- Product Details

- {{item.text}}

Quick Details

-

Thickness:

-

0.2 - 0.5 mm

-

Place of Origin:

-

Shanghai, China

-

Model Number:

-

50W470

-

Product Name:

-

oriented electrical silicon steel coils

-

Application:

-

Motor

-

Material:

-

CRNO 50W470/600/800

-

Steel shape:

-

Steel Coil Crgos

-

Certificate:

-

ISO9001

-

Width:

-

10mm-1200mm

-

Process:

-

Winding Annealing

-

Color:

-

Gray

-

Product Keywords:

-

silicon steel coil

-

MOQ:

-

10 Tons

Quick Details

-

Type:

-

Non-oriented Silicon Steel

-

Tolerance:

-

±1%

-

Grade:

-

50W470

-

Thickness:

-

0.2 - 0.5 mm

-

Place of Origin:

-

Shanghai, China

-

Model Number:

-

50W470

-

Product Name:

-

oriented electrical silicon steel coils

-

Application:

-

Motor

-

Material:

-

CRNO 50W470/600/800

-

Steel shape:

-

Steel Coil Crgos

-

Certificate:

-

ISO9001

-

Width:

-

10mm-1200mm

-

Process:

-

Winding Annealing

-

Color:

-

Gray

-

Product Keywords:

-

silicon steel coil

-

MOQ:

-

10 Tons

Products Description

The difference between oriented silicon steel and non-oriented silicon steel

Non-oriented silicon steel: ferrosilicon alloy with very low carbon content. The silicon content of the alloy is 1.5% to 3.0%, or the sum of the silicon and aluminum content is 1.8% to 4.0%. The products are usually cold-rolled plates or strips, which are mainly used to manufacture motors and generators.

Oriented silicon steel: It has strong directionality, the lowest iron loss value in the rolling direction, the highest magnetic permeability, and a higher magnetic induction value under a certain magnetization field. The silicon content of oriented silicon steel is about 3%. It also requires a low content of oxide inclusions in the steel and must contain certain inhibitors (MnS, A1N).

Oriented silicon steel: It has strong directionality, the lowest iron loss value in the rolling direction, the highest magnetic permeability, and a higher magnetic induction value under a certain magnetization field. The silicon content of oriented silicon steel is about 3%. It also requires a low content of oxide inclusions in the steel and must contain certain inhibitors (MnS, A1N).

Specification

|

Name

|

Rolling

|

Orientation

|

Silicon Content

|

Use

|

|

Hot Rolled Low Silicon Steel

|

Hot Rolled

|

No Orientation

|

1.0%-2.5%

|

Household Motors And Micromotors

|

|

Hot Rolled High Silicon Steel

|

Hot Rolled

|

No Orientation

|

3.0%-4.5%

|

Transformer

|

|

Cold Rolled Grain Oriented Electrical Steel

|

Cold Rolled

|

Normal Orientation/High Magnetic Induction Orientation

|

|

Large, Medium And Small Transformers

|

|

Low Carbon Electrical Steel

|

Cold Rolled

|

No Orientation

|

<0.5%

|

Household Motors, Micromotors, Small Transformers And Ballasts

|

|

Silicon Steel

|

Cold Rolled

|

No Orientation

|

0.5%-3.5%

|

Medium And Large Motors, Generators And Transformers

|

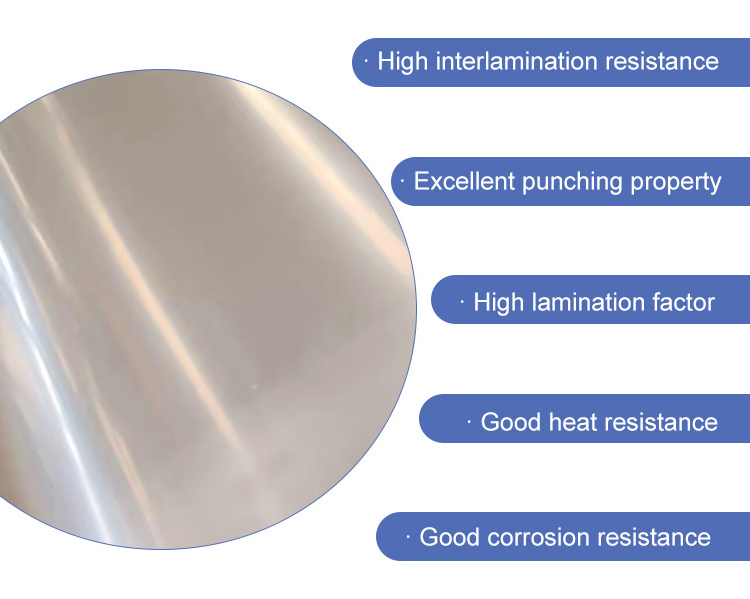

INSULATING COATING

Insulating Coating

The surface of GO silicon steel products is coated with a layer of inorganic insulating coat, which has the following excellent coating features:

High interlamination resistance —

Excellent punching property —

Close combination of coat and substrate give rise to good adhesiveness, which can prevent peeling of coat during processing.

High lamination factor —

Surface coat is uniform and thin, so that the lamination factor is good.

Good heat resistance —

The coat can withstand 800℃ annealing without damage.

Good corrosion resistance —

The coat is incompatible with cooling oil, insulating oil, mechanical oil, Freon and antifreezing oil, so it is immune from their corrosion.

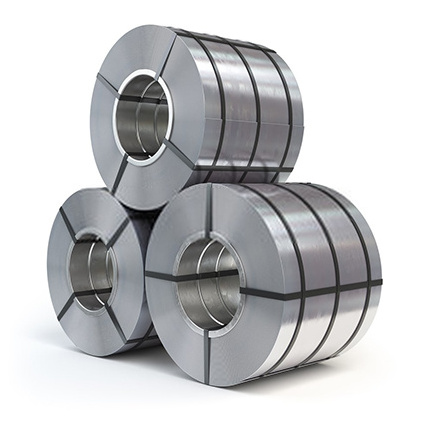

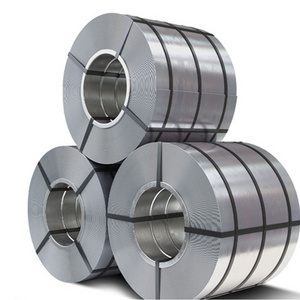

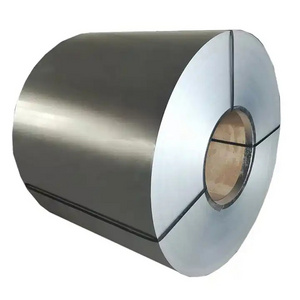

Product Type

More Style Choices

Customized according to customer

Contact Us

Product Advantages

Details Images

Packing & Delivery

Hot Searches