- Product Details

- {{item.text}}

Quick Details

-

Type:

-

Freeze dryer, Dryer

-

Voltage:

-

380V

-

Power:

-

8.5kw

-

Weight:

-

1.5 KG

-

Dimension(L*W*H):

-

1600x1200x2200mm

-

Year:

-

2024

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Application:

-

fruits/root vegetables

-

Function:

-

freeze drying fruit,food,vegetable

-

Usage:

-

food freezee drying test for university or lab

-

Color:

-

Customers' Requirements

-

Capacity:

-

10KG/batch

-

Material:

-

Stainless Steel

-

Vacuum pressure:

-

30-100 Pa

-

Control system:

-

HMI + PLC

Quick Details

-

Marketing Type:

-

New Product 2024

-

Place of Origin:

-

Liaoning, China

-

Brand Name:

-

Xinyang

-

Type:

-

Freeze dryer, Dryer

-

Voltage:

-

380V

-

Power:

-

8.5kw

-

Weight:

-

1.5 KG

-

Dimension(L*W*H):

-

1600x1200x2200mm

-

Year:

-

2024

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Application:

-

fruits/root vegetables

-

Function:

-

freeze drying fruit,food,vegetable

-

Usage:

-

food freezee drying test for university or lab

-

Color:

-

Customers' Requirements

-

Capacity:

-

10KG/batch

-

Material:

-

Stainless Steel

-

Vacuum pressure:

-

30-100 Pa

-

Control system:

-

HMI + PLC

Products Description

What is Freeze dryer

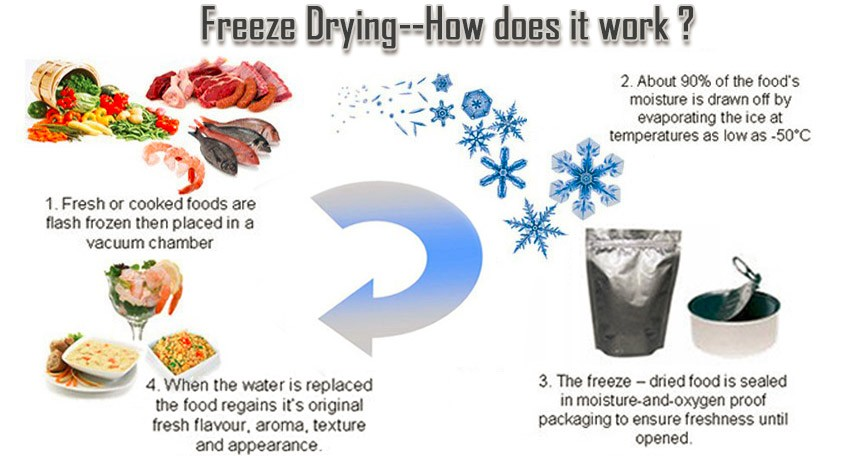

Freeze-drying—technically known as lyophilisation, lyophilization, or cryodesiccation—is a dehydration process typically used to preserve a perishable material or make the material more convenient for transport. Freeze-drying works by freezing the material and then reducing the surrounding pressure to allow the frozen water in the material to sublime directly from the solid phase to the gas phase.

Vacuum freeze drying technology is the most advanced technology for food dehydration processing at present. Compared with the common drying method, the freeze-dried food produced with this technology features long period of quality assurance, good re-hydration nature, good-looking color, good flavor, taste, shape and high content of nutritious components. The dried food basically remains unchanged in its volume and shape, it looks like sponge and has no shrinking. This kind drying technology can be widely used in process of vegetables, fruits, condiments, aquatic products, biological products, medicine, beverage and etc.

Vacuum freeze drying technology is the most advanced technology for food dehydration processing at present. Compared with the common drying method, the freeze-dried food produced with this technology features long period of quality assurance, good re-hydration nature, good-looking color, good flavor, taste, shape and high content of nutritious components. The dried food basically remains unchanged in its volume and shape, it looks like sponge and has no shrinking. This kind drying technology can be widely used in process of vegetables, fruits, condiments, aquatic products, biological products, medicine, beverage and etc.

After Freeze Dry

Advantages of Freeze Dried Food

1. Taste fresh

Freeze-dried foods, like frozen, retain virtually all their fresh-food taste and nutritional content. Freeze-drying removes the water, not the flavor.

2. Look fresh Freeze-dried foods maintain their original shape and texture, unlike dehydrated foods, which shrink and shrivel due to high-temperature processing. Freeze-drying removes water under low temperatures which keeps intact the moisture channels and food fibers. Just add water, and in minutes every fresh food detail returns.

4. Stay fresh Freeze-dried foods can be stored at room temperature, without deterioration or spoilage. This is because freeze-drying and packaging remove both water and oxygen - the two primary causes of food deterioration.

2. Look fresh Freeze-dried foods maintain their original shape and texture, unlike dehydrated foods, which shrink and shrivel due to high-temperature processing. Freeze-drying removes water under low temperatures which keeps intact the moisture channels and food fibers. Just add water, and in minutes every fresh food detail returns.

3. Weigh less than fresh

Freeze-dried foods have 98% of their water removed. This reduces the food's weight by about 90%. Because of its light weight per volume of reconstituted food, freeze-dried products are popular and convenient for hikers. More dried food can be carried per the same weight of wet food, and remains in good condition for longer than wet food, which tends to spoil quickly. Hikers reconstitute the food with water available at point of use.

4. Stay fresh Freeze-dried foods can be stored at room temperature, without deterioration or spoilage. This is because freeze-drying and packaging remove both water and oxygen - the two primary causes of food deterioration.

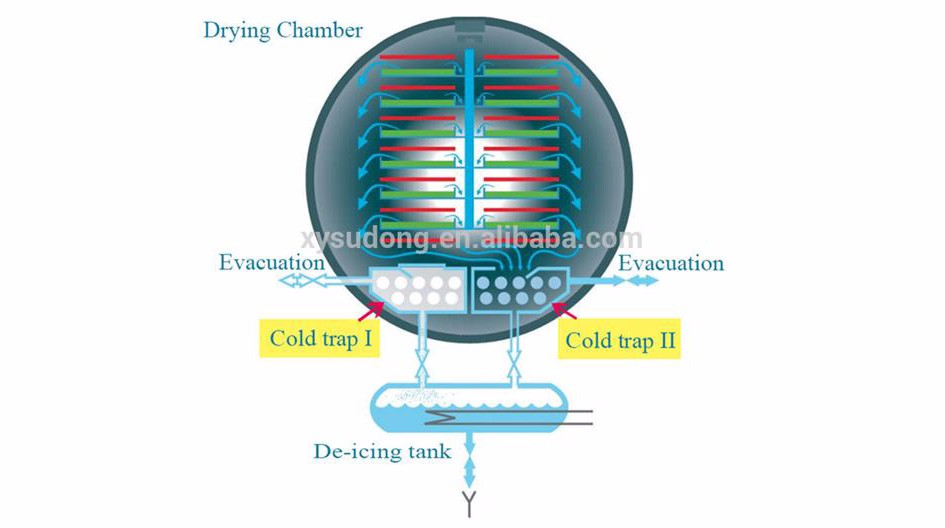

Advantages of Our Freeze Drying Equipment

1. Efficient in heating plates

. The material of heating plates is aviation aluminum after being anodized on the surface, releasing over 100% heat from the product by radiation. This makes heat more uniform and complete.

2. Alternate vapor trap. Double trap is installed under the heating plates in drying chamber. Trap 1 condenses vapor to its maximum capacity, then trap 2 starts to work. In the meantime, trap 1 begins to melt ice for another condensation cycle.

3. Continous de-icing

.

When the trap 2 begins to catch vapor, the trap 1 begins to melt ice on the coil during drying. After melting, the clean coil is ready for another condensation cycle.

4. Automatic control system. Advanced intelligent control system keeps the system running stably and reliably in a long time. Furthermore, simple operation can be much easier to handle.

4. Automatic control system. Advanced intelligent control system keeps the system running stably and reliably in a long time. Furthermore, simple operation can be much easier to handle.

Model &Specification Parameters

Model &Specification

|

Specification Model

|

LG0.2

|

LG1.0

|

LG1.5

|

LG5

|

LG10

|

LG20

|

|

||||||

|

Heating Areas(m2)

|

0.2

|

0.8

|

1.5

|

5.3

|

10

|

20

|

|

||||||

|

Numbers of Vapor trap

|

Single

|

Single

|

Single

|

Single

|

Single

|

Single

|

Double

|

||||||

|

Trapping Capacity(batch)

|

>2kg

|

>8kg

|

>20kg

|

>65kg

|

>130kg

|

>250kg

|

>44kg/hr

|

||||||

|

Heating Medium

|

Electric

|

|

|

Water&electric

|

|

|

Water&Steam

|

||||||

|

Heating Mode

|

Double side radiation

|

|

|

|

|

|

|

||||||

|

Temperature range of Heating plates

|

Normal Temp.~+120℃

|

|

|

<95℃

|

<95℃

|

<95℃

|

Normal Temp.~+130℃

|

||||||

|

Vacuum Pressure (Pa)

|

20~133

|

|

|

|

|

|

|

||||||

|

Need Refrigeration Capacity (t0=-40℃,tk=-35℃) (Kw)

|

With Refrigeration System

|

|

|

|

18

|

35

|

44

|

||||||

|

Consumption of Steam (kg/h)

|

None

|

None

|

None

|

None

|

50

|

None

|

75

|

||||||

|

Electric Power Supply (Kw)

|

3.2

|

8.5

|

15

|

35

|

26

|

65

|

38

|

||||||

|

Tray Numbers

|

2

|

4

|

4

|

14

|

26

|

52

|

54

|

||||||

|

Loading Raw Material(KG)

|

3

|

8

|

20

|

>70

|

>130

|

>260

|

>270

|

||||||

Packing & Delivery

Hot Searches