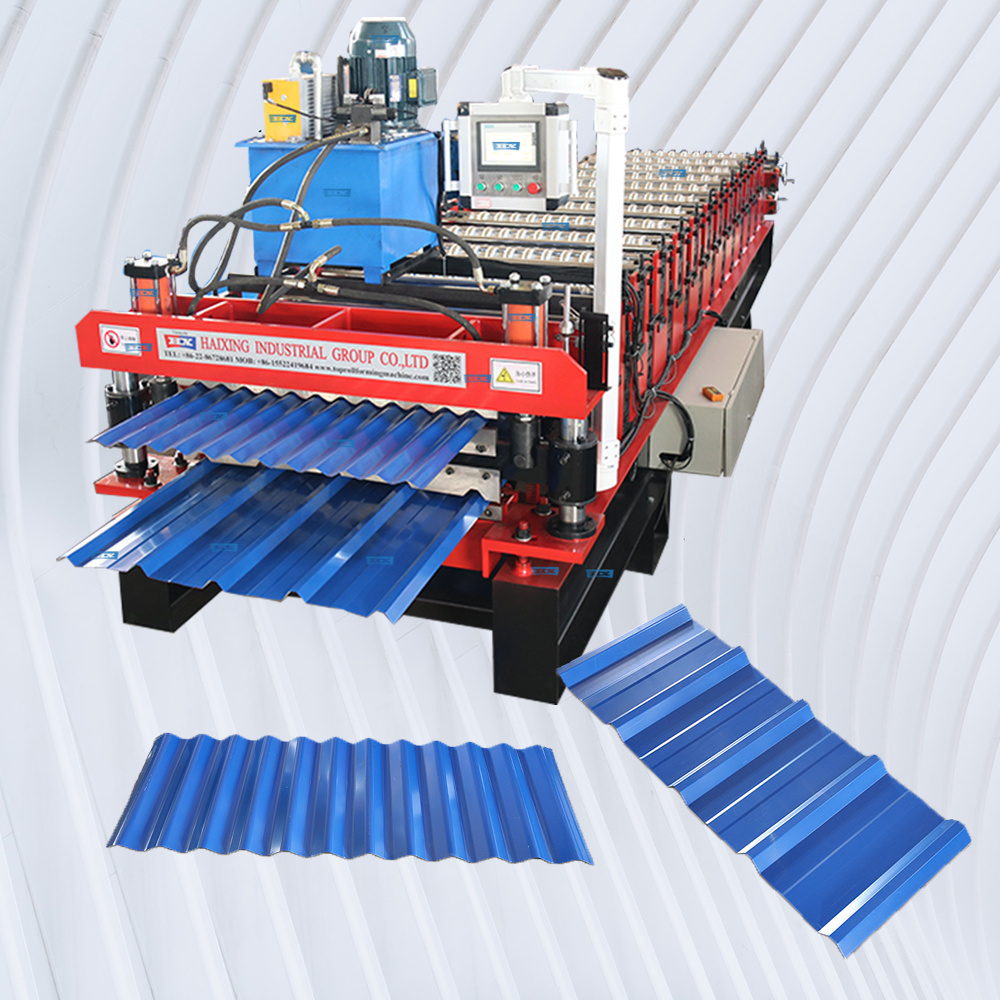

Usage:

Mainly used to support steel coils, and manually uncoil and straighten the coil into the feeding table.

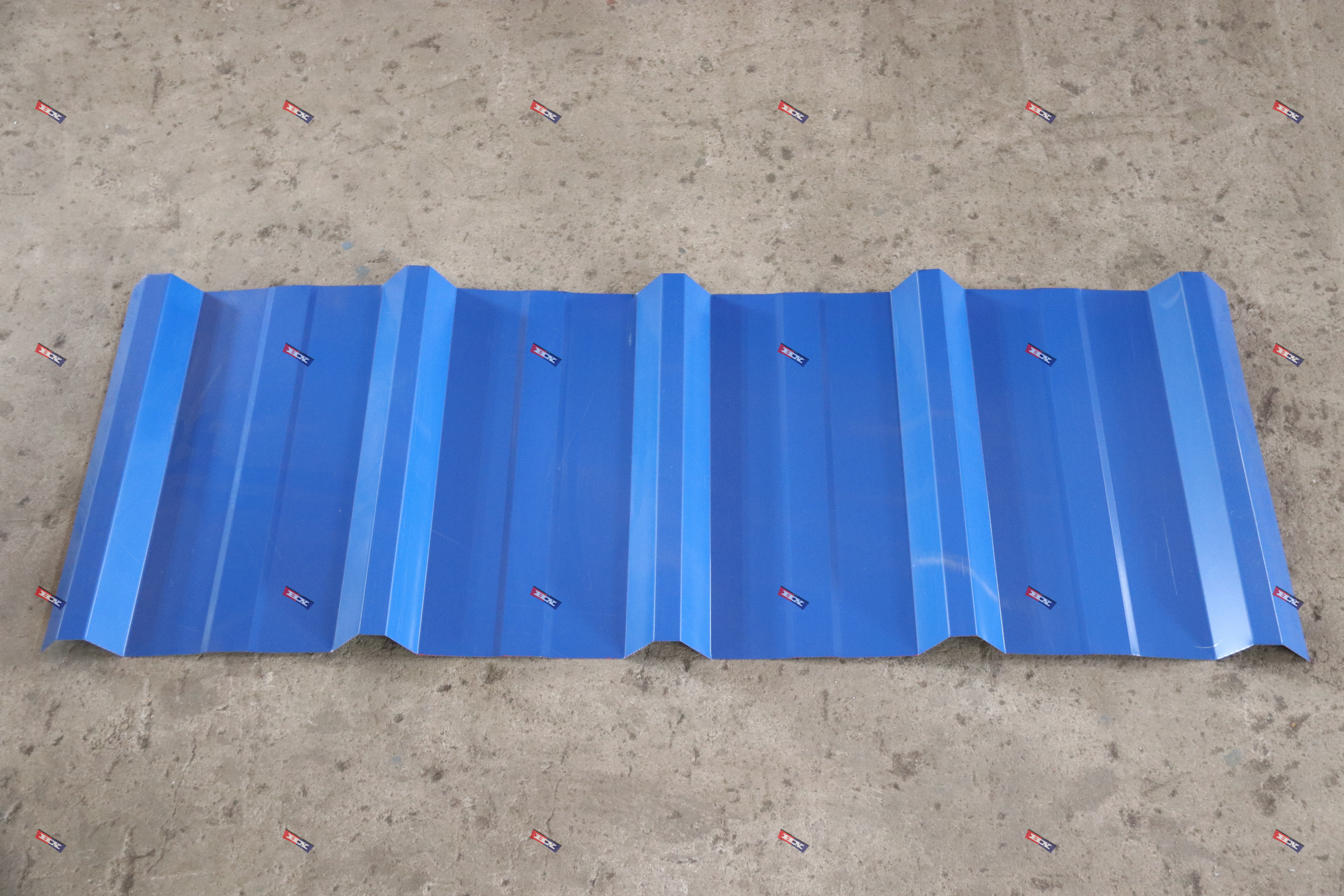

Steel coil width :

940,

1200, 1220 mm. (According to your actual drawing)

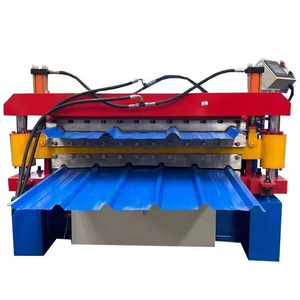

Loading

capacity:

5T

Inner diameter:

500-508mm