- Product Details

- {{item.text}}

Quick Details

-

EINECS No.:

-

231-072-3

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

jinhua

-

Model Number:

-

113AB-1

-

Type:

-

Liquid Glue

-

Color:

-

Clear

-

Product name:

-

epoxy resin

-

Keywords:

-

two part epoxy resin

-

Shelf life:

-

6 Months

-

Certificate:

-

ROHS,REACH, PAHS, ASTM, EN-71

-

Mixing Ratio:

-

A:B=3:1

-

Material:

-

Epoxy

-

Hardness, shore D:

-

<85

-

Withstand voltage, KV/mm:

-

22

-

Compressive strength, Kg/ mm2:

-

8.4

Quick Details

-

CAS No.:

-

38891-59-7

-

Other Names:

-

epoxy floor

-

MF:

-

C15H16O2C2H7ONC3H5OCl

-

EINECS No.:

-

231-072-3

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

jinhua

-

Model Number:

-

113AB-1

-

Type:

-

Liquid Glue

-

Color:

-

Clear

-

Product name:

-

epoxy resin

-

Keywords:

-

two part epoxy resin

-

Shelf life:

-

6 Months

-

Certificate:

-

ROHS,REACH, PAHS, ASTM, EN-71

-

Mixing Ratio:

-

A:B=3:1

-

Material:

-

Epoxy

-

Hardness, shore D:

-

<85

-

Withstand voltage, KV/mm:

-

22

-

Compressive strength, Kg/ mm2:

-

8.4

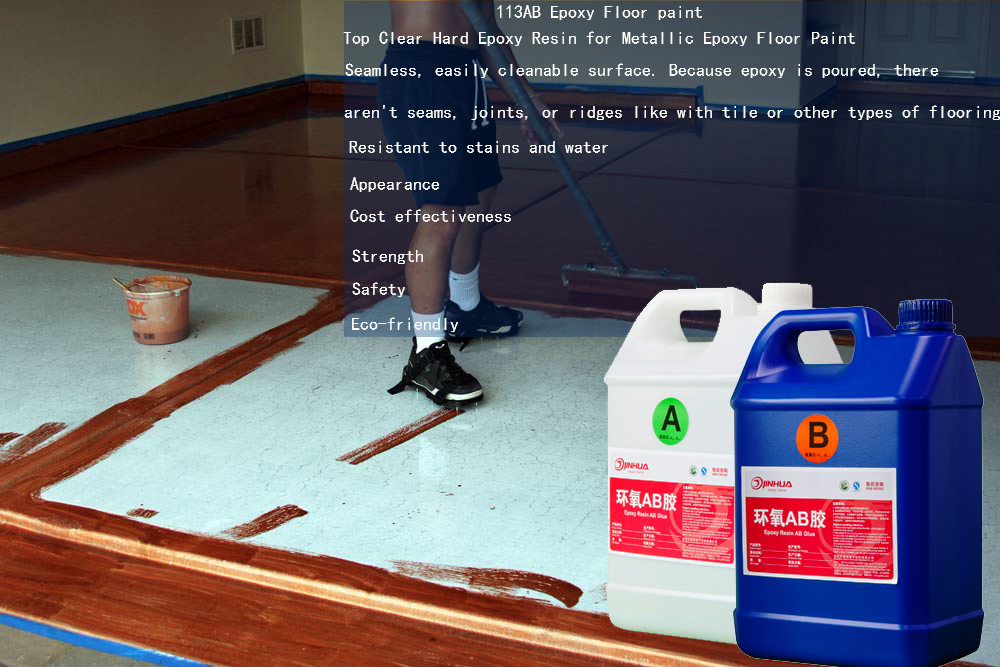

Application

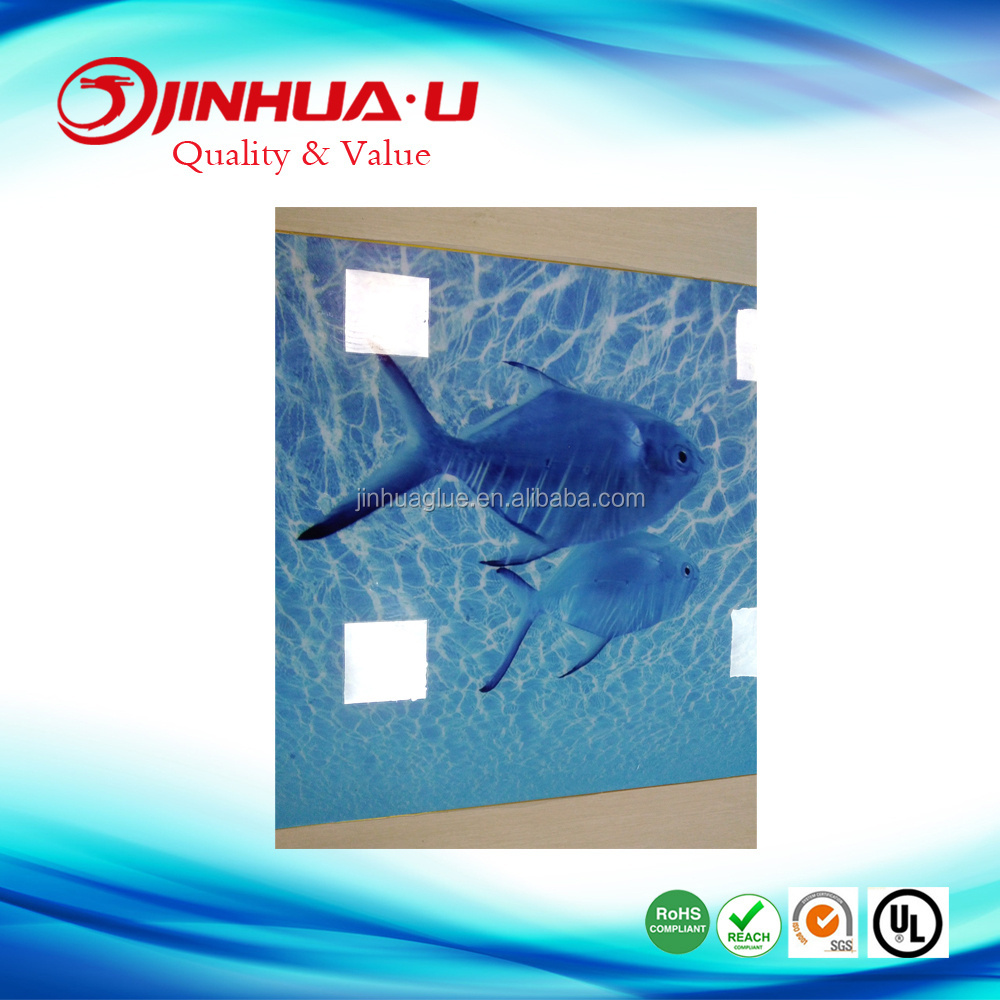

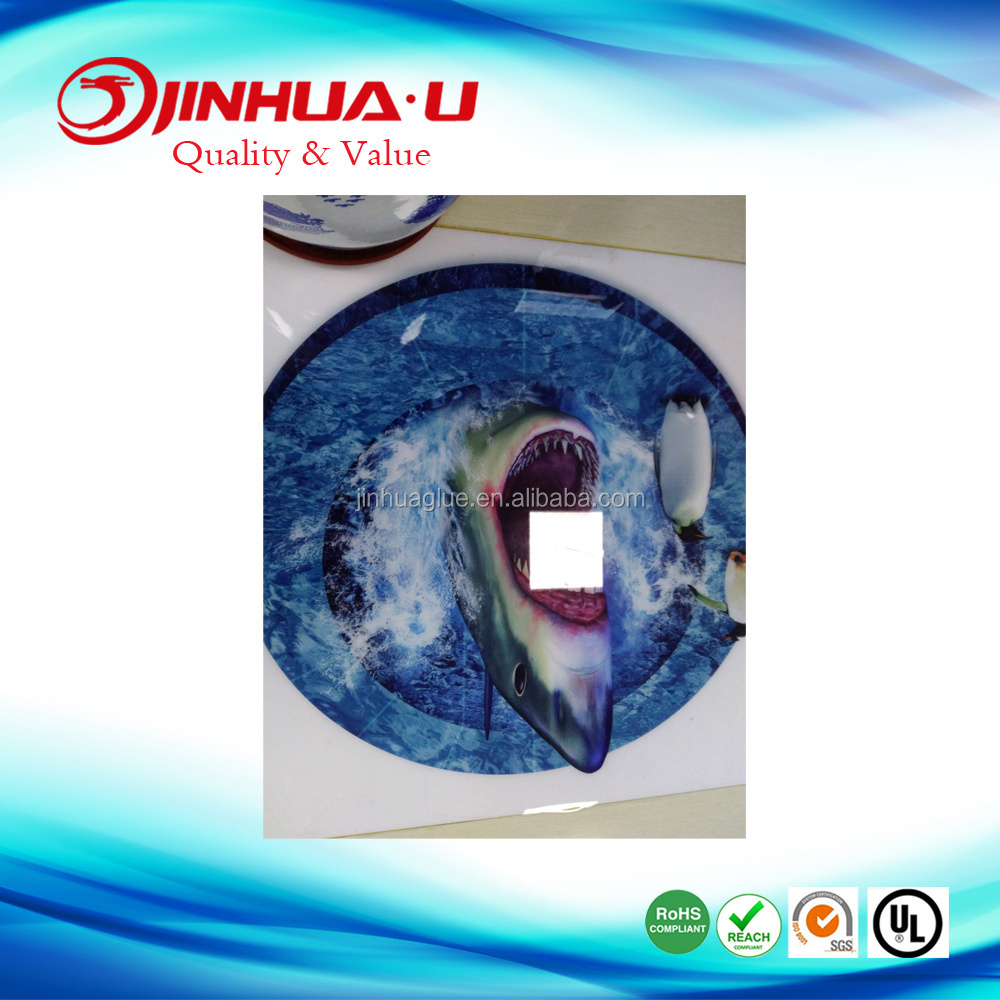

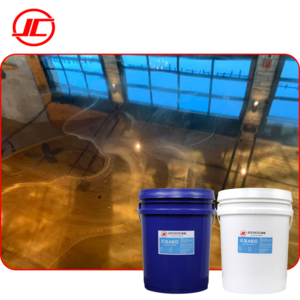

113AB-1 can be widely used for photo frame coating, crystal flooring coating, hand made jewelry, and mold filling, etc ..

Feature

Epoxy resin 113 AB -1 c an be cured under normal temperature, with the feature of low viscosity and good flowing property, natural defoaming, anti-yellow, high transp a r e ncy, no ripple, bright in surface .

P roperties before H ar dening

|

Part |

113A-1 |

113B-1 |

|

Color |

T ransparent |

T ransparent |

|

Specific gravity |

1. 1 5 |

0.9 6 |

|

Viscosity ( 25 ℃ ) |

2000 - 4000 CPS |

80 MAXCPS |

|

Mixing ratio |

A: B = 100 : 33 (weight ratio) |

|

|

Hardening conditions |

25 ℃× 8 H to 1 0 H or 55℃× 1 .5H (2 g) |

|

|

Usable time |

25℃× 4 0min (100g) |

|

Operation

1. Weigh A and B glue according to the given weight ratio into the prepared cleaned container , fully mixed the mixture again the container wall by clockwise , place it along for 3 to 5 minutes , and then it can be used.

2. Take the glue a ccording to the usable time and dosage of mix ture to avoid wasting. When the temperature is below 15 ℃, please heat A glue to 30 ℃ first and then mix it to the B glue ( A glue will be thicken in low temperature ); The glue m ust be sealed lid after use to avoid rejecti on caused by moisture absorption.

3.When the relative humidity is higher than 85%, the surface of the cured mixture will absorb moisture in the air, and form a layer of white mist in the surface , so when the relative humidity is higher than 85%, is not suitable for room temperature curing, suggest to use the heat curing.

P roperties after H ardening

|

Hardness , shore D |

< 85 |

|

Withstand voltage , KV/mm |

2 2 |

|

Flexural strength , Kg/mm2 |

28 |

|

Volume resistivity , Ohm3 |

1x10 15 |

|

Surface resistance , Ohmm2 |

5X10 15 |

|

Thermal conductivity , W/M.K |

1.36 |

|

Induced electric loss , 1KHZ |

0.42 |

|

Withstand high temperature , ℃ |

80 |

|

Moisture absorption , % |

<0.15 |

|

Compressive strength , Kg/ mm2 |

8 .4 |

Caution

1

,

The operating environment should be ventilat

e

and should keep away

from

fire. Closely sealed after use.

2 , Avoid eye contact , i n case of contact, wash with plenty of water and get medical attention immediately.

3, If contact skin, wrap with clean cloth or paper, and wash it with water and soap.

4 , Keep away from children.

5 , Ple a se take a trial before application to avoid usage mistake .

Certificate

IF YOU WANT FREE SAMPLE, PLS PRESS HERE.

Show Products