- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

ZK

-

Dimension(L*W*H):

-

2780*2478*2855

-

Weight:

-

16200 KG

-

Model:

-

PF-1310

-

Inlet size(mm):

-

490*1170

-

Max feed size(mm):

-

400

-

Boundary size(mm):

-

2780*2478*2855

-

Weight(t):

-

16.2

-

After sale Service:

-

for the whole using life

-

Certification:

-

ISO CE

-

Spare parts supply:

-

Anytime

-

History:

-

60 years

Quick Details

-

Application:

-

Ore

-

Capacity(t/h):

-

Max.140t/h, 80-140

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

ZK

-

Dimension(L*W*H):

-

2780*2478*2855

-

Weight:

-

16200 KG

-

Model:

-

PF-1310

-

Inlet size(mm):

-

490*1170

-

Max feed size(mm):

-

400

-

Boundary size(mm):

-

2780*2478*2855

-

Weight(t):

-

16.2

-

After sale Service:

-

for the whole using life

-

Certification:

-

ISO CE

-

Spare parts supply:

-

Anytime

-

History:

-

60 years

Factory Large Capacity Pf 1315 Impact Model Crusher For Rock Stone Ore Fine Crushing

Introduction

PF Series Impact Crusher is one kind of equipment to crushing the brittle material which compression strength no more than 320 Mpa, the advantage including high crushing ratio, uniform product grain and low over crushing, low energy consumption, high adjustment range of product grain size and optional crushing etc, which is mainly used in mine, metallurgy, cement, construction material, coal etc for secondary crushing and fine crushing the medium hardness material.

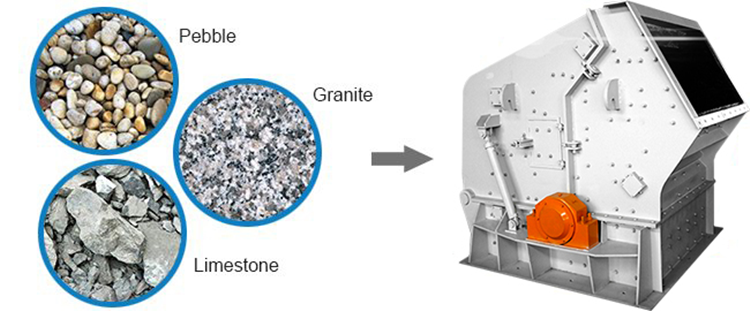

Application of Impact Crusher

Metallurgy, construction material, mine, beneficiation and large block material crushing.

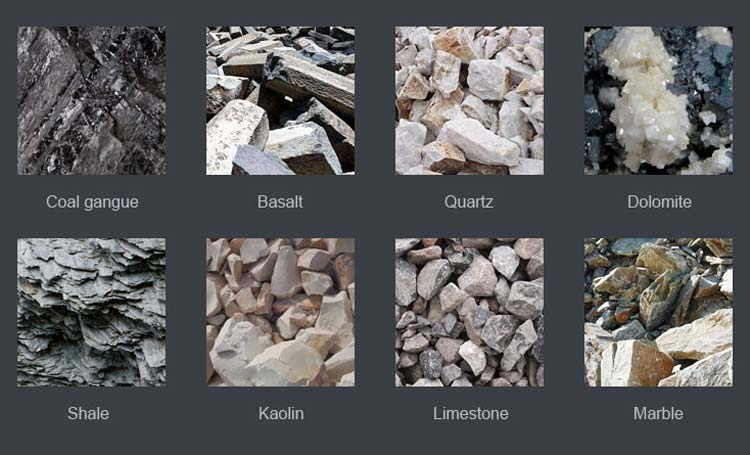

Applicable Materials

Dealing with the material with the side length 500mm, not more than 320Mpa anti-pressure strength.

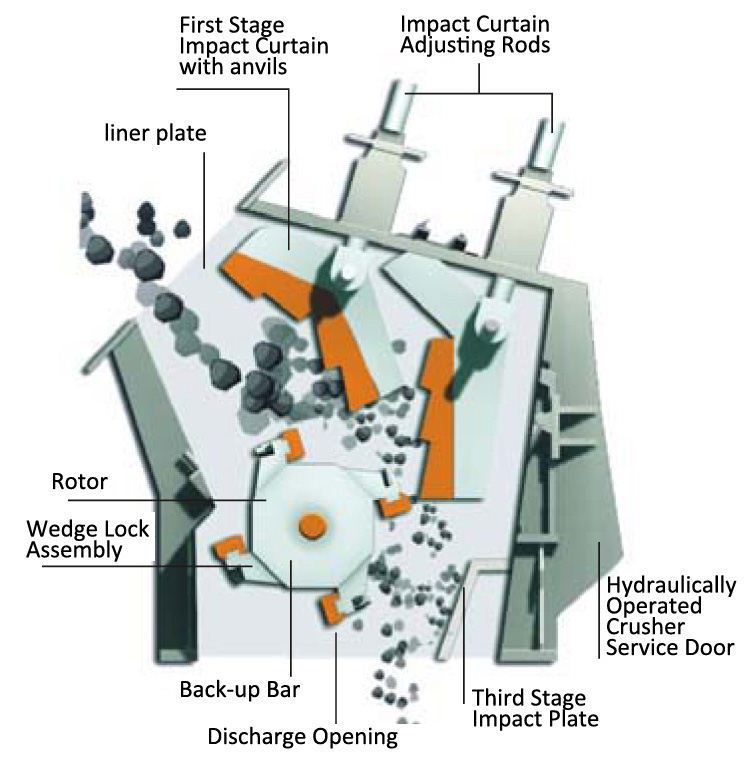

ZK PF series stone impact crusher's working principle

It featuring a 4 rows blow bar balanced rotor assembly, these machines offer smooth operation. When the impact crusher working, the motor drives the rotor rotate at a high speed, on the rotor where the blow bar installed. When the materials goes into the area which the blow bar effects, under the impact function of the blow bar at a high speed, the materials are thrown to the impact device above the rotor continuously. And then the materials are rebounded from the impact liner to the area where the blow bar effects for being crushed again. The materials from large to small all to be crushed in the impact chamber repeatedly. The process won't stop until the materials are crushed to the required size and then discharged from outlet .

Features

1. Large feeding port and high crushing cavity, suitable to crushing the material with high hardness and big grain size, and less powder.

2. The gap between impact plate and hammer plate is adjustable, so the discharging grain size can be effective controlled and the grain shape is well.

3. The hammer, impact plate and lining plate are made of new type abrasion-proof material with long working life and impact protection, wear protection.

4. Because of the function of three-stage crushing and plastic, the crushing ratio is high, and the product shape is cube and can optional crushing.

5. The multi-function hydraulic station has many function of hydraulic discharge gap with high speed, impact plate stable vibration and the body open automatically..

Technical Parameter

| Model | Specification(mm) | Inlet size(mm) | Max feed size(mm) | Capacity(t/h) | Power(kW) | Boundary size(mm) | Weight(t) |

| PF-0807 | ø850*700 | 400*730 | 300 | 15-30 | 30-45 | 2210*1490*2670 | 8.1 |

| PF-1007 | ø1000*700 | 400*730 | 300 | 30-50 | 37-55 | 2400*1558*2660 | 9.5 |

| PF-1010 | ø1000*1050 | 400*1080 | 350 | 50-80 | 55-75 | 2400*2250*2620 | 12.2 |

| PF-1210 | ø1250*1050 | 400*1080 | 350 | 70-120 | 110-132 | 2690*2338*2890 | 14.9 |

| PF-1214 | ø1250*1400 | 400*1430 | 350 | 130-180 | 132-160 | 2690*2688*2890 | 18.6 |

| PF-1310 | ø1300*1050 | 490*1170 | 400 | 80-140 | 110-160 | 2780*2478*2855 | 16.2 |

| PF-1315 | ø1320*1500 | 860*1520 | 500 | 160-250 | 180-260 | 3096*3273*2667 | 19.3 |

| PF-1415 | ø1450*1500 | 1145*1520 | 950 | 220-450 | 220-315 | 3745*3022*3519 | 27 |

| PF-1520 | ø1520*2000 | 830*2050 | 700 | 300-550 | 315-440 | 3581*3560*3865 | 36.5 |

Kenya 250 t/h Limestone Crushing Plant

Turkey Copper Ore Crushing Plant

Pre-sale services: enthusiasm

We provide you with the prophase plan, process flow design and manufacturer equipment according to your special demand.

Sale services: servant

Send technicians to the jobsite for guiding the installation and adjustment, training operators and finishing the check and accept together with you.

After-sale services: faithfulness

To establish long term friendship, we will regularly pay return visit to customers.

In addition, we provide one-year warrantee to make sure your machine runs consistently. We always keep certain inventory level of spare parts, which means the replacements can be shipped to you right away.