- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

HLT

-

Dimensions(L*W*H):

-

6M*3M*1.5M

-

Weight:

-

500 KG

-

Certification:

-

ce

-

Max. Print Area:

-

585*883

-

Product name:

-

Silk Screen Printing Machine

-

Color:

-

2 Colors

-

Printing speed:

-

8m/min

-

Material:

-

Steel

-

After Warranty Service:

-

Video Technical Support

-

Application:

-

Materials

-

Keywords:

-

Silk Screen Printer Machine

-

Advantage:

-

Easy Handling

-

Max Printing size:

-

1600x600mm

-

Power:

-

4.5KW

Quick Details

-

Condition:

-

New

-

Color & Page:

-

Multicolor

-

Voltage:

-

24V DC

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

HLT

-

Dimensions(L*W*H):

-

6M*3M*1.5M

-

Weight:

-

500 KG

-

Certification:

-

ce

-

Max. Print Area:

-

585*883

-

Product name:

-

Silk Screen Printing Machine

-

Color:

-

2 Colors

-

Printing speed:

-

8m/min

-

Material:

-

Steel

-

After Warranty Service:

-

Video Technical Support

-

Application:

-

Materials

-

Keywords:

-

Silk Screen Printer Machine

-

Advantage:

-

Easy Handling

-

Max Printing size:

-

1600x600mm

-

Power:

-

4.5KW

Overview

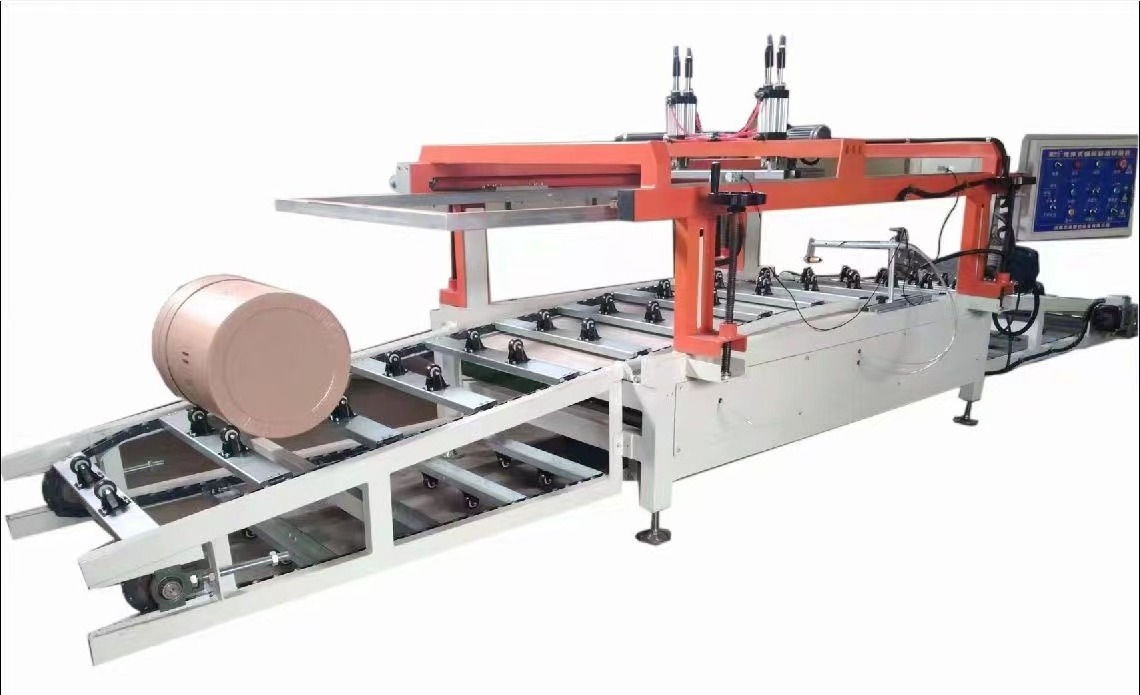

Automatic multiple colour Silk Screen Printing Machine for Conical Cylindrical Steel Drum Barrel

Product Description

Specification

|

Structure

|

All steel structure, painted

|

|

Positioning system

|

Adopts photoelectric positioning

|

|

Motor

|

Adopts the corresponding product of Chinese High-quality brand(Shanghai Guoyou)

|

|

Industrial control system

|

Siemens PLC program controller and electronic control accessories choose national high-quality product brands

|

|

Production capacity

|

8 drums/min

|

|

Conveying method

|

Stepping

|

Machine Details

Finished steel drum after silk printing

Related Machines

Drum Painting Spray Booth

The painting room is mainly composed of the main body of the painting room, the rotating and stepping conveying mechanism for the painting, the paint supply system and the electrical control system.

Steel drum drying oven

The paint drying room has the function of drying the coating on the surface of the steel barrel. The drying temperature in the drying tunnel must be uniform and equipped with a hot air circulation system and a diversion system. It consists of the followingparts: front conveying device, front transmission device, drying tunnel body, main conveying chain, hot air duct, heating system,rear exhaust device, cooling device, rear transmission device, rear conveying device electrical control system, pneumatic system,exhaust duct part.

- Length of drying tunnel: 20 meters

- Cooling length: 4 meters

- Inside width of drying tunnel: 1100mm

- Height inside drying tunnel: 1800mm

- Conveying form: single-row bucket, vertical, using C2080 double-pitch standard conveying chain. - Steel barrel specifications:

φ570 * 930mm

- Production capacity: 100 pcs / hour (adjustable running speed),

- Working temperature: 120°C -180°C adjustable

- Drying time: 15 minutes (according to the drying temperature of the coating process)

- Fuel type: natural gas.

- Installed capacity: 250000kcal / h (according to coating process drying temperature)

- Number of heating chambers: 1 set

- Conveyor line elevation: 820m

- Cooling length: 4 meters

- Inside width of drying tunnel: 1100mm

- Height inside drying tunnel: 1800mm

- Conveying form: single-row bucket, vertical, using C2080 double-pitch standard conveying chain. - Steel barrel specifications:

φ570 * 930mm

- Production capacity: 100 pcs / hour (adjustable running speed),

- Working temperature: 120°C -180°C adjustable

- Drying time: 15 minutes (according to the drying temperature of the coating process)

- Fuel type: natural gas.

- Installed capacity: 250000kcal / h (according to coating process drying temperature)

- Number of heating chambers: 1 set

- Conveyor line elevation: 820m

Hot Searches