- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

Specially customized as clients' local power

-

Power:

-

Customized

-

Dimension(L*W*H):

-

Automatic Powder Coating Line

-

Weight (KG):

-

1000

-

advantage:

-

High-efficiency,environmental-protection

-

Control System:

-

PLC+Touch Screen Automatic

-

output:

-

Debug according to customer requirements

-

energy:

-

Natural gas, power

-

Product name:

-

JRX full automatic powder coating line

-

Product line type:

-

Hardware accessories painting production line

-

size:

-

Depending on customer needs

-

package:

-

According to customer request Package

-

Furnace temperature:

-

120-150℃

Quick Details

-

Machine Type:

-

powder painting line, Spray Booths, Painting Equipment, Plc Controller Programmable Logic Controller, Pre-treatment Equipment, Conveying Equipment, Drying Oven, Curing oven, Coating Equipment, Anodized Equipment, Sandblasting Machine

-

Place of Origin:

-

China

-

Brand Name:

-

JRX

-

Voltage:

-

Specially customized as clients' local power

-

Power:

-

Customized

-

Dimension(L*W*H):

-

Automatic Powder Coating Line

-

Weight (KG):

-

1000

-

advantage:

-

High-efficiency,environmental-protection

-

Control System:

-

PLC+Touch Screen Automatic

-

output:

-

Debug according to customer requirements

-

energy:

-

Natural gas, power

-

Product name:

-

JRX full automatic powder coating line

-

Product line type:

-

Hardware accessories painting production line

-

size:

-

Depending on customer needs

-

package:

-

According to customer request Package

-

Furnace temperature:

-

120-150℃

Product Overview

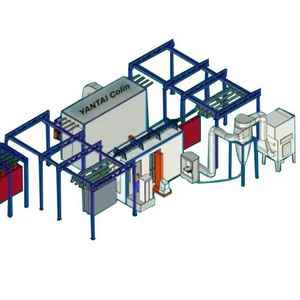

Full-Automation Powder Coating Line

The design of the automatic spraying line reduces a lot of labor. It mixes the powder with air in the powder feeder and sends it to the powder spray gun.

The high voltage generated by the high-voltage electrostatic generator is connected to the inside or front end of the powder spray gun.

The inside or outlet of the powder spray gun is charged, and under the combined action of air force and electrostatic force, the powder particles are sprayed on the workpiece to be coated in a directional direction.

Safety and environmental protection, high output, high efficiency, uniform coating.

Pretreatment equipment

Pretreatment equipment is widely used in the household appliance spraying industry (air conditioner, refrigerator, washing machine, etc.), mainly to effectively clean the oil stain generated during the processing of the product shell, form a protective film on the product surface, and improve the adhesion of the workpiece after powder spraying in the subsequent process. Ensure that the powder coating of the product is not easy to fall off and rust.

Moisture drying furnace

the main body of the drying rack is made of square tubes, and the chamber body is a plug-in plate combined bridge insulation structure, which is convenient for transportation and installation.

during installation, 100mm thick rock wool shall be pasted at the joint of furnace plate for insulation to ensure that there is no leakage at the wall joint. The average surface temperature of the outer wall of the drying channel shall not be higher than the ambient temperature by 15 ℃ (when the ambient temperature is 20 ℃).

the assembly plate of the oven chamber is divided into inner plate and outer plate, and the inner plate is selected δ= It is made of 0.5mm galvanized steel plate, and the outer side plate is selected δ= Made of 0.5mm color plate; Fill between inner and outer panels δ= 120mm rock wool insulation reduces heat transfer.

oven temperature control is to control the working state of the heater by outputting the command signal after comparing the electrical signal measured by the temperature sensor with the set temperature value (analog quantity) through the digital display temperature controller, so as to realize the automatic control / digital display of the furnace temperature.

interlock protection and automatic time delay control are adopted to ensure that the heater can only be turned on when the circulating fan works normally under any circumstances. After the heater stops working, the fan still works for a period of time to blow away the hot gas in the heating room for protection.

hot air circulation in drying furnace 3 times / minute

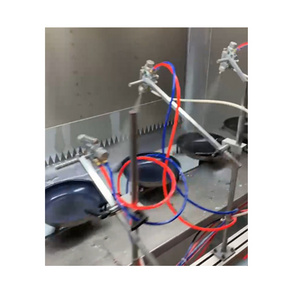

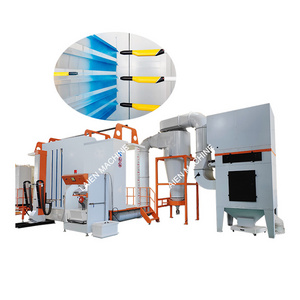

Automatic powder spraying room

The powder is mixed with air in the powder feeder and then sent to the powder gun. The high voltage generated by the high voltage electrostatic generator is connected to the interior or front end of the powder gun. The powder is charged in the interior or outlet of the powder gun. Under the joint action of pneumatic force and electrostatic force, the powder particles are directionally sprayed on the workpiece to be coated. It can also be adsorbed to the back of the workpiece. When the powder attached to the workpiece exceeds a certain thickness, electrostatic repulsion occurs, and the subsequent powder is not easy to be adsorbed to the workpiece surface, so that the workpiece surface reaches a uniform film thickness.

Part of the powder is adsorbed in the cyclone collector under the action of the wind force, and the other part of the powder intermittently pulses the filter element under the action of the secondary filter element pulse controller and solenoid valve to vibrate the powder adsorbed on the surface of the filter element to the powder feeder at the bottom of the chamber for easy cleaning. The equipment is equipped with an automatic recovery system to ensure the normal circulation of powder, reduce powder consumption and save powder.

Frequency conversion reciprocating elevator

Frequency conversion reciprocating elevator: 2 elevators equipped with 8 automatic guns

Main technical indicators:

1) Rated power supply: ac220v-240v/50-60hz

2) Rated power: 0.75kw

3) Reciprocating speed: 0.06-0.6m/s (stepless variable frequency speed regulation)

4) Effective stroke: 2.0m (special customized)

5) Upper and lower limit setting method: digital button adjustment

6) Reducer type: worm

7) Speed regulation mode: variable frequency speed regulation

Manual powder spraying host

● reliable quality and stable operation with extremely low failure rate.

● large and smooth powder output to improve your spraying efficiency.

● the powder application ability at dead corners is very excellent, and it is not easy to leave dead corners.

● anti "powder flushing" design makes the equipment stable when it is opened, without traditional powder flushing, and convenient for manual spraying.

● constant powder output, any pressure change caused by any accumulation in the powder tube will not affect its constant output, and any interference caused by the length and short of the powder tube will not be affected.

Powder curing furnace

the main body of the drying rack is made of square tubes, and the chamber body is a plug-in plate combined bridge insulation structure, which is convenient for transportation and installation.

during installation, 100mm thick rock wool shall be pasted at the joint of furnace plate for insulation to ensure that there is no leakage at the wall joint. The average surface temperature of the outer wall of the drying channel shall not be higher than the ambient temperature by 15 ℃ (when the ambient temperature is 20 ℃).

the assembly plate of the oven chamber is divided into inner plate and outer plate, and the inner plate is selected δ= It is made of 0.5mm galvanized steel plate, and the outer side plate is selected

δ= Made of 0.5mm color plate; Fill between inner and outer panels δ= 120mm rock wool insulation reduces heat transfer.

oven temperature control is to control the working state of the heater by outputting the command signal after comparing the electrical signal measured by the temperature sensor with the set temperature value (analog quantity) through the digital display temperature controller, so as to realize the automatic control / digital display of the furnace temperature.

interlock protection and automatic time delay control are adopted to ensure that the heater can only be turned on when the circulating fan works normally under any circumstances. After the heater stops working, the fan still works for a period of time to blow away the hot gas in the heating room for protection.

hot air circulation in drying furnace 3 times / minute

Power consumption table

|

Serial number

|

Equipment name

|

water t/h(MAX)

|

Electric kw(MAX)

|

Natural gas m3/h(MAX)

|

天然气m3/天

实际耗气量 |

|

1

|

Pretreatment equipment

|

5.0

|

70

|

|

|

|

2

|

Moisture oven

|

|

11

|

50

|

200

|

|

3

|

Powder spraying room

|

|

28

|

|

|

|

4

|

Curing oven

|

|

30

|

140

|

560

|

|

5

|

Conveyor

|

|

9

|

|

|

|

6

|

Other

|

|

/

|

|

|

|

|

Total

|

5.0

|

148

|

1200

|

760

|

Related Machine

Equipment quality assurance

|

type

|

Automatic powder spraying production line

|

|

Substrate

|

metal

|

|

Condition

|

New

|

|

Machine Type

|

JRX Automatic powder coating machine

|

|

Video outgoing-inspection

|

Provided

|

|

Machinery Test Report

|

Provided

|

|

Marketing Type

|

Hot sale

|

|

Warranty of core components

|

1 Year

|

|

Core Components

|

PLC

|

|

Coating

|

powder coating

|

|

Heat Energy

|

Electricity,natural Gas

|

|

Temperature

|

150-300℃

|

|

Air cycle times

|

2-3 times

|

|

Temperature Difference

|

+-5℃

|

|

keywords

|

Automatic powder spraying production line

|

|

Spraying Guns

|

auto spray gun

|

1. The whole line process, equipment layout, overall design and other key technical documents shall be confirmed and signed by Party A and Party B before taking effect.

2. In the design of equipment structure, Party B shall fully consider the convenience of Party A in use, maintenance and repair.

3. After the layout plan is confirmed, Party B can design the component structure and put it into manufacturing.

4. After receiving the equipment ground foundation schematic diagram, "five gas" power point location diagram, roof (side wall) reserved hole location diagram and energy power parameters provided by Party B, Party A shall carefully review and confirm them before organizing the construction.

5. In the process of manufacturing, installation and commissioning, both parties must cooperate closely and cooperate with each other to jointly do a good job in technical quality supervision.

6. Party B must strictly comply with the drawings and technical agreement.

7. During the manufacturing of Party B's equipment, Party A may send personnel to Party B's processing site for inspection at any time.

8. Before the equipment is shipped, Party A shall send personnel to Party B to conduct periodic acceptance on the appearance, materials and manufacturing quality of the equipment.

9. When Party B enters the site for installation and commissioning, Party A shall send personnel to the site to supervise the construction as required, and Party B must actively cooperate with them.

10. Ensure the overall project quality after equipment installation and commissioning.

11. After the formal completion, the warranty period of the equipment is 12 months. In case of equipment quality problems during the warranty period, Party B shall be responsible for providing free services; After the warranty period expires, Party B shall be responsible for providing paid services and lifetime warranty.

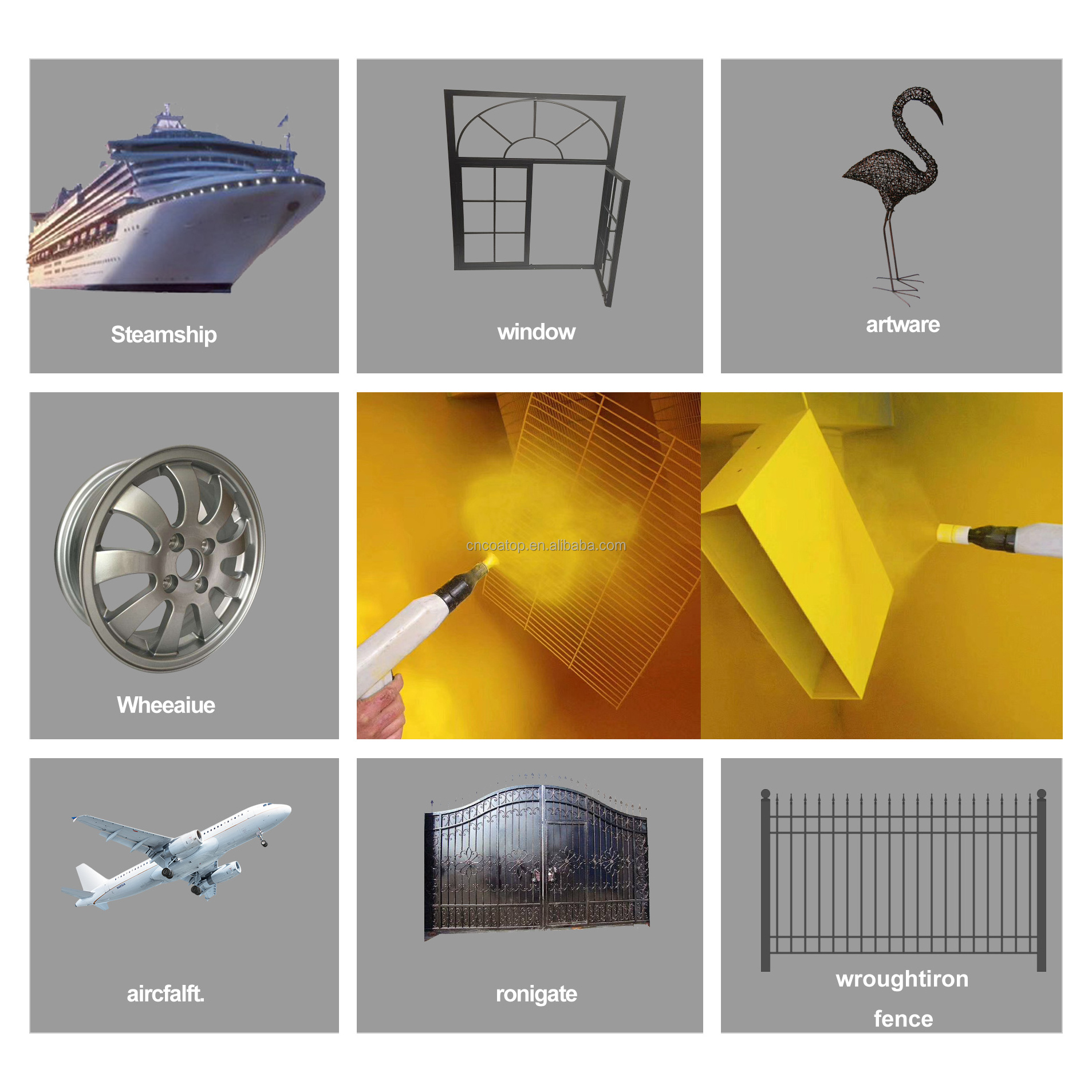

Overseas projects

Hot Searches