- Product Details

- {{item.text}}

Quick Details

-

Air Pressure(MPa):

-

0.5 MPa

-

Heating Power (kW):

-

5.5 kW

-

Air Comsumption(L/min):

-

10 L/min

-

Water Comsumption(L/min):

-

5 L/min

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

unitely

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

4200*1280*1900mm

-

Weight (T):

-

1.5 T

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Speed:

-

15-35 cycles/min

-

Raw material:

-

PET, PVC, HIPS

-

Clean compressed air:

-

With 0.6-1.0 Mpa pressure

-

Air consumption:

-

>0.5 cbm/min

-

Mold cooling water:

-

Tap water or recycle water with 60L/H consumption

-

Mold customized:

-

Supported

-

MOQ:

-

1 Set

Quick Details

-

Max.Forming Height(mm):

-

2800 mm

-

Forming Width (mm):

-

1600 mm

-

Forming Length (mm):

-

1200 mm

-

Air Pressure(MPa):

-

0.5 MPa

-

Heating Power (kW):

-

5.5 kW

-

Air Comsumption(L/min):

-

10 L/min

-

Water Comsumption(L/min):

-

5 L/min

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

unitely

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

4200*1280*1900mm

-

Weight (T):

-

1.5 T

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Speed:

-

15-35 cycles/min

-

Raw material:

-

PET, PVC, HIPS

-

Clean compressed air:

-

With 0.6-1.0 Mpa pressure

-

Air consumption:

-

>0.5 cbm/min

-

Mold cooling water:

-

Tap water or recycle water with 60L/H consumption

-

Mold customized:

-

Supported

-

MOQ:

-

1 Set

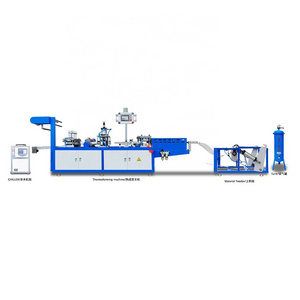

Good quality full automatic plastic cup lid thermoforming machine in pingyang

UNL-DPP450 Automatic plastic thermoforming machine

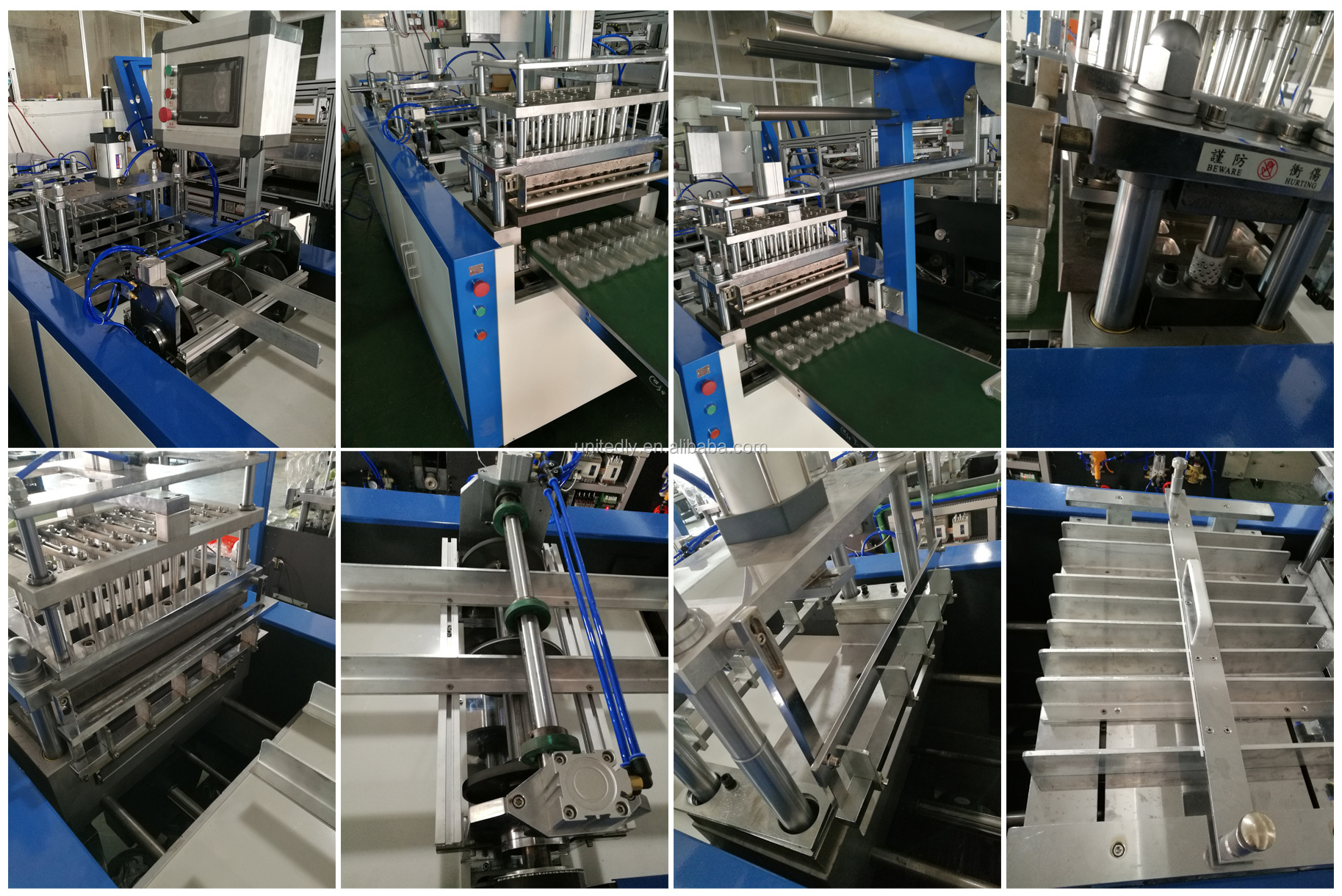

Scope of application:

PET, PS, PVC and other coil production, such as: plastic lid, electronic tray, cosmetics, food, hardware and other packaging products.

Features:

- PLC automatic control system, frequency control.

- Man-machine interface operation.

- Feeding institutions imported, more accurate.

- Large trip, can produce a large number of products.

Main Technical Parameters:

| Speed | 15-35 cyles/min | |

| Material | PET, PVC, HIPS | |

| Requirement | Power | 10KW |

| Clean compressed air | With 0.6-1.0 Mpa | |

| Air consumption | >0.5 cbm/min | |

| Mold colling water |

Tap water or recycle water with 60L/H consumption |

|

| Max forming width | 300mm | |

| Max forming length | 450mm | |

| Max forming depth | 46mm | |

| Overall dimension | 4200*1280*1900mm | |

| Weight | 2200KG | |

Samples:

Packaging details: Wooden case packing

Delivery time: 25-35 days after geting deposit

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

1. What kind of plastic material the machine can work with?

A: In general, the machine can work with PS, PET, PVC and other plastic material

2. How do we design molds?

A: We design the molds according to customers' samples

3. What is the full production process?

A: Plastic sheets heating -- Molds thermoforming -- Holes punching -- Plastic sheets feeding by servo motor -- Knife punching&cutting -- Produts collection

4. Term of payment

A: We accept 100% T/T. 30% of deposit and 70% of balance should be paid before shipment

5. The delivery time of machine

A: Usually within 25-35 days after get deposit and confirm molds