- Product Details

- {{item.text}}

Quick Details

-

Power:

-

depends

-

Weight:

-

1200 KG

-

Dimension(L*W*H):

-

L3200 W1850 H2200mm

-

Application:

-

Glass Bottle, Tin, Can Milk, Coffee and Drink

-

Sterilizing way:

-

Hot Water Spraying

-

Function:

-

High Temperature High Pressure Sterilizing

-

Product name:

-

Food Retort Autoclave Sterilizer

-

Keywords:

-

Canning milk retort

-

Heating way:

-

Steam Boiler Heating

-

Usage:

-

Extend Food Shelf Life

-

Advantage:

-

High Efficiency Low Cost

-

Design Temperature:

-

147 Degree Centigrade

-

After-sales Service Provided:

-

Service Machinery Overseas

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

DTS

-

Voltage:

-

220V/380V/415V/440V(or customized)

-

Power:

-

depends

-

Weight:

-

1200 KG

-

Dimension(L*W*H):

-

L3200 W1850 H2200mm

-

Application:

-

Glass Bottle, Tin, Can Milk, Coffee and Drink

-

Sterilizing way:

-

Hot Water Spraying

-

Function:

-

High Temperature High Pressure Sterilizing

-

Product name:

-

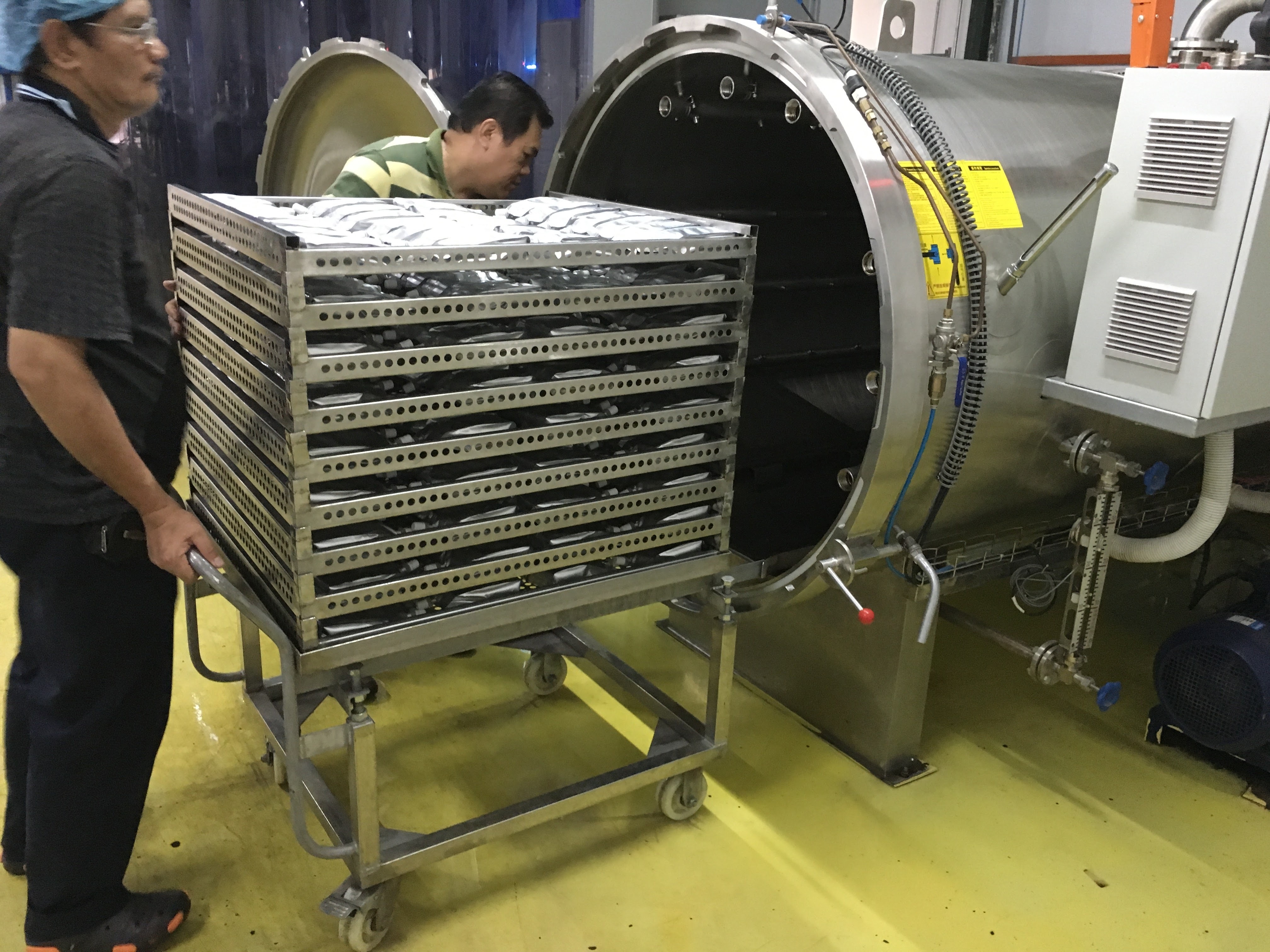

Food Retort Autoclave Sterilizer

-

Keywords:

-

Canning milk retort

-

Heating way:

-

Steam Boiler Heating

-

Usage:

-

Extend Food Shelf Life

-

Advantage:

-

High Efficiency Low Cost

-

Design Temperature:

-

147 Degree Centigrade

-

After-sales Service Provided:

-

Service Machinery Overseas

Limited time discount autoclave canning milk retort

sterilization process

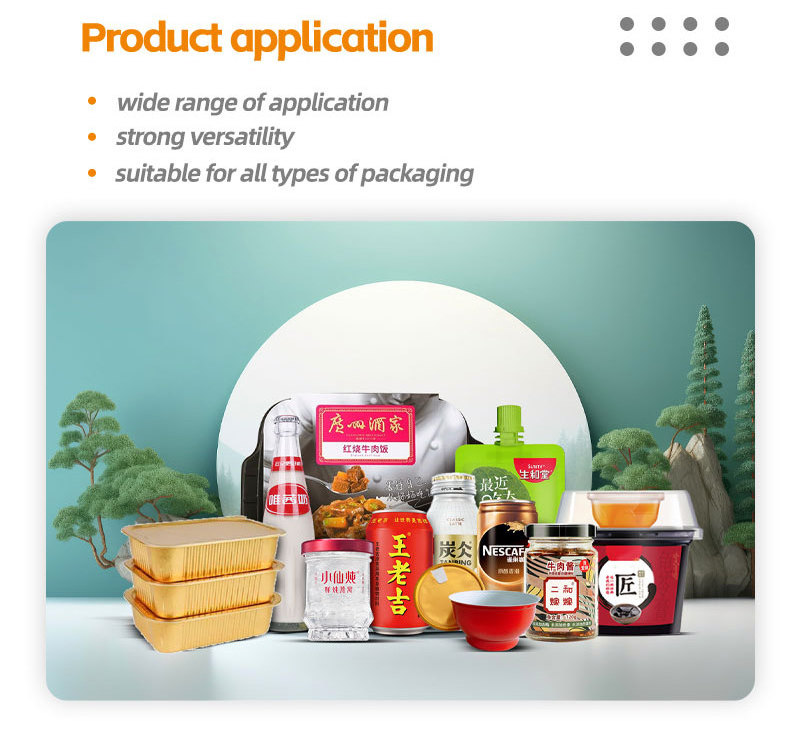

Drinks (vegetable protein, tea, coffee): Tin can; Aluminum can; Aluminum bottle; Plastic bottles, cups; Glass jars; Flexible packaging pouch.

Dairy products: tin cans; plastic bottles, cups; glass bottles; flexible packaging bags

Vegetables and fruits (mushrooms, vegetables, beans): tin cans; glass bottles; flexible packaging bags;

Meat, poultry: tin cans; aluminum cans; flexible packaging bags

Fish and seafood: tin cans; aluminum cans; flexible packaging bags

Baby food: tin cans; glass jars; flexible packaging bags

Ready-to-eat meals: pouch sauces; pouch rice; plastic trays; aluminum foil trays

Pet food: tin can; aluminum tray; plastic tray; flexible packaging bag;

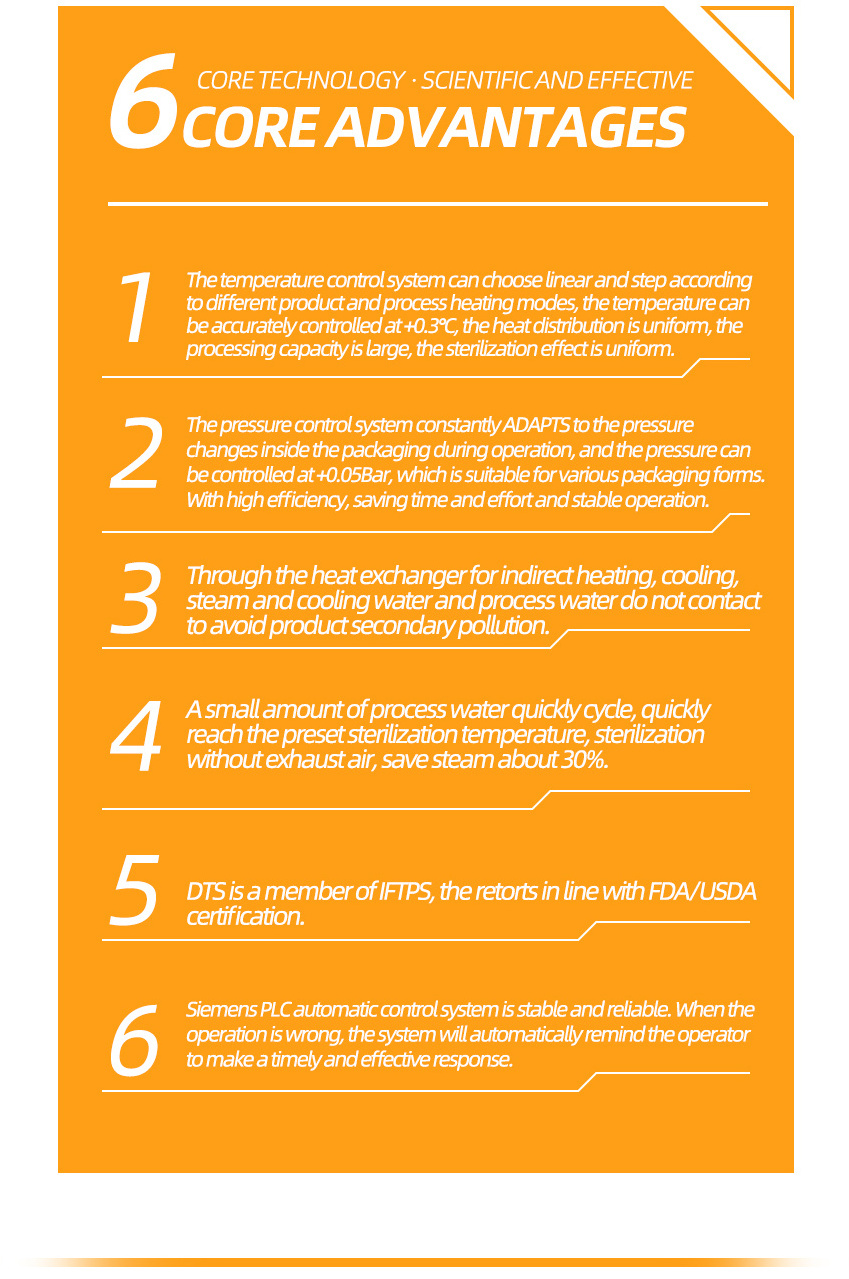

Advantage of water spray retort

Accurate temperature control, excellent heat distribution

The temperature can be controlled within ±0.5℃.

Perfect pressure control, suitable for a variety of packaging forms

Highly clean product packaging

Compliant with FDA/USDA certificate

Energy saving and environmental protection

There is no need to vent before heating, which greatly saves steam loss and saves about 30% of steam.