just adopt switch gate.In this way, can save your mold cost.)

Different kinds of injection parts samples can do it for you:

Roduction Process

Factory Workshop:

Company Introduction

Plastic Injection Mould making:

1.Samples/Drawing &Requirement from you

2.Mold design:we will Communicate and Exchange the opinion with you after you place order.

3.Material Purchase:Steel cutting and mould base tooling.

4.Assembling.

5.Inspection of mould : following and controlling the tooling processing.

6.Mold testing:We will inform you the date.Than will send the sample's inspection report&injection parameters with the sample to you!

7.Your instruction &confirmation for shipment.

8.Ready made mould before packing.

9.We provide any differeny kinds of plastic injection mould, blow mould, silicone mould, die casting mould service.

Plastic molding Specification :

1. Professional manufacturer,design,production injection mould and stamping mould quality control

2. rich export experience plastic injection mould and stamping mould

3. Reasonable price of design mould

4. Cavities: single or as per your requirements cavity

5. Treatment: S45C Pretreat>25Hrc,And Nitriding

6. Mould Steel: Cavity ,Core and slide: P20 ,2738,2136 available Moldbase :LKM available

7. Standard:DEM ,HUSKY,available

8. Hot runner: according to your demand

9. Life time: >300 Thousand Times

10. Package: Plywood case, anti-rust paint

1.Samples/Drawing &Requirement from you

2.Mold design:we will Communicate and Exchange the opinion with you after you place order.

3.Material Purchase:Steel cutting and mould base tooling.

4.Assembling.

5.Inspection of mould : following and controlling the tooling processing.

6.Mold testing:We will inform you the date.Than will send the sample's inspection report&injection parameters with the sample to you!

7.Your instruction &confirmation for shipment.

8.Ready made mould before packing.

9.We provide any differeny kinds of plastic injection mould, blow mould, silicone mould, die casting mould service.

Plastic molding Specification :

1. Professional manufacturer,design,production injection mould and stamping mould quality control

2. rich export experience plastic injection mould and stamping mould

3. Reasonable price of design mould

4. Cavities: single or as per your requirements cavity

5. Treatment: S45C Pretreat>25Hrc,And Nitriding

6. Mould Steel: Cavity ,Core and slide: P20 ,2738,2136 available Moldbase :LKM available

7. Standard:DEM ,HUSKY,available

8. Hot runner: according to your demand

9. Life time: >300 Thousand Times

10. Package: Plywood case, anti-rust paint

Product packaging

Exhibition

FAQ

Q:How can you confirm the plastic injection mold you produce is the one we need?

A: we can provide professional mold analysis reports before mold making .

Q:What can we do if we don’t have the mold drawing ?

A: you will only provide the actual sample to us then we can help you to make the design injection mold drawings for your confirmation

Q:Can we test the plastic injection mold?

A:after the mold is ok ,we can help you to test the mold for free.

Q:Can you process the die-casting parts of injection mold?

A: We can help to process die-casting parts for small run or mass production.

Q:What about the plastic products samples are wrong?

A: if you are not satisfied with the plastic sample, we can send the sample to you again for free.

A: we can provide professional mold analysis reports before mold making .

Q:What can we do if we don’t have the mold drawing ?

A: you will only provide the actual sample to us then we can help you to make the design injection mold drawings for your confirmation

Q:Can we test the plastic injection mold?

A:after the mold is ok ,we can help you to test the mold for free.

Q:Can you process the die-casting parts of injection mold?

A: We can help to process die-casting parts for small run or mass production.

Q:What about the plastic products samples are wrong?

A: if you are not satisfied with the plastic sample, we can send the sample to you again for free.

Hot Searches