- Product Details

- {{item.text}}

Quick Details

-

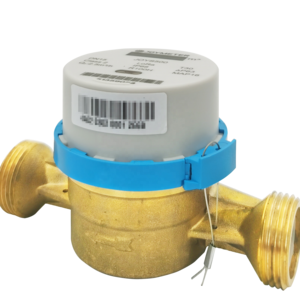

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

XuXinDa

-

Model Number:

-

LXSY

-

Size:

-

DN15/DN20/DN25

-

Pipe material:

-

copper

Quick Details

-

Warranty:

-

3 years

-

Type:

-

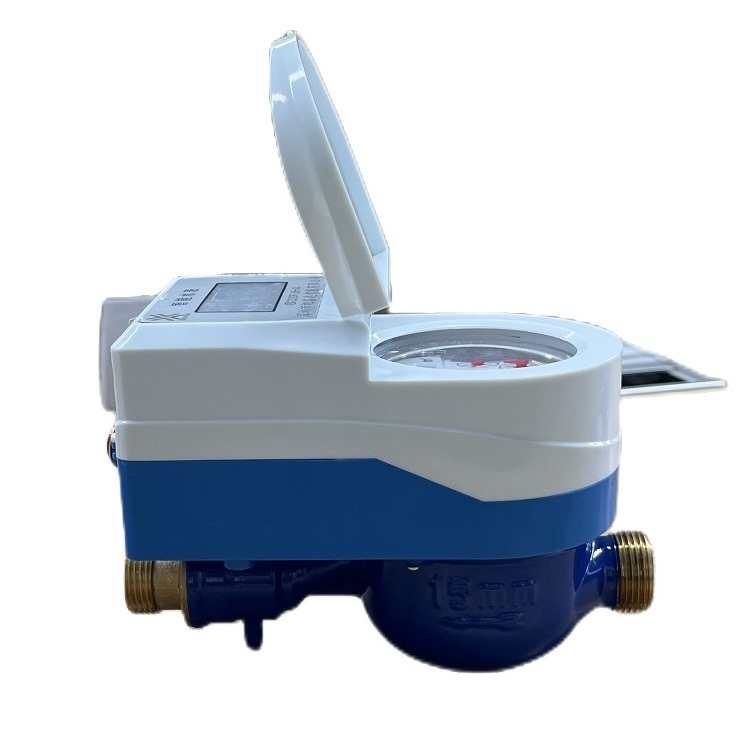

Multi-jet meters, Prepaid water meters, Digital

-

Material:

-

brass

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

XuXinDa

-

Model Number:

-

LXSY

-

Size:

-

DN15/DN20/DN25

-

Pipe material:

-

copper

Product Description

Specification

|

Nominal caliber

|

DN15

|

DN20

|

DN25

|

||

|

Overload Flow(Q4)

|

3.125m

3

/h

|

5.0m

3

/h

|

7.875m3/h

|

||

|

Common Flow Rate (Q3)

|

2.5m

3

/h

|

4.0m

3

/h

|

6.3m3/h

|

||

|

Demarcation flow rate (Q2)

|

0.05m

3

/h

0.04m

3

/h

|

0.08m

3

/h

0.064m

3

/h

|

0.128m

3

/h

1.008m

3

/h

|

||

|

Minimum Flow Rate (Q1)

|

0.0312m

3

/h

0.025m

3

/h

|

0.05m

3

/h

0.04m

3

/h

|

0.08m

3

/h

0.63m

3

/h

|

||

|

Turndown ratio (Q3/Q1)

|

80、100

|

|

|

||

|

Quiescent current

|

≤5uA

|

|

|

||

|

Working water pressure

|

0.03-1 MPa

|

|

|

||

|

Ambient temperature

|

5°C-55°C

|

|

|

||

|

relative humidity

|

≤100%RH

|

|

|

||

|

Pressure loss rating

|

△ P63(≤0.063MPa)

|

|

|

||

|

Installation:

|

Horizontal(H)

|

|

|

||

|

Operating temperature

|

Cold water meter:T30 Hot water meter:T90

|

|

|

||

|

Indication error

|

Low zone:≤±5% (cold、hot) High zone:≤±2% (cold), ≤±3% (hot)

|

|

|

||

|

Base surface material

|

brass

|

|

|

||

|

Accuracy rating

|

2 class

|

|

|

||

|

Minimum reading

|

Mechanical readings:0.0001 m

3

Electronic readings:0.01m³

|

|

|

||

|

Maximum reading

|

Mechanical readings:99999m

3

Electronic readings:99999.99m³

|

|

|

||

|

Power supply mode

|

Lithium sub-batteries:ER18505M Voltage:3.6v

|

|

|

||

|

Enclosure protection rating

|

Waterproof rating:IP68

|

|

|

||

Product Paramenters

|

Nominal diameter DN (mm)

|

Length L1 (mm)

|

Length L2 (mm)

|

Width W(mm)

|

Height H(mm)

|

Nut G

|

Pipe R

|

|

DN15

|

165

|

260

|

84

|

87

|

G3/4B

|

R1/2

|

|

DN20

|

195

|

300

|

84

|

87

|

G1 B

|

R3/4

|

|

DN25

|

225

|

320

|

84

|

127

|

G1 1/4B

|

G1 B

|

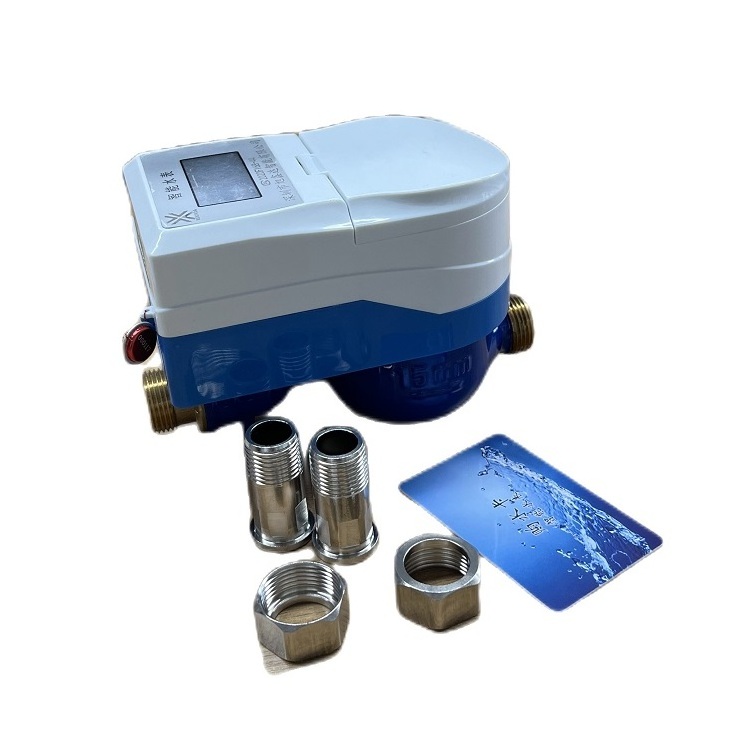

Installation Instructions

1.

The caliber of the water meter should be selected according to the flow rate of the installation site.

2. The installation location should avoid exposure, freezing, pollution, humidity and flooding, so as to disassemble and read the meter, during the freezing period, in addition to wrapping the water meter and water pipe, when not in use, the water meter inlet valve is closed, and the water outlet valve and faucet are opened, which can prevent the water meter from being damaged due to freezing expansion.It is recommended to install it in a special water meter box.

3. The water meter must be installed horizontally so that the literal face up and the direction of the arrow is the same as the direction of the water flow.

4. The newly installed pipeline must be washed clean of stones, sediment, hemp silk and other sundries in the pipeline before installing the water meter, so as not to cause water meter failure.

5. For accurate metering, the faucet should be higher than the water meter.

6. If the water meter is installed at the boiler inlet pipe, it should prevent the hot water from flowing back and scalding the water meter.

7. The water meter should not be directly connected with the pipeline, and the water meter and the pipe should be connected by pipes, sealing gaskets, and connecting nuts. When disassembling and assembling the water meter, do not use a hard wrench to avoid twisting the case.

8. The water meter is used for a long time, and the impurities and rust in the pipeline will block the filter screen or enter the water meter, so that the error of the water meter will increase or affect the normal operation, it is best to wash it every three years and recalibrate it, but do not disassemble and assemble it by yourself.

9. When no water is used, if there is a slight movement, it is caused by the unstable water flow pressure in the pipeline or other reasons.

2. The installation location should avoid exposure, freezing, pollution, humidity and flooding, so as to disassemble and read the meter, during the freezing period, in addition to wrapping the water meter and water pipe, when not in use, the water meter inlet valve is closed, and the water outlet valve and faucet are opened, which can prevent the water meter from being damaged due to freezing expansion.It is recommended to install it in a special water meter box.

3. The water meter must be installed horizontally so that the literal face up and the direction of the arrow is the same as the direction of the water flow.

4. The newly installed pipeline must be washed clean of stones, sediment, hemp silk and other sundries in the pipeline before installing the water meter, so as not to cause water meter failure.

5. For accurate metering, the faucet should be higher than the water meter.

6. If the water meter is installed at the boiler inlet pipe, it should prevent the hot water from flowing back and scalding the water meter.

7. The water meter should not be directly connected with the pipeline, and the water meter and the pipe should be connected by pipes, sealing gaskets, and connecting nuts. When disassembling and assembling the water meter, do not use a hard wrench to avoid twisting the case.

8. The water meter is used for a long time, and the impurities and rust in the pipeline will block the filter screen or enter the water meter, so that the error of the water meter will increase or affect the normal operation, it is best to wash it every three years and recalibrate it, but do not disassemble and assemble it by yourself.

9. When no water is used, if there is a slight movement, it is caused by the unstable water flow pressure in the pipeline or other reasons.

Factory Bulk

Hot Searches