- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

1-2%

-

Packaging Type:

-

Contact us, Tube

-

Place of Origin:

-

Sao Paulo, Brazil

-

Brand Name:

-

PROFILLS

-

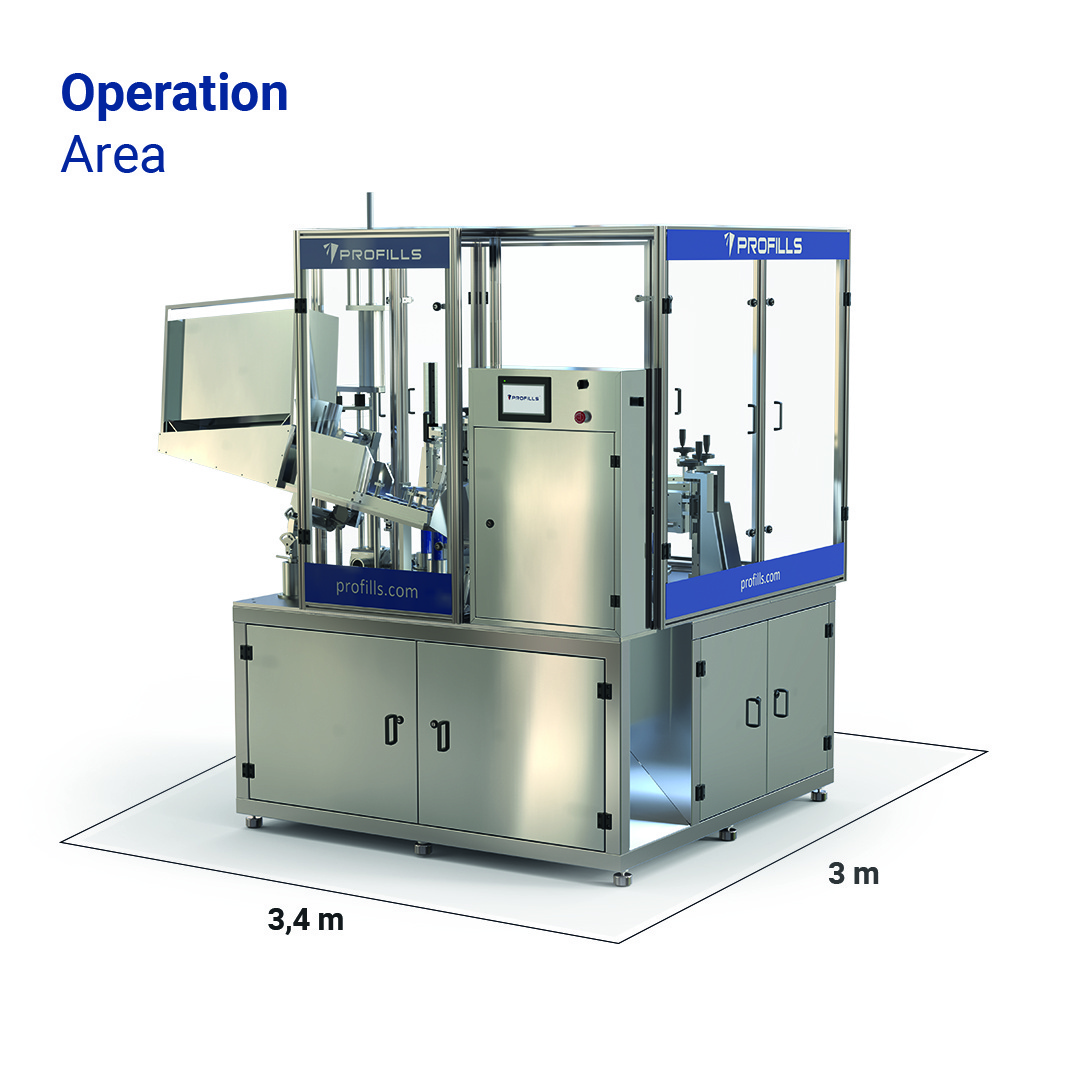

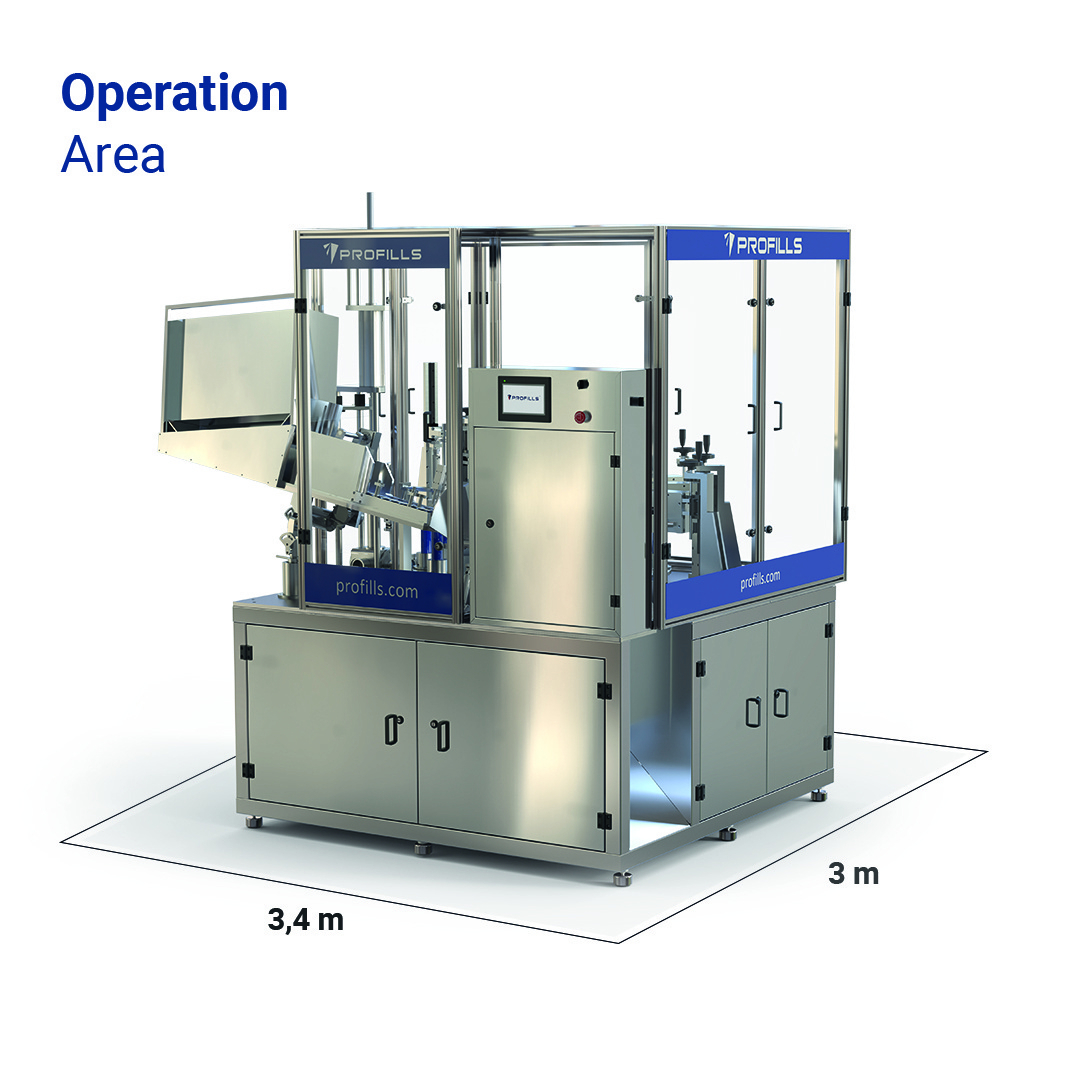

Dimension(L*W*H):

-

3,400x3,000 mm

-

Weight:

-

200 KG

Quick Details

-

Machinery Capacity:

-

1800 units

-

Packaging Material:

-

Plastic, Metal, Contact us, PET

-

Filling Material:

-

Beer, Other, Milk, Water, Oil, Juice, Powder, Liquid

-

Filling Accuracy:

-

1-2%

-

Packaging Type:

-

Contact us, Tube

-

Place of Origin:

-

Sao Paulo, Brazil

-

Brand Name:

-

PROFILLS

-

Dimension(L*W*H):

-

3,400x3,000 mm

-

Weight:

-

200 KG

Product Description

PROFILLS TUBE FILLING MACHINE

Applications: The ProFills Tube Filling Machine is indispensable for industries requiring efficient and precise tube filling. It's the preferred choice for cosmetics, pharmaceuticals, food processing, and chemical sectors. Whether you're packaging lip balms, ointments, purees, or chemical gels, this machine ensures optimal filling for a wide range of products.

Key Features:

* Advanced orientation and positioning system for consistent tube handling.

* Versatile filling options to accommodate different product consistencies.

* Multiple sealing methods to suit various tube materials.

* Streamlined operation for consistent quality and quantity output.

Main Components:

Constructed with top-tier components from globally recognized brands such as Festo, Omron, and Autonics. The machine comprises a feeding system, orientation system, filling mechanism, sealing unit, and an ejection system, ensuring reliability and top-tier performance.

Customizable Sachet Sizes: Designed to handle a variety of tube sizes and shapes, offering adaptability to cater to specific packaging requirements.

Benefits:

Applications: The ProFills Tube Filling Machine is indispensable for industries requiring efficient and precise tube filling. It's the preferred choice for cosmetics, pharmaceuticals, food processing, and chemical sectors. Whether you're packaging lip balms, ointments, purees, or chemical gels, this machine ensures optimal filling for a wide range of products.

Key Features:

* Advanced orientation and positioning system for consistent tube handling.

* Versatile filling options to accommodate different product consistencies.

* Multiple sealing methods to suit various tube materials.

* Streamlined operation for consistent quality and quantity output.

Main Components:

Constructed with top-tier components from globally recognized brands such as Festo, Omron, and Autonics. The machine comprises a feeding system, orientation system, filling mechanism, sealing unit, and an ejection system, ensuring reliability and top-tier performance.

Customizable Sachet Sizes: Designed to handle a variety of tube sizes and shapes, offering adaptability to cater to specific packaging requirements.

High Efficiency:

With its advanced design and seamless operation, this machine boosts production rates, reduces waste, and ensures consistent filling.

Widely Applicable:

From cosmetic creams and pharmaceutical ointments to food pastes and chemical gels, this machine's versatility makes it suitable

for a broad range of industries.

for a broad range of industries.

Low Maintenance:

Thanks to the use of renowned brands and automated CNC machines for milled parts, the machine promises durability with minimal maintenance.

Benefits:

*

Labor Cost Reduction: Automated filling reduces the need for manual labor, leading to significant cost savings.

* Consistent Quality: Ensures that products are packaged with uniform quality, enhancing brand reputation.

* Waste Reduction: Precise filling mechanisms minimize product wastage.

* Cost-Effective: With its robust construction, low maintenance needs, and efficient operation, this machine offers a high return on investment over time.

* Enhanced Positioning on the Shelf: Consistent and professional packaging ensures your product stands out on store shelves, drawing more customer attention.

* Higher-production: Built for high-volume operations, this machine ensures you can meet market demands swiftly and efficiently.

* Less safety risks to workers: Designed with safety in mind, this machine minimizes operational risks, ensuring a safe working environment.

* Product safety: By utilizing precise filling and secure sealing mechanisms, the machine guarantees that each tube is filled accurately and sealed tightly, preserving product quality and preventing potential leaks or contamination.

* Consistent Quality: Ensures that products are packaged with uniform quality, enhancing brand reputation.

* Waste Reduction: Precise filling mechanisms minimize product wastage.

* Cost-Effective: With its robust construction, low maintenance needs, and efficient operation, this machine offers a high return on investment over time.

* Enhanced Positioning on the Shelf: Consistent and professional packaging ensures your product stands out on store shelves, drawing more customer attention.

* Higher-production: Built for high-volume operations, this machine ensures you can meet market demands swiftly and efficiently.

* Less safety risks to workers: Designed with safety in mind, this machine minimizes operational risks, ensuring a safe working environment.

* Product safety: By utilizing precise filling and secure sealing mechanisms, the machine guarantees that each tube is filled accurately and sealed tightly, preserving product quality and preventing potential leaks or contamination.

Specification

|

Technical Information

|

|

|

|

Production Capacity

|

Up to 1800 units/hour Variable according to packaging and product density

|

|

|

Dating system

|

Inkjet

|

|

|

Dosing system

|

Extruder press / Positive pump / Volumetric

|

|

|

Operating Voltage

|

220 [V] - 60 [Hz]

|

|

|

Installed Active Power

|

6,00 [kW]

|

|

|

Active Power Consumed

|

4.85 [kW.h]

|

|

|

Command

|

PLC with Touchscreen HMI

|

|

|

Air Consumption

|

255 [L/min]

|

|

|

Area of Operation

|

3,400x3,000 [mm²]

|

|

|

Manufacturing Material

|

AISI 304 stainless steel, aluminum, polycarbonate and carbon steel

|

|

|

Tube Diameter

|

10 to 52 [mm]

|

|

|

Tube Length

|

60 to 250 [mm]

|

|

|

Tube Volume

|

1.5 to 350 [mL]

|

|

|

Closure System

|

Manual or automatic

|

|

|

Compatible Packaging

|

Tubes, plastic and metal

|

|

|

Filling Product

|

Liquids

|

|

Packing & Delivery

Sea Worthy Crates

Hot Searches