- Product Details

- {{item.text}}

Quick Details

-

Product Name:

-

Spiral Heat Exchanger

-

Application:

-

Steam condensation

-

Plate material:

-

Stainless Steel

-

Packing:

-

Plywood Case

-

Feature:

-

High Heat Transfer

-

Product Type:

-

Industrial Heat Exchanger

-

Design pressure:

-

2.5MPA

Quick Details

-

Structure:

-

Plate Heat Exchanger

-

Voltage:

-

220V/380V

-

Place of Origin:

-

Shandong, China

-

Product Name:

-

Spiral Heat Exchanger

-

Application:

-

Steam condensation

-

Plate material:

-

Stainless Steel

-

Packing:

-

Plywood Case

-

Feature:

-

High Heat Transfer

-

Product Type:

-

Industrial Heat Exchanger

-

Design pressure:

-

2.5MPA

Stainless steel 304 316 Spiral plate heat exchanger in chemical plant for nuclear power plant with easy install

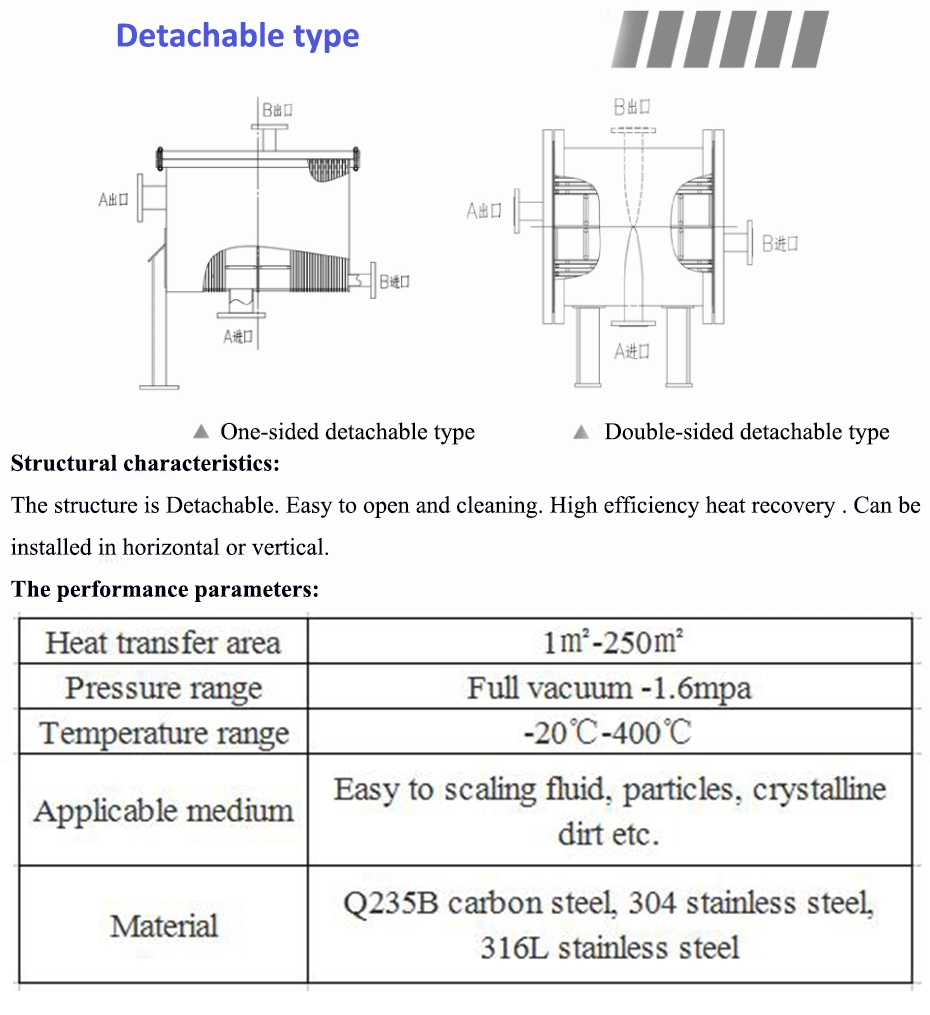

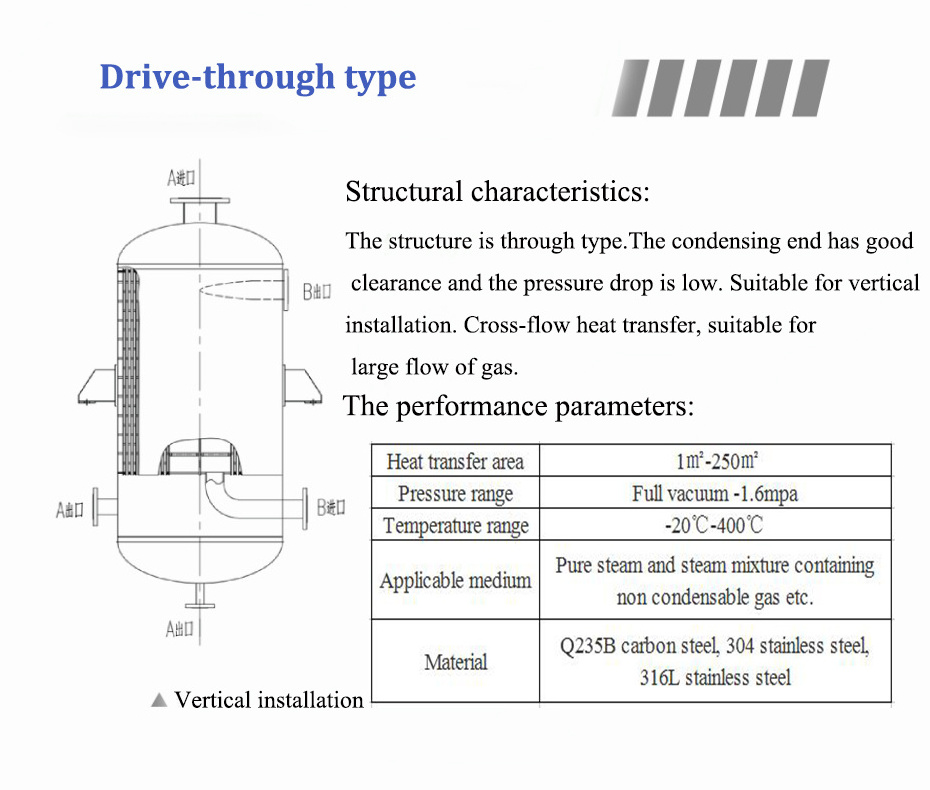

Spiral H eat E xchanger (SHE) is a high-efficiency heat exchanger suitable for steam-steam, steam-liquid and liquid-liquid heat transfer. It adapts for chemical, petroleum, pharmacy, food, light-industry, textile, metallurgy, steel rolling and coking industry etc. According to the structure, it can be divided into un-detachable (Model I) and detachable (Model III) SHE.

Description

Spiral Heat Exchanger (SHE) is a kind of heat exchanger, which is made of two parallel metal plates and made into two spiral channels. The heat and cold fluid exchange through the spiral plate wall. There are two types of spiral plate heat exchanger: detachable and non detachable.

Parameters of Spiral heat exchanger

|

Model |

Heat Exchange Area F(m2) |

Channel Space b(mm) |

O.D. of Shell D(mm) |

Size of Support E×F(mm) |

Size of Nozzles DN(mm) |

Weight (kg) |

|

|

PLC30P-750-12/12 |

30 |

12/12 |

986 |

400×600 |

65/65 |

65/65 |

1385 |

|

PLC30P-1260-18/18 |

18/18 |

918 |

850×600 |

80/80 |

80/80 |

1610 |

|

|

PLC45P-750-14/14 |

45 |

14/14 |

1206 |

850×800 |

65/65 |

80/80 |

2035 |

|

PLC45P-1260-18/18 |

18/18 |

1095 |

850×700 |

80/80 |

100/100 |

2230 |

|

|

PLC60P-1260-14/14 |

60 |

14/14 |

1161 |

850×700 |

100/100 |

125/125 |

2755 |

|

PLC60P-1260-20/20 |

20/20 |

1295 |

850×800 |

100/100 |

125/125 |

3030 |

|

|

PLC90P-1260-15/15 |

90 |

15/15 |

1389 |

850×900 |

100/100 |

125/125 |

3900 |

|

PLC90P-1260-20/20 |

20/20 |

1535 |

850×1000 |

100/100 |

125/125 |

4125 |

|

|

PLC120P-1260-14/14 |

120 |

14/14 |

1593 |

850×1000 |

100/100 |

125/125 |

5160 |

|

PLC120P-1260-20/20 |

20/20 |

1779 |

850×1100 |

125/125 |

150/150 |

5635 |

|

|

PLC120P-1500-25/25 |

25/25 |

1759 |

1000×1100 |

125/125 |

150/150 |

6025 |

|

Feature

1. Good heat transfer efficiency

2. It has self-cleaning function

3. Good sealing performance of non detachable structure

4. It is good for heat transfer with small temperature difference and suitable for recovery of heat energy at low temperature

5. Compact structure

6. The spiral channel has elastic free expansion and small temperature difference stress.

7. Low price

Product Details

Related Product

Package and Shipping

About Us

Propellent, as the promoter and one of the leaders of effective heat exchanger technology, has been designing and manufacturing heat exchangers for decades of years. Propellent offers a full range of heat exchangers and heat transfer services in all type of industries. To achieve high efficiency at low operating costs, greater application possibilities at a lower investment costs. Customized solutions are provided to match the customers' requirements.

We also offer abundant types of replacement parts for plate heat exchangers, these spare parts apply to international brands in all direction, such as GEA, APV, Sondex, Tranter, Vicarb, Hisaka, API etc, to meet our clients' demand all over the world.

Click Here To Learn More Information

Certification

Contact us

Thanks for your visiting propellent heat exchangers.

If you have any requirements, kindly please feel free to contact us