- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Joyang

-

Voltage:

-

380V 50HZ (Customized)

-

Power:

-

53kw - 195kw

-

Weight:

-

56900 KG

-

Dimension(L*W*H):

-

17*2*2.5 - 42*2.8*4m

-

Product name:

-

Pet Food Making Machine

-

Raw Material:

-

Corn Powder Rice powder fish meal animal oil etc

-

Function:

-

Producing Animal Feeds

-

Energy:

-

Electricity

-

Advantage:

-

Good puffing effect

-

Feature:

-

High Efficiency

-

Capacity:

-

140 - 1000 kg/h

-

Operation:

-

1 - 2 Workers

-

Processing Types:

-

Twin-Screw Extrusion

-

Automatic:

-

High Automatic

Quick Details

-

Applicable Industries:

-

Pet food and Fish feed factory

-

Marketing Type:

-

New Product 2021

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Joyang

-

Voltage:

-

380V 50HZ (Customized)

-

Power:

-

53kw - 195kw

-

Weight:

-

56900 KG

-

Dimension(L*W*H):

-

17*2*2.5 - 42*2.8*4m

-

Product name:

-

Pet Food Making Machine

-

Raw Material:

-

Corn Powder Rice powder fish meal animal oil etc

-

Function:

-

Producing Animal Feeds

-

Energy:

-

Electricity

-

Advantage:

-

Good puffing effect

-

Feature:

-

High Efficiency

-

Capacity:

-

140 - 1000 kg/h

-

Operation:

-

1 - 2 Workers

-

Processing Types:

-

Twin-Screw Extrusion

-

Automatic:

-

High Automatic

Wet Extrusion Pet Food Machine Adult Dog Food Production Line Dry Extrusion Dog Food Equipment

Product Description

Pet food making machines use meat powder, fish meal, bone meal, cornflour, cereals, and beans are used as raw materials to produce pet food and fish feed with unique tastes and new shapes, such as heart, bones, stars, triangles, circles, etc. Meet all kinds of pets, such as dogs, cats, turtles., fish, shrimp, etc. let the pet eat happier and live healthier. And this line can also make the cored filling pet food, it will be more popular with model pets.

Product Parameters

| Model | Installed Power | Power Consumption | Production Capacity | Dimension |

| JY-65 | 76kw | 53kw | 140-160kg/h | 17*2*2.5m |

| JY-70 | 105kw | 75kw | 240-260kg/h | 22*2*2.5m |

| JY-85 | 178kw | 125kw | 500kg/h | 26*2*3.5m |

| JY-95 | 256kw | 195kw | 1000-1500kg/h | 42*2.8*4m |

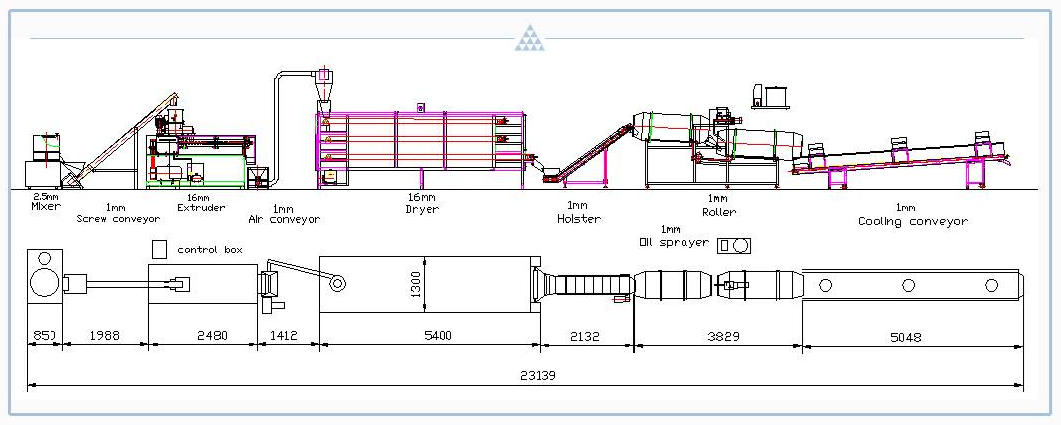

Flowchart Diagram

Machine List

Machine List

Mixer ⇒ Screw Conveyor ⇒ Extruder ⇒ Air Conveyor ⇒ Dryer ⇒ Hoister ⇒ Oil Sprayer ⇒ Twin Rollers ⇒ With Flavoring Machine ⇒ Cooling Conveyor

|

Mixer

|

This machine can mix all the different kinds of powder materials with water. Due to the high speed of mixing braches 580Rpm, the different materials can be mixed evenly with water and some other liquid material. |

| This machine is used to elevate powder material into the next machine in a closed tube. It is clean and high efficiency. |

Screw Conveyor

|

|

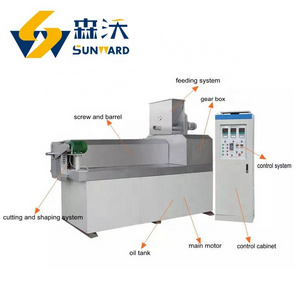

Extruder

|

This machine is used to puff or cook the material via high temp and high pressure. With an automatic temp controlling system and automatic speed control system, you will get different food based on different crafts. The shape of the food can also be controlled by different molds. |

| This machine can convey the food to the next machine via a closed stainless steel pipe by air. It is clean and high efficiency. There is a cyclone that can release the air and leave the food to the next machine. |

Air Conveyor

|

| Dryer | The multi-dryer is with a compact design that can make the food be well dried in a limited space. We can adjust the number of layers and lengths depending on the output of the oven. It is a food standard stainless steel belt. The temp of the dryer and the drying time can both be controlled which can make sure that the food will be fully dried. We can also provide a gas dryer, diesel dryer, steam dryer, or even a double energy dryer. |

| The hosier is used to elevate the food into the next machine with both horizontal vertical edges which can make sure is no leaking. |

Hoister With Flavor

|

|

Oil Sprayer

|

This machine is used to spray oil and another liquid flavor on the snacks food or feed. There is a heating pipe inside the drum which can make the oil be liquid even in wintertime. |

| This machine is used to flavor the food continuously. It is fully automatic. It is stainless steel. |

Twin Rollers With Flavoring Machine

|

|

Cooling Conveyor

|

There are totally two functions for this machine. Cooling and conveying. Generally, there are fans over the stainless belt. It can also take the food from one workshop to another. |

Customer And Service

We exported the machines to many countries all around the world, such as Italy, Germany, Russia, Turkey, Australia, Indonesia, India, etc. Almost all the customers speak highly of our machines and service, and they continue to buy from us again and again.

1. One-year complete warranty.

2. Free consultation service before during and after-sales.

3.Provide basic production techiques and formules.

4. Overseas installation and traning of equipment maintenance and operating personally.

5. Debugging and inspecting of equipment until everything is functional before leaving the factory.