Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

300-9500KG depends on different machine

-

Size:

-

different as each model

-

Power:

-

different as each model, 1.5-10kw/h

-

Productivity:

-

1000g-100000g/h

-

Weight (KG):

-

100 kg

-

Product name:

-

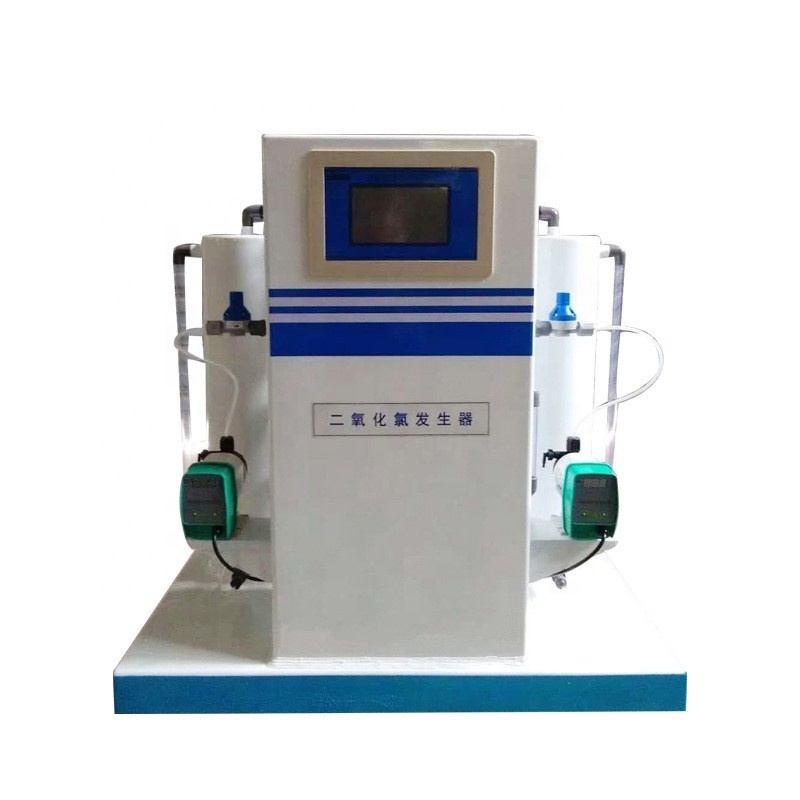

Chlorine dioxide generator

-

Application:

-

Disinfection of living, drinking and tap water

-

Function:

-

Producing Fresh Water

-

Type:

-

Pure Water Treatment System

-

Keywords:

-

chlorine dioxide generator water sterilizer

-

Usage:

-

Water Treament

-

Processing:

-

Pre-treatment+RO Desaliantion

-

Effective chlorine production:

-

1000-20000g/h

Quick Details

-

Place of Origin:

-

Guangxi, China

-

Brand Name:

-

New YuDa, New YuDa

-

Material:

-

Anticorrosive high quality pvc sheet

-

Weight:

-

300-9500KG depends on different machine

-

Size:

-

different as each model

-

Power:

-

different as each model, 1.5-10kw/h

-

Productivity:

-

1000g-100000g/h

-

Weight (KG):

-

100 kg

-

Product name:

-

Chlorine dioxide generator

-

Application:

-

Disinfection of living, drinking and tap water

-

Function:

-

Producing Fresh Water

-

Type:

-

Pure Water Treatment System

-

Keywords:

-

chlorine dioxide generator water sterilizer

-

Usage:

-

Water Treament

-

Processing:

-

Pre-treatment+RO Desaliantion

-

Effective chlorine production:

-

1000-20000g/h

Generator for water disinfection treatment ,Automatic Chlorine dioxide generator for water treatment/aquaculture industry

New YuDa Chlorine dioxide generator details specification:

| Model | Available chlorine production | Power(KW/H) | Power water pipe diameter(mm) | Pressure(Mpa) | Size L*W*H(mm) |

| NYD-P1000 | 1000 | 1.5 | 32 | 0.25 | 650*450*1400 |

| NYD-P2000 | 2000 | 2.0 | 40 | 0.25 | 650*500*1500 |

| NYD-P3000 | 3000 | 2.0 | 40 | 0.3 | 650*500*1500 |

| NYD-P4000 | 4000 | 3.0 | 50 | 0.3 | 750*550*1600 |

| NYD-P5000 | 5000 | 3.0 | 50 | 0.3 | 750*550*1600 |

| NYD-P8000 | 8000 | 5.0 | 63 | 0.3 | 750*600*1800 |

| NYD-P10000 | 10000 | 5.0 | 63 | 0.3 | 750*600*1800 |

| NYD-P15000 | 15000 | 7.5 | 75 | 0.4 | 850*650*1900 |

| NYD-P20000 | 20000 | 10.0 | 75 | 0.4 | 850*650*1900 |

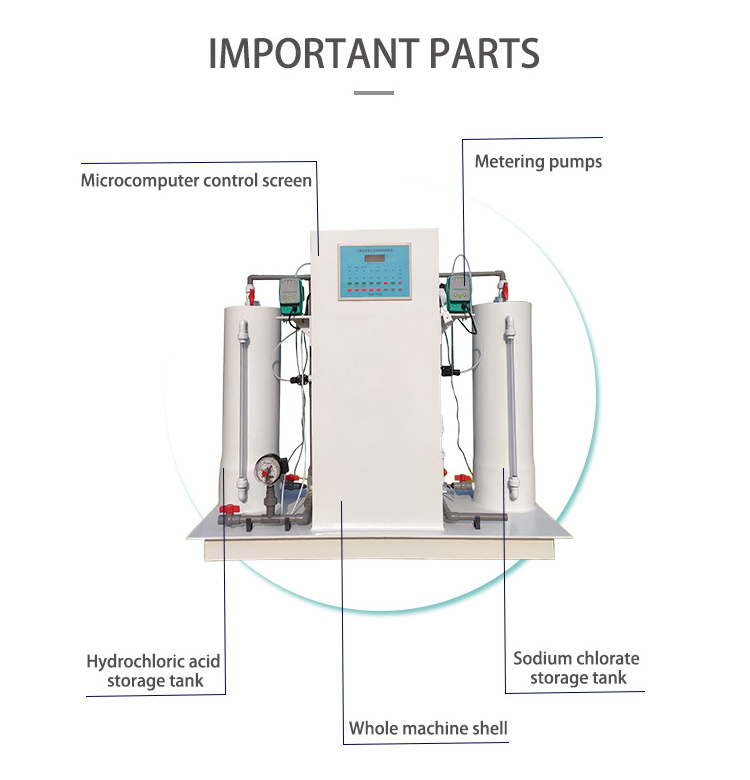

Product composition

Feeding system, reaction system, control system, absorption system, safety system heating system

Process principle

NaCLO3+2HCL=CLO2+1/2CL2+H2O+NaCL

Industrial raw materials

Sodium chlorate (industrial grade 99% content), hydrochloric acid (industrial synthetic grade 1, concentration 31%)

Performance characteristics

The reaction system adopts pure titanium material, which is resistant to high temperature, corrosion and long life.

Reaction heating temperature 55-78X), raw material conversion rate 85%O

The feeding system is equipped with international famous brand metering pump, constant back pressure device, and accurate metering.

The control system adopts PLC, an intelligent industrial man-machine interface. It has automatic shutdown protection for faults such as power water underpressure, underflow and material shortage (optional), parameter display and record and central control functions.

The heating system adopts the electric heating method, which has fast conduction, time saving and power saving. When the PLC control system is overhauled, the equipment can still run in the manual state.

The external signal follow-up and linkage unit can receive the 4-20Ma standard signal representing flow and residual chlorine, and according to the input signal, change the feeding speed of raw materials to realize open-loop proportional and closed-loop automatic control feeding.

The communication unit has a MODBUS 485 communication interface, a hard-wired communication interface, and uses the PROFIBUS communication protocol to communicate with the upper computer to realize remote monitoring.

Raw material consumption

Each production of 1g of available chlorine consumes 0.55g of sodium chlorate and 1.1g of hydrochloric acid. This equipment is suitable for dosing in reservoirs. Industrial Automation Control

New YuDa Chlorine dioxide generator advantages:

1. The use of pure titanium reaction pot, corrosion resistance and high temperature, compression.

The product has a longer service life, the reaction speed and conversion rate are significantly improved, and raw materials are saved.

2. Using imported stability accessories from the United States, Germany, Italy and Switzerland, etc., the operation is stable and the accuracy is high.

3. The inside of the host is connected by chemical pipe fittings of Huanqi and other brands, which is compressive and heat-resistant.

Fourth, the equipment shell is made of anti-corrosion high-quality pvc sheet, which is firmly welded and does not deform.

5. The appearance of the equipment adopts the automobile baking paint process, which is bright and smooth, neat and generous.

6. The PVC raw material tank adopts the pressure-resistant pipe fittings of the Formosa Plastics brand, and the internal double leak-proof design ensures the safety of raw material storage.

7. The electrical components of the equipment use brands such as Schneider and Chint to ensure safety.

Eight, to provide high-standard installation and commissioning services. The pipeline layout is reasonable, safe and beautiful.

Nine, equipment versatility, the same equipment, can use various combinations of raw materials,

(hydrochloric acid + sodium chlorate), (hydrochloric acid + sodium chlorite), (stable chlorine dioxide dry powder)

(Stable chlorine dioxide AB agent)

New YuDa Chlorine dioxide generator usage scenrio:

1. Disinfection of living, drinking and tap water in various occasions;

2. Sterilization and disinfection of sanitary facilities in restaurants, hotels, homes, tableware and air environment, etc.

3. Final sterilization and disinfection of equipment, pipelines and containers in food, beverage factories and fermentation industries.

4. Sterilization of pipelines, facilities and environments of dairy plants and slaughterhouses;

5. Sterilization and disinfection of hospital sewage;

6. Sterilization and disinfection of swimming pool, industrial circulating water and bath water;

7. Anti-mildew treatment for disinfection, sterilization and deodorization of hospital, sanitary and clinical equipment;

8. Preservation and final rinsing and disinfection of food such as households, hotels, restaurants, fruits and vegetables, and fish;

9. Configure various oral disinfectants, deodorants and wound cleaning solutions.

10. Sterilization and deodorization in wastewater reuse;

11. Bleaching agent for flour and various foods;

12. Bleaching agents in papermaking, printing and dyeing industries;

13. Cyanide breaking treatment of electroplating wastewater containing cyanide, decolorization treatment of printing and dyeing wastewater, algae removal and sterilization treatment of industrial cooling water.