- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

JIJ

-

Model Number:

-

45 Milling Cutter

-

Product Name:

-

Milling Cutter

-

Application:

-

CNC

-

Suitable for:

-

Metal Plane Processing

-

Size:

-

1-20 mm

-

OEM:

-

Support Non-standard Customization

-

Workpiece Material:

-

Carbon Steel /Die Steel

-

Usage:

-

For Slotting, Groove Milling

-

HRC:

-

45/55/60/65

Quick Details

-

Material:

-

Carbide, Tungsten Cobalt Alloy

-

Coating:

-

TiAIN

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

JIJ

-

Model Number:

-

45 Milling Cutter

-

Product Name:

-

Milling Cutter

-

Application:

-

CNC

-

Suitable for:

-

Metal Plane Processing

-

Size:

-

1-20 mm

-

OEM:

-

Support Non-standard Customization

-

Workpiece Material:

-

Carbon Steel /Die Steel

-

Usage:

-

For Slotting, Groove Milling

-

HRC:

-

45/55/60/65

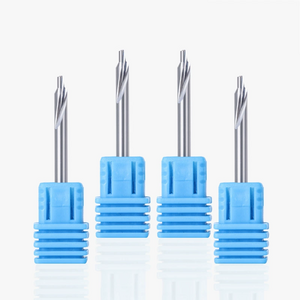

Products Description

Details Images

The use of micro-grained tungsten steel base material, with higher wear resistance and strength belongs to the high hardness and high-speed cutting applications of the exclusive milling cutter

Universal chamfered round handle, easy to use, with good compatibility, enhance the seismic and cutting speed of the milling cutter, clamping tighter without slipping

Spiral angle makes the milling cutter more wear-resistant, reduces product burrs during processing, and removes chips more smoothly

Large core diameter design is adopted under the condition of capacity cutting space, which greatly enhances the rigidity and shock resistance of the tool and reduces the breaking of the tool

Product Paramenters

|

|

d

|

H

|

D

|

L

|

Fluted/z

|

|

d1*3*D4-50L

|

1

|

3

|

4

|

50

|

2/3/4

|

|

d1.5*4.5*D4-50L

|

1.5

|

4.5

|

4

|

50

|

2/3/4

|

|

d2*6*D4-50L

|

2

|

6

|

4

|

50

|

2/3/4

|

|

d2.5*7.5*D4-50L

|

2.5

|

7.5

|

4

|

50

|

2/3/4

|

|

d3*9*D4-50L

|

3

|

9

|

4

|

50

|

2/3/4

|

|

d3*9*D3-50I

|

3

|

9

|

3

|

50

|

2/3/4

|

|

d3*12*D3-75L

|

3

|

12

|

3

|

75

|

2/3/4

|

|

d3*15*D3-100L

|

3

|

15

|

3

|

100

|

2/3/4

|

|

d3.5*10*D4-50L

|

3.5

|

10

|

4

|

50

|

2/3/4

|

|

d4*10*D4-50L

|

4

|

10

|

4

|

50

|

2/3/4

|

|

d4*16*D4-75I

|

4

|

16

|

4

|

75

|

2/3/4

|

|

d4*20*D4-100L

|

4

|

20

|

4

|

100

|

2/3/4

|

|

d5*13*D6-50L

|

5

|

13

|

6

|

50

|

2/3/4

|

|

d5*13*D5-50L

|

5

|

13

|

5

|

50

|

2/3/4

|

|

d5*20*D5-75L

|

5

|

20

|

5

|

75

|

2/3/4

|

|

d5*25*D5-100L

|

5

|

25

|

5

|

100

|

2/3/4

|

|

d6*15*D6-50L

|

6

|

15

|

6

|

50

|

2/3/4

|

|

d6*24*D6-75L

|

6

|

24

|

6

|

75

|

2/3/4

|

|

d6*30*D6-100L

|

6

|

30

|

6

|

100

|

2/3/4

|

|

d8*20*D8-60L

|

8

|

20

|

8

|

60

|

2/3/4

|

|

d8*30*D8-75L

|

8

|

30

|

8

|

75

|

2/3/4

|

|

d8*35*D8-100L

|

8

|

35

|

8

|

100

|

2/3/4

|

|

d10*25*D10-75L

|

10

|

25

|

10

|

75

|

2/3/4

|

|

d10*40*D10-100L

|

10

|

40

|

10

|

100

|

2/3/4

|

|

d12*30*D12-75L

|

12

|

30

|

12

|

75

|

2/3/4

|

|

d12*45*D12-100L

|

12

|

45

|

12

|

100

|

2/3/4

|

|

d14*45*D14-100L

|

14

|

45

|

14

|

100

|

2/3/4

|

|

d16*45*D16-100L

|

16

|

45

|

16

|

100

|

2/3/4

|

|

d18*45*D18-100L

|

18

|

45

|

18

|

100

|

2/3/4

|

|

d20*45*D20-100L

|

20

|

45

|

20

|

100

|

2/3/4

|

|

d6*45*D6-150L

|

6

|

45

|

6

|

150

|

2/3/4

|

|

d8*50*D8-150L

|

8

|

50

|

8

|

150

|

2/3/4

|

|

d10*60*D10-150L

|

10

|

60

|

10

|

150

|

2/3/4

|

|

d12*60*D12-150L

|

12

|

60

|

12

|

150

|

2/3/4

|

|

d14*70*D14-150L

|

14

|

70

|

14

|

150

|

2/3/4

|

|

d16*75*D16-150L

|

16

|

75

|

16

|

150

|

2/3/4

|

|

d18*75*D18-150L

|

18

|

75

|

18

|

150

|

2/3/4

|

|

d20*75*D20-150L

|

20

|

75

|

20

|

150

|

2/3/4

|

Hot Searches